Electro-optic modulator and manufacturing method thereof

An electro-optical modulator, metal electrode technology, applied in instruments, optics, nonlinear optics, etc., can solve problems such as microwave loss, achieve high-efficiency electric field loading, solve microwave loss, and improve modulation characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

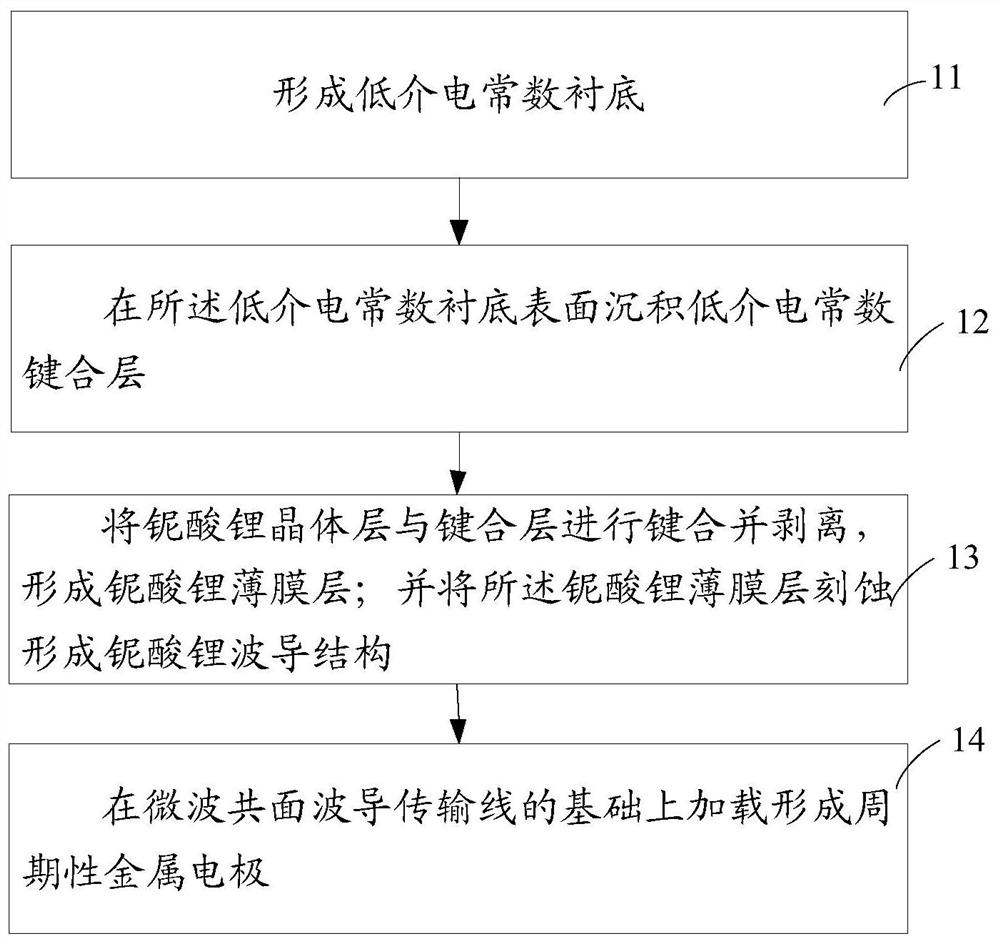

[0020] figure 1 It is a schematic flow chart of a manufacturing method of an electro-optic modulator according to an embodiment of the present invention, the method comprising:

[0021] Step 11, forming a low dielectric constant substrate;

[0022] The low dielectric constant substrate is quartz crystal with a thickness ranging from 100um to 500um.

[0023] Step 12, depositing a low dielectric constant bonding layer on the surface of the low dielectric constant substrate;

[0024] The low dielectric constant bonding layer is a silicon dioxide layer or a benzocyclobutene (BCB) layer with a thickness ranging from 2um to 10um.

[0025] Step 13, bonding and peeling off the lithium niobate crystal layer and the bonding layer to form a lithium niobate thin film layer; and etching the lithium niobate thin film layer to form a lithium niobate waveguide structure;

[0026] Wherein, the thickness of the lithium niobate thin film layer ranges from 400nm to 800nm. When etching the lit...

