Fuel cell membrane with high tolerance and its preparation method

A fuel cell membrane and tolerance technology, used in fuel cells, fuel cell parts, battery pack parts, etc., can solve the problem of the decrease in the activity of oxygen-containing hydroxyl radicals, the inability to play a protective role, and the acceleration of peroxidation. Hydrogen deterioration and other problems, to achieve the effect of increased tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

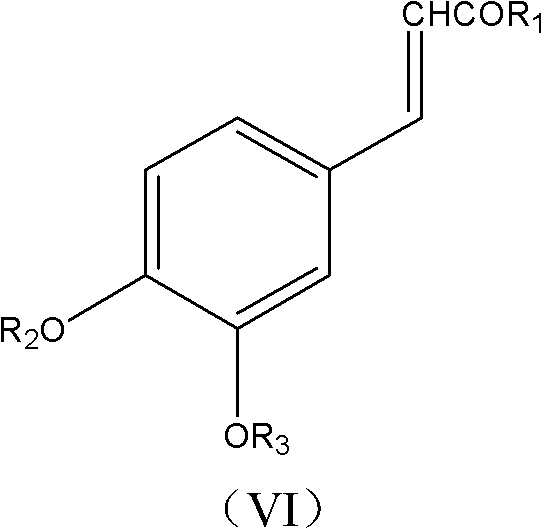

[0050] The exchange capacity obtained by formula (III) and tetrafluoroethylene copolymer hydrolytic acidification is that the perfluorosulfonic acid resin of 1.50mmol / g is dissolved in DMF and forms the dispersion liquid of 25wt%, in this dispersion liquid, add the equivalent to resin weight 8 % of formula (VI) and Ce 3+ The formed complex contains oxygen free radicals to degrade additives, and then disperses evenly, and heats after pouring to volatilize the solvent to obtain a 30-micron-thick high-endurance fuel cell membrane. R in formula (VI) 1 for:

[0051]

[0052] R 2 = H; R 3 =CH 3 .

Embodiment 2

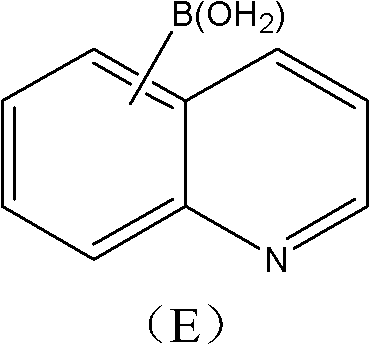

[0054] The perfluorosulfonic acid resin with exchange capacity of 1.25mmol / g obtained by copolymerizing formula (I) with (IV) and tetrafluoroethylene and hydrolytic acidification is dissolved in DMSO to form a 30wt% dispersion liquid. In above-mentioned dispersion liquid, add the formula (E) material that is equivalent to resin weight 15% (the steric hindrance of boronic acid group is in quinoline ring 5) and Mn 2+ The complex oxygen-containing free radical degrading additive that forms; Disperse evenly, the polytetrafluoroethylene microporous membrane (aperture 1 micron) of porosity 95% is immersed in the above-mentioned dispersion liquid, treat the microporous polytetrafluoroethylene membrane After the pores are completely filled, take it out and heat it to volatilize the solvent, and obtain a 20-micron-thick microporous-enhanced high-endurance fuel cell membrane.

Embodiment 3

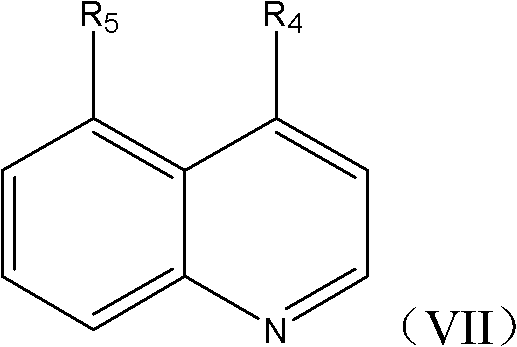

[0056] The exchange capacity obtained by formula (VI) and tetrafluoroethylene copolymerization and acidification hydrolysis is dissolved in propanol-water (propanol: water=1:2 mass ratio) to form 15wt% perfluorophosphoric acid resin Dispersions. Add formula (VII) and La which are equivalent to 3% of resin weight in the above-mentioned dispersion liquid 3+ Formed complex oxygen free radical degradation additive, in formula (VII), R 5 Yes: R 4 Yes: Then disperse evenly, and heat to volatilize the solvent after pouring to obtain a 15 micron thick high-endurance fuel cell membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cation exchange capacity (mol) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com