Plasma ejection device for igniting long air spark gap and circuit thereof

A technology of plasma and spray device, applied in the field of plasma spray device, can solve the problem of non-reusable, etc., and achieve the effects of easy ignition, high working reliability, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

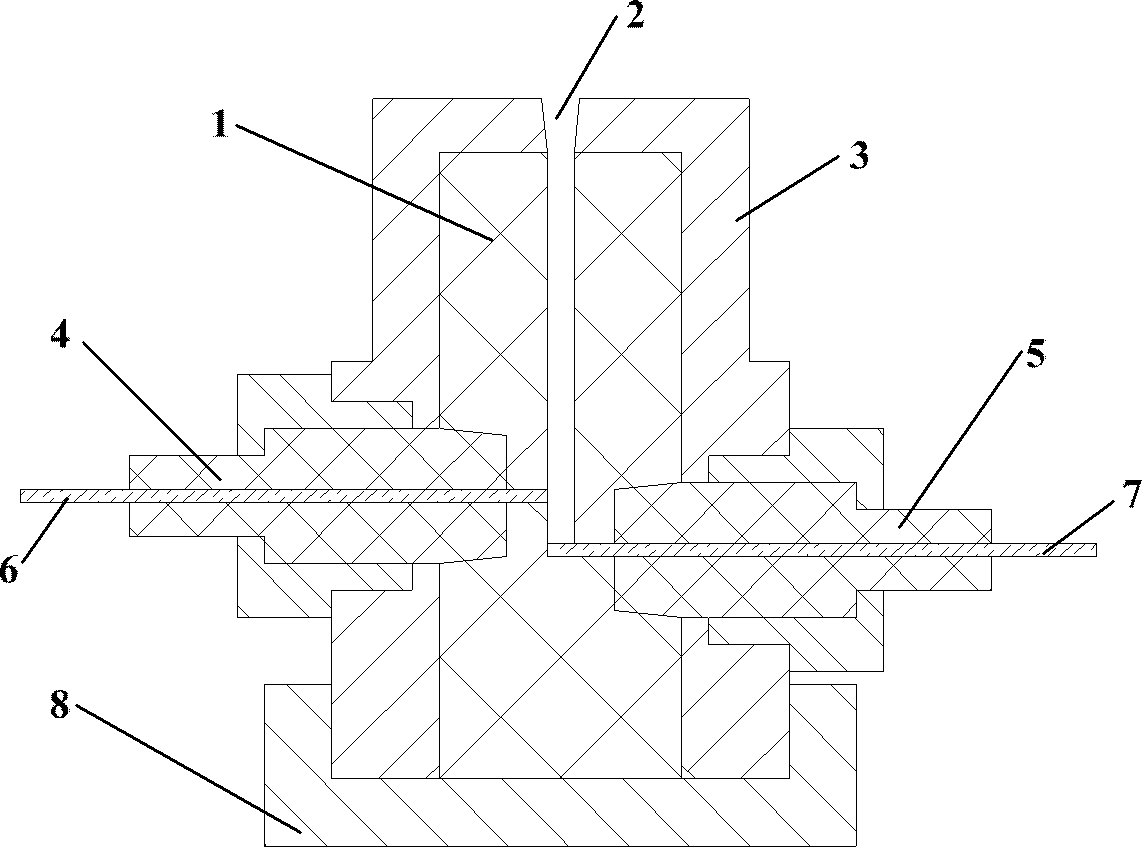

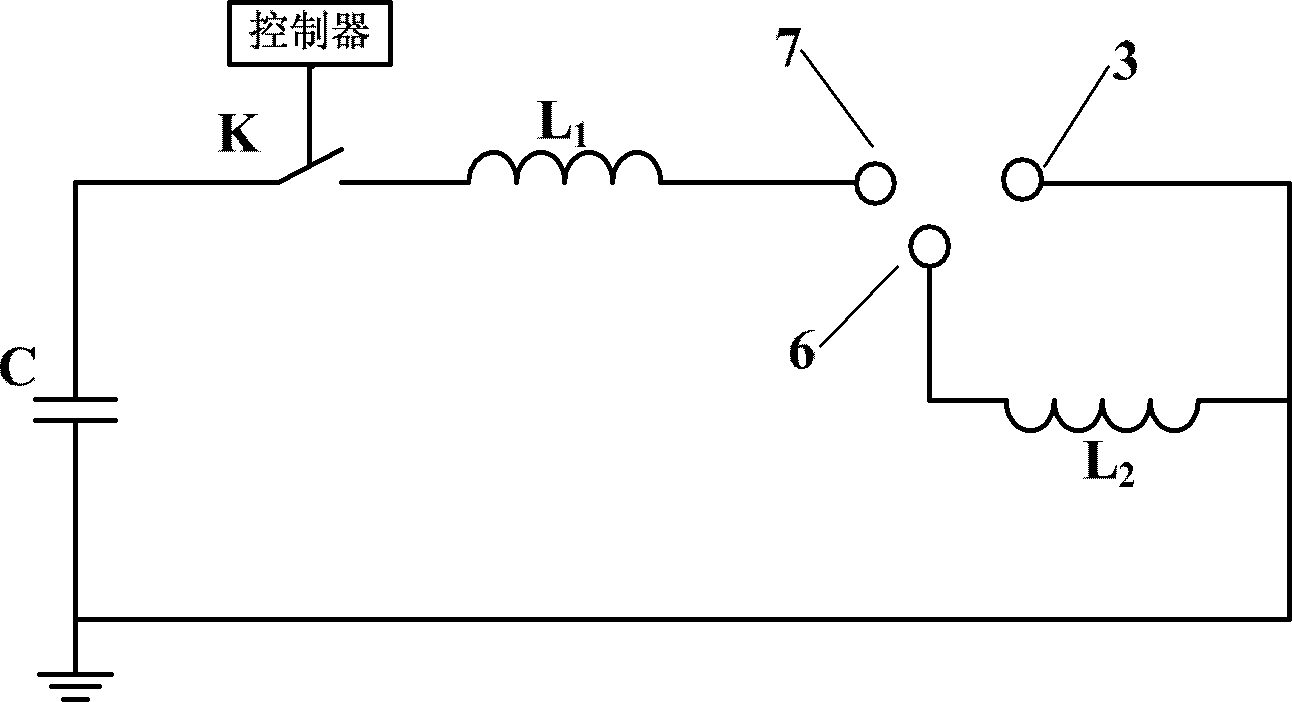

[0034] This embodiment is a plasma injection device for igniting a long air spark gap, and its structural schematic diagram and discharge circuit schematic diagram are as follows figure 2 and image 3 shown. 3 and 8 are metal shells, the gas-generating material 1 is high-density polyethylene, the high-voltage electrode 7 and low-voltage electrode 6 are 1 mm ablation-resistant metal rods, and the insulating sleeves 4 and 5 are made of high-density polyethylene. When using interference fit, each component can achieve a tight fit. The length of the short gap channel is 1mm; the length of the gap channel is 5mm, and the channel diameter is 1mm; the full angle of the nozzle cone angle of the injection device is 8°; the capacity of the discharge capacitor C is 5μF, and the charging voltage is 3kV; the discharge inductance L 2 is 10μH.

Embodiment 2

[0036] This embodiment is a plasma injection device for igniting a long air spark gap, and its structural schematic diagram and discharge circuit schematic diagram are as follows figure 2 and image 3 shown. 3 and 8 are metal shells, the gas-generating material 1 is polycarbonate, the high-voltage electrode 7 and the low-voltage electrode 6 are ablation-resistant metal rods of 2mm, and the insulating sleeves 4 and 5 are made of nylon material, and the over-molding is used during assembly. Surplus assembly, so that each component achieves a tight fit. The length of the short gap channel is 4mm; the length of the gap channel is 30mm, and the channel diameter is 3mm; 2 is 40μH.

Embodiment 3

[0038] This embodiment is a plasma injection device for igniting a long air spark gap, and its structural schematic diagram and discharge circuit schematic diagram are as follows figure 2 and image 3 shown. 3 and 8 are metal shells, the gas-generating material 1 is PMMA, the high-voltage electrode 7 and the low-voltage electrode 6 are 2mm ablation-resistant metal rods, and the insulating sleeves 4 and 5 are made of nylon material, and the interference is used when assembling Assemble so that the various components achieve a tight fit. The length of the short gap channel is 5mm; the length of the gap channel is 50mm, and the channel diameter is 5mm; 2 is 80μH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com