Embodiment 2

[0039] Figure 4 It is a schematic flow chart of the manufacturing method of the second electro-optic modulator of the present invention, combined below Figure 4a to Figure 4e The specific structural schematic diagram in the method preparation is described in detail. The method includes:

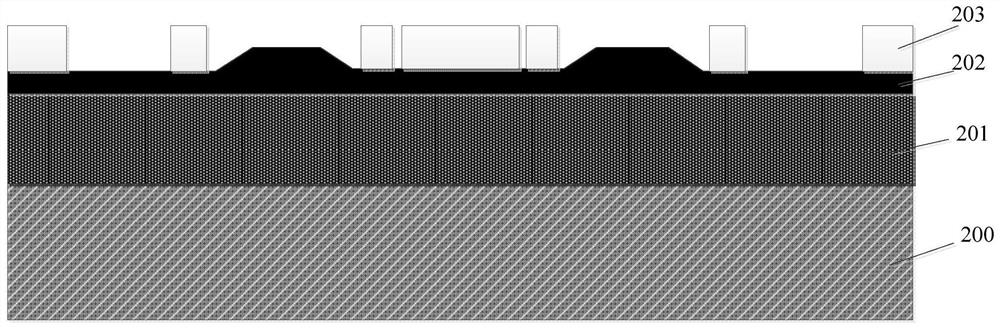

[0040] Step 41, such as Figure 4a As shown, a low dielectric constant substrate 200 is formed;

[0041] The low dielectric constant substrate is quartz crystal with a thickness ranging from 100um to 500um.

[0042] Step 42, such as Figure 4b As shown, a low dielectric constant bonding layer 201 is deposited on the surface of the low dielectric constant substrate;

[0043] The low dielectric constant bonding layer is a silicon dioxide layer or a benzocyclobutene (BCB) layer with a thickness ranging from 2um to 10um.

[0044] Step 43, such as Figure 4cAs shown, the lithium niobate crystal layer and the bonding layer are bonded and peeled off to form a lithium niobate thin film layer...

Embodiment 3

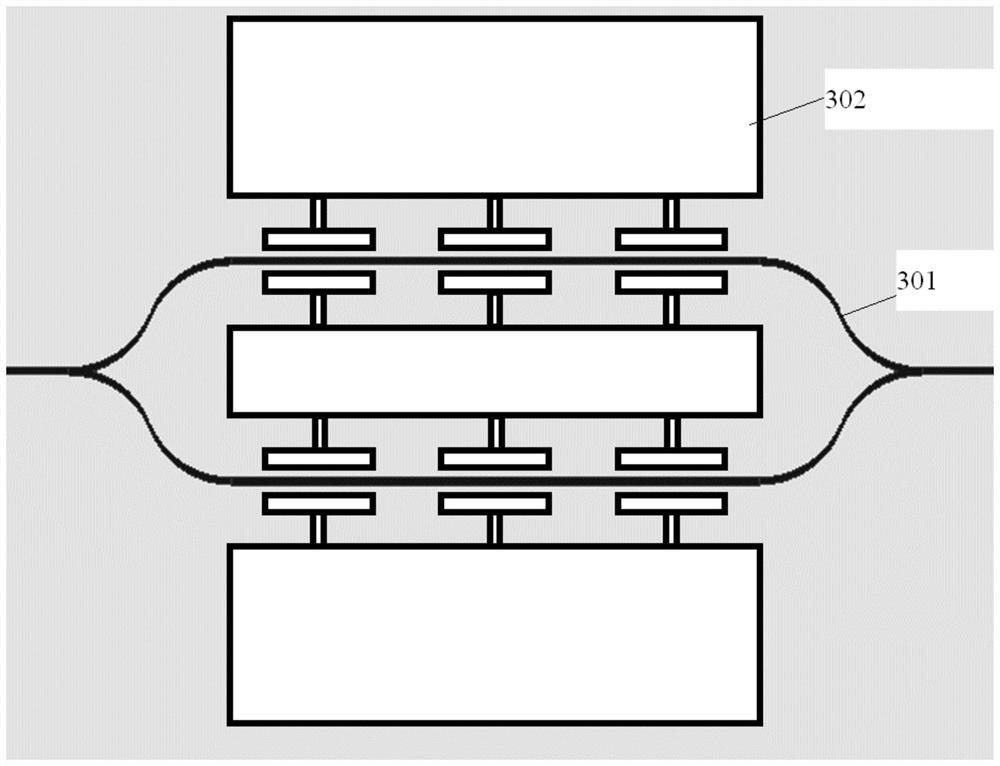

[0052] Figure 5 It is a schematic flow chart of a method for manufacturing an electro-optic modulator according to Embodiment 3 of the present invention, and the method includes:

[0053] Step 51, forming a low dielectric constant substrate 200;

[0054] The low dielectric constant substrate is quartz crystal with a thickness ranging from 100um to 500um.

[0055] Step 52, depositing a low dielectric constant bonding layer 201 on the surface of the low dielectric constant substrate;

[0056] The low dielectric constant bonding layer is a silicon dioxide layer or a benzocyclobutene (BCB) layer with a thickness ranging from 2um to 10um.

[0057] Step 53, removing the low dielectric constant bonding layer below the effective modulation region of the lithium niobate waveguide structure to form a bonding layer 201';

[0058] When the bonding layer is a silicon dioxide layer, dry etching or wet etching is used to remove the low dielectric constant bonding layer below the effectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com