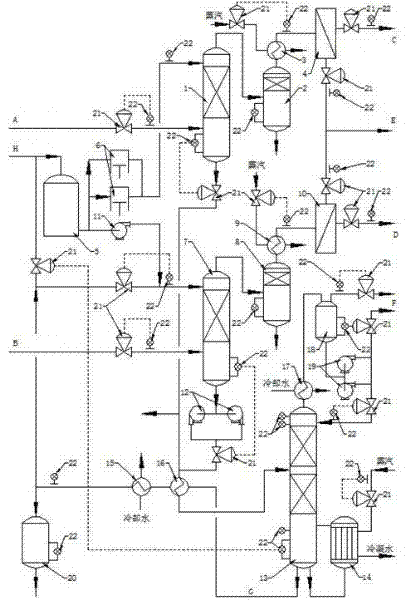

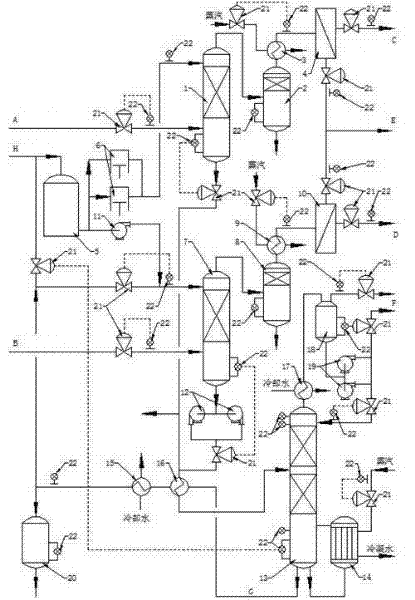

Method for recovering hydrogen and ammonia from synthetic ammonia purge gas by membrane separation-rectification integrated technology and device

A technology of relaxation gas and membrane separation, which is applied in the direction of using solid contact hydrogen separation, hydrogen separation, ammonia preparation/separation, etc., can solve problems such as inability to process ammonia water, uneconomical production of ammonium bicarbonate, and efficient recycling of ammonia and discharge of ammonia water. , to achieve zero emissions, save resources, and solve environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The high-pressure and low-pressure relaxation gases are passed into the high-pressure ammonia absorption tower 1 and the low-pressure ammonia absorption tower 7 respectively, and at the same time, the absorbent is pumped into the high-pressure ammonia absorption tower 1 and the low-pressure ammonia absorption tower 7 through the high-pressure plunger pump 6 and the low-pressure centrifugal water pump 11 respectively. The ammonia in the purge gas is absorbed and treated. During the initial operation of the device, the absorbent is the desalted water sent from outside the device. After the stable operation, the absorbent is the liquid in the rectification tower 13. The ammonia content of the high-pressure relaxation gas after absorption treatment is lower than 200ppm, and the ammonia content of the low-pressure relaxation gas after absorption treatment is lower than 20ppm. The high-pressure and low-pressure relief gases after ammonia removal are respectively fed into the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com