Method for synthesizing mobil composition of matters-41(MCM-41) mesoporous molecular sieve

A technology of MCM-41 and mesoporous molecular sieve, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low synthesis yield of MCM-48, high alkalinity of synthesis system, low utilization rate of silicon source, etc., and achieve economic benefits. and the effect of achieving ecological benefits, reducing synthesis costs, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

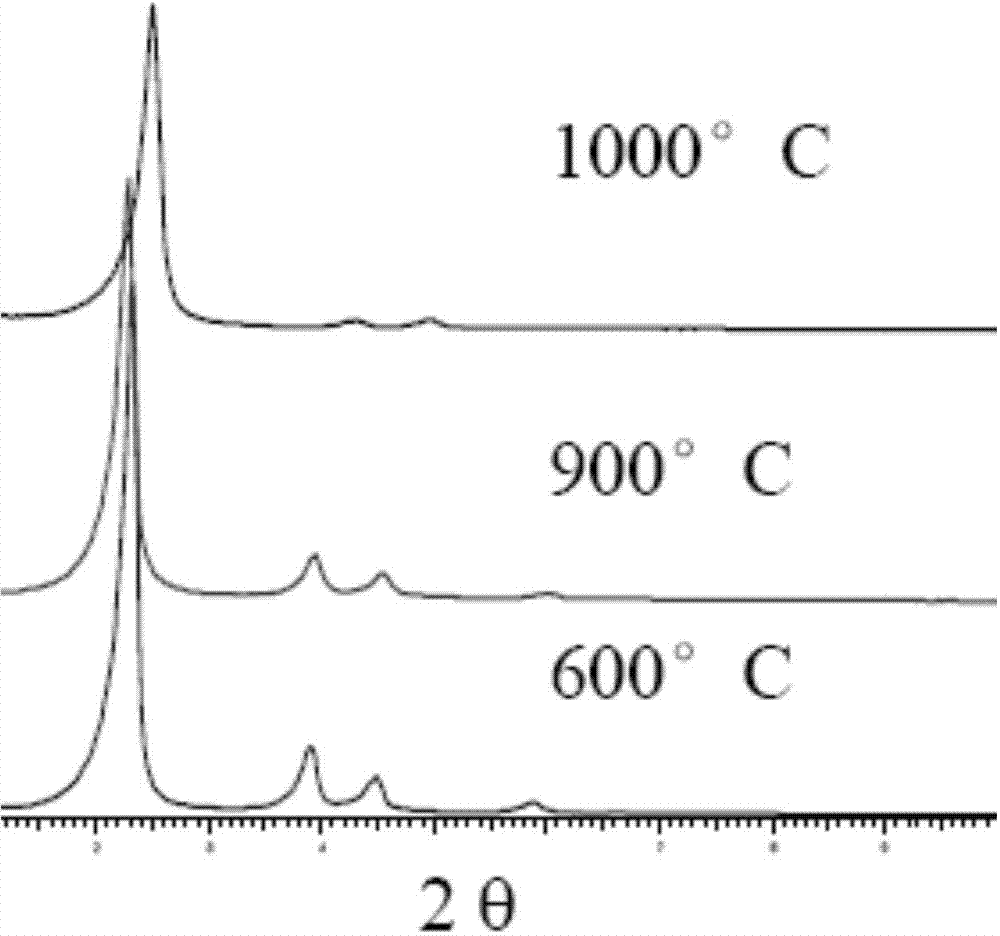

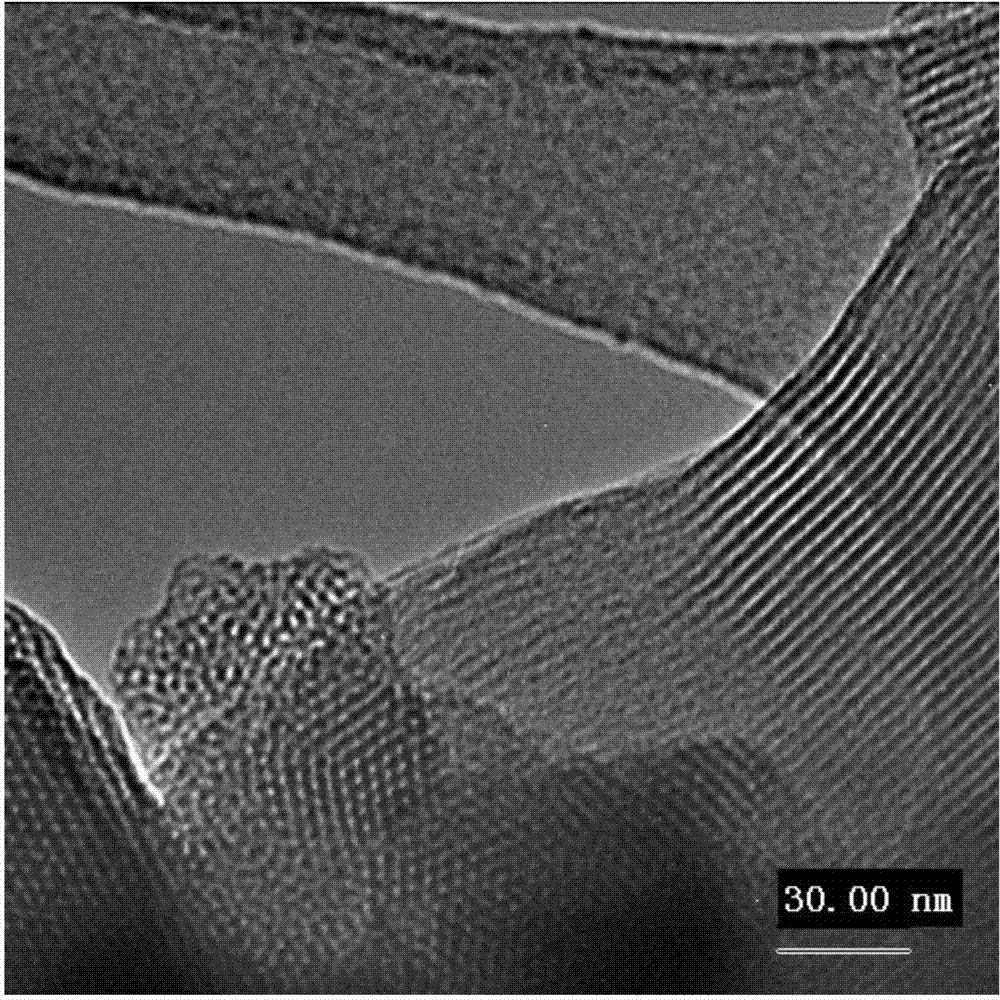

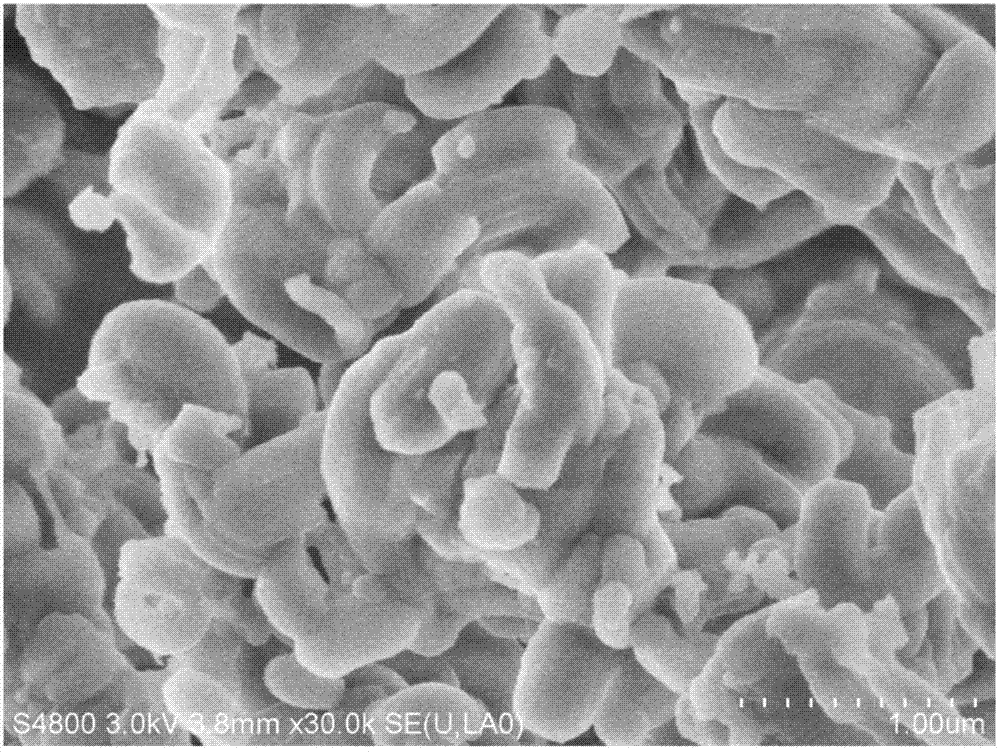

[0018] Preparation of silicon source for the synthesis of MCM-41 mesoporous materials: high-quality MCM-48 mesoporous molecular sieves were synthesized by referring to the method reported in the literature (Micopor. Mesopor. Mater., 2005, 86, 314). Dry to obtain MCM-48 mesoporous molecular sieve. The mother liquor obtained by the first suction filtration is retained, then titrated with 37% concentrated hydrochloric acid to obtain a white precipitate, and the SiO obtained by filtering and washing 2 The filter cake was directly used as the silicon source for the synthesis of MCM-41 mesoporous materials.

[0019] Synthesis of MCM-41 mesoporous material: Add 8.0g NaOH to a beaker containing 720ml deionized water, then add 60.0g SiO obtained by acid titration of MCM-48 mother liquor 2 The filter cake was stirred at a constant temperature of 60°C for 1 hour to obtain solution A; 32.8g of cetyltrimethyl-p-toluenesulfonate (CTATos) was added to a beaker containing 720ml of deionized ...

Embodiment 2

[0022] Potassium hydroxide is used as an alkali source to prepare high-quality MCM-41 mesoporous molecular sieves:

[0023] Except replacing the sodium hydroxide in embodiment 1 with potassium hydroxide, other preparation conditions are all identical with embodiment 1.

Embodiment 3

[0025] Increase the crystallization temperature and prolong the crystallization time to prepare high-quality MCM-41 mesoporous molecular sieves:

[0026] Keeping the molar composition of the mixture SiO 2 / CTATos / NaOH / H 2 O=1:0.05:0.20:80 remains unchanged, the crystallization temperature is 130° C., and the crystallization time is 24 hours. Other preparation conditions and processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com