Method for preparing potassium chloride from carnallite containing magnesium sulfate

A technology of carnallite ore and magnesium sulfate, which is applied in the direction of alkali metal chloride, etc., can solve the problems that the product quality and yield of potassium chloride have not reached a reasonable state, suppress sulfate, low grade of potassium chloride, etc., and achieve reduction Operating cost and maintenance cost, increase potassium yield, reduce potassium loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

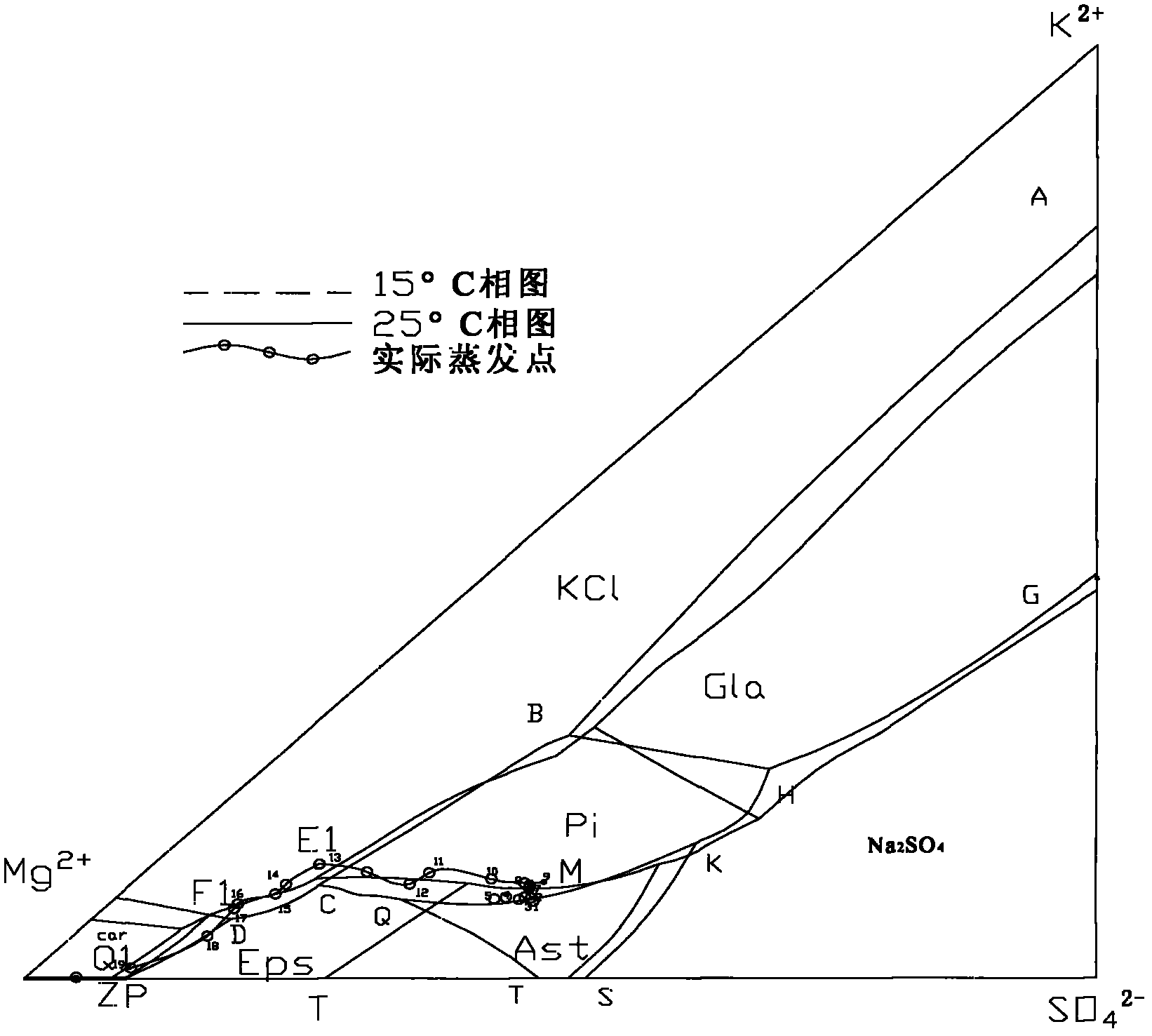

