N-i-n type electro-optic modulator

An electro-optic modulator, n-i-n technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of inability to form current blocking, difficult electric field electro-optic modulation, and reduce modulation efficiency, so as to improve the secondary electro-optic effect and reduce leakage current , the effect of improving the modulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

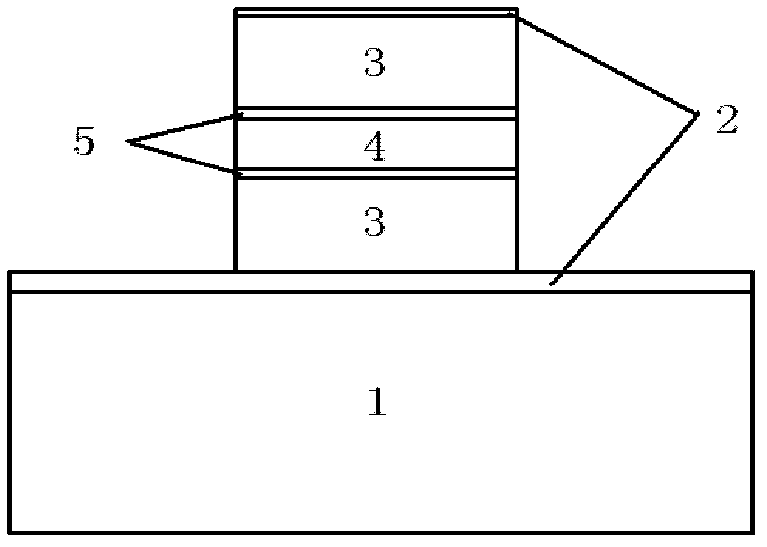

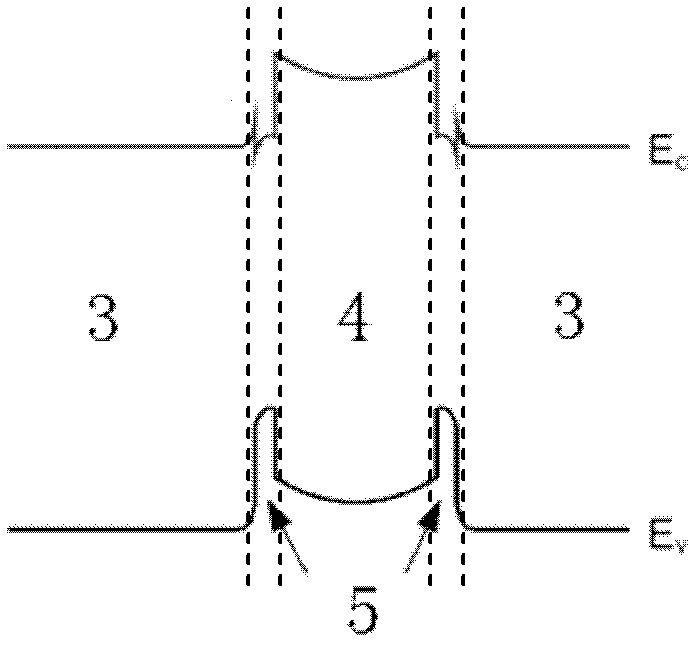

[0028] Such as Figure 3a Shown is the structure of the InP-InAlAs-InP semiconductor electro-optic modulator based on InP, and its energy band structure diagram is as follows Figure 3b shown. Wherein, the confinement layer is an N-type doped InP confinement layer 13 with a doping concentration of 10 17 order of magnitude. The ohmic contact layer is made of N-type doped InGaAs material, which is the N-type doped InGaAs ohmic contact layer 10 . The active layer (also known as the active region) uses InP lattice-matched InAlAs (E g =1.45eV) bulk material is the InAlAs active layer 11, the waveguide width is 2um, and the thickness of the InAlAs active layer 11 is 390nm. On both sides of the InAlAs active layer 11, InGaAsP (E g =0.95eV) The purpose of the waveguide layer 12 is to confine the light field more effectively. In order to reduce the electrical loss of the microwave signal, the substrate is a semi-insulating InP substrate 9, and the waveguide adopts a high ridge st...

Embodiment 2

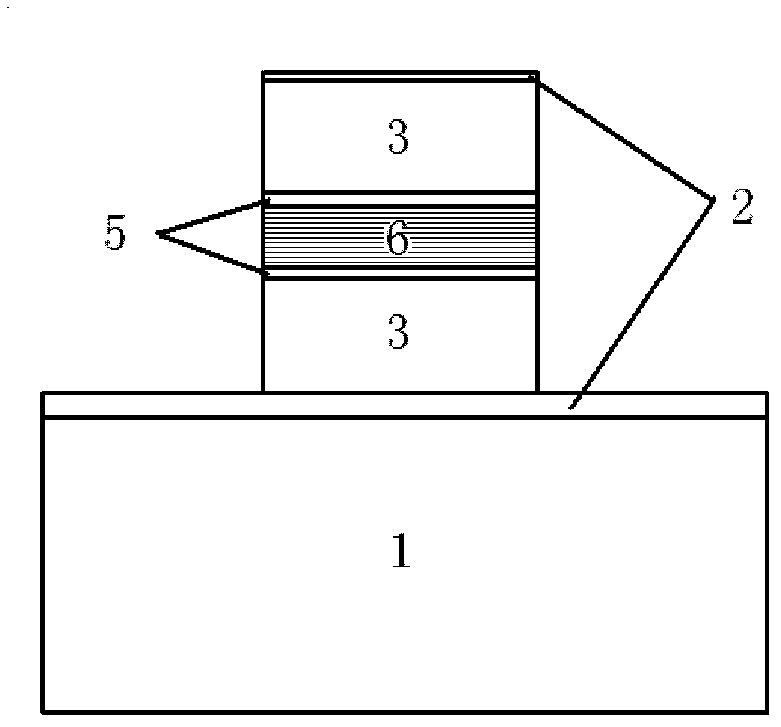

[0036] Such as Figure 4a As shown, the active layer can use 20 cycles of InGaAsP (E g =0.95eV) / InAlAs(E g =1.45eV) n-i-n structure of quantum wells, which is N-type doped InGaAsP / InAlAs (' / ' represents quantum wells, the left side of ' / ' is a well, and the right side is a barrier) multi-quantum well active layer 14, the total of the active layer The thickness is 390nm. In order to effectively confine the optical field, a 50nm InGaAsP (E g =0.95eV) waveguide layer 12 . Since InGaAsP(E g =0.95eV) / InAlAs(E g =1.45eV) The potential barrier formed by multiple quantum wells not only has the effect of blocking leakage current, but also because the energy band structure of multiple quantum wells can form a certain reflection on electrons, the energy band structure in the case of quantum wells can be more effectively Block leakage current. Through calculation, it can be concluded that the leakage current of the quantum well structure is an order of magnitude smaller than that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com