Composite catalyst for polyalcohol esterification reaction

A technology of polyol esters and catalysts, which is applied in the field of catalysts for the synthesis of pentaerythritol tetraesters, and can solve the problems of slow reaction speed and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

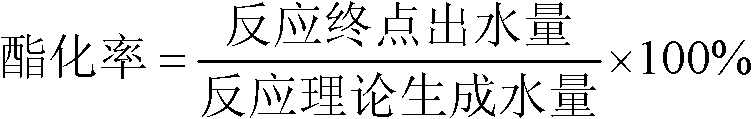

[0018] Add 720 parts by weight of isooctanoic acid and 136 parts by weight of pentaerythritol into a 250ml four-neck flask equipped with a thermometer, agitator, reflux condenser and water separator, stir and heat to 50°C to completely dissolve the alcohol, and add 2.72 parts by weight of the composite catalyst (dodecylbenzenesulfonic acid: hypophosphorous acid in the composite catalyst = 2: 1, mass ratio), heat the system to 160° C., react at constant temperature for 5 hours, and collect the water generated by the reaction at the same time. Cool to room temperature after the reaction, measure the amount of water produced at the end of the reaction, and calculate the esterification rate to be 99.9%.

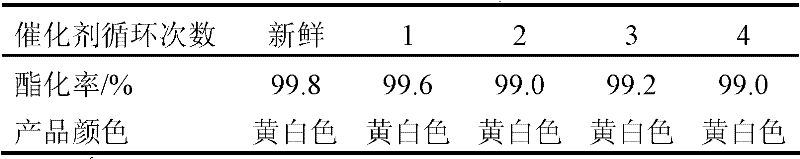

[0019] Post-processing of the product: filter the reaction solution, and the filtered catalyst is washed and dried for recycling. The filtrate was washed 4 times with 100 parts of excess 5% NaOH. The obtained organic phase was washed with water until neutral to obtain a light ye...

Embodiment 2~6

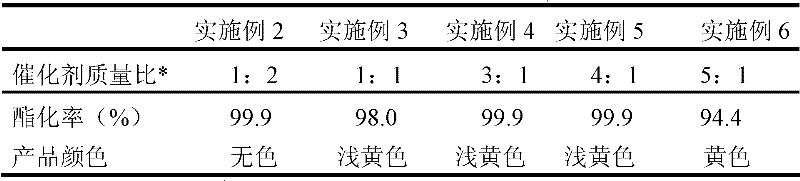

[0021] Press the experimental method of embodiment 1, change the mass ratio of p-toluenesulfonic acid and hypophosphorous acid in composite catalyst, experimental result is as follows:

[0022]

[0023] *The catalyst is p-toluenesulfonic acid: hypophosphorous acid, mass ratio.

Embodiment 7

[0025] According to the experimental method of embodiment 1, use composite catalyst to be p-toluenesulfonic acid: phosphorous acid=2: 1 (mass ratio), the esterification rate obtained is 99.8%, and the color and luster of product is yellow-white.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com