Manufacture method of tissue engineering bracket with both internal microstructure and individualized appearance

A technique for tissue engineering scaffolds and manufacturing methods, applied in medical science, prostheses, etc., can solve problems such as difficult control of process parameters, and achieve the effect of controllable internal microstructure and wide material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

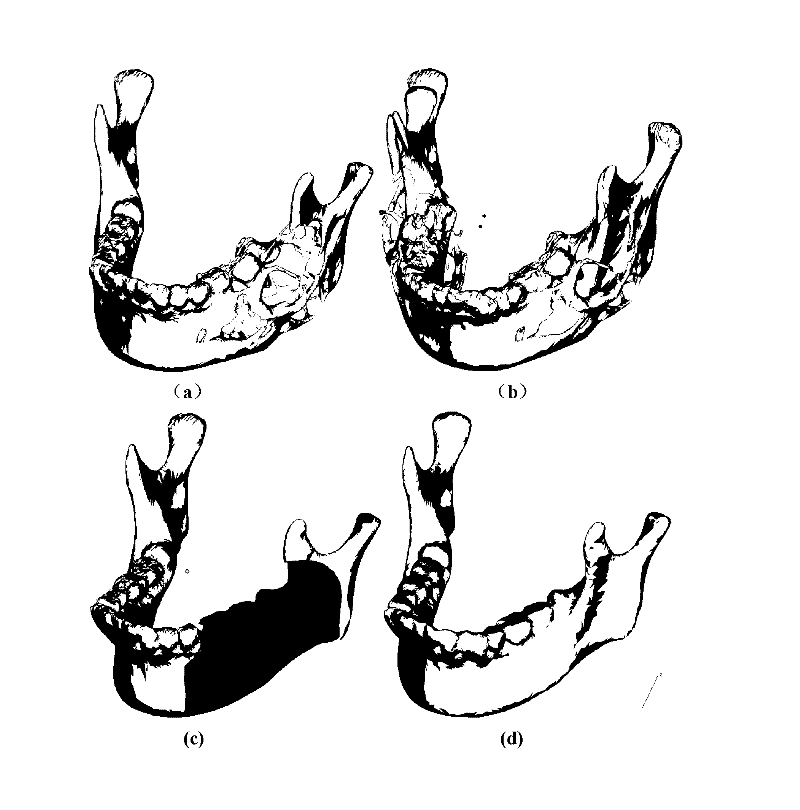

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

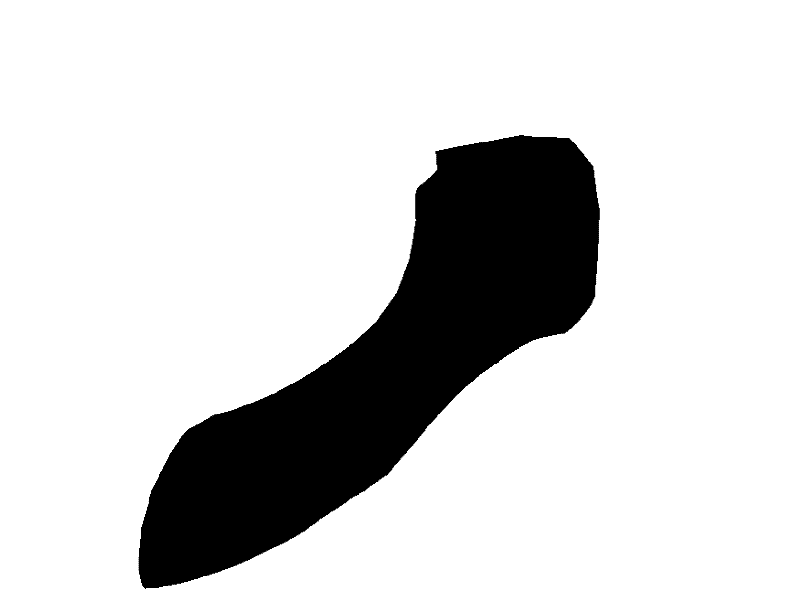

[0024] refer to Figure 1 ~ Figure 4 , a method for manufacturing a tissue engineering scaffold having a controllable internal microstructure and a personalized shape, the manufacturing method comprising the steps of:

[0025] 1) Negative design of the support structure

[0026] 1.1) Design the personalized shape of the stent: First, use the image-based 3D reconstruction technology to reconstruct the 3D model of the bone defect from CT data, and then obtain the repair model through the mirror algorithm or surface design method, and separate the repair model from the repair model. The shape of the defect site is the personalized shape model of the tissue engineering scaffold to be manufactured;

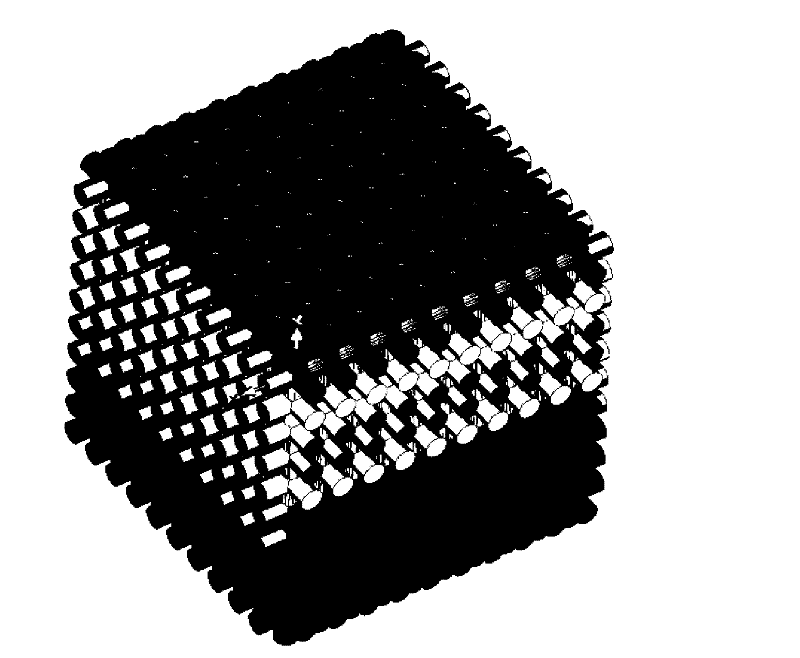

[0027] 1.2) Design porous microstructure: design a scaffold microstructure array with porosity and structural form, and the microstructure is an internal microstructure with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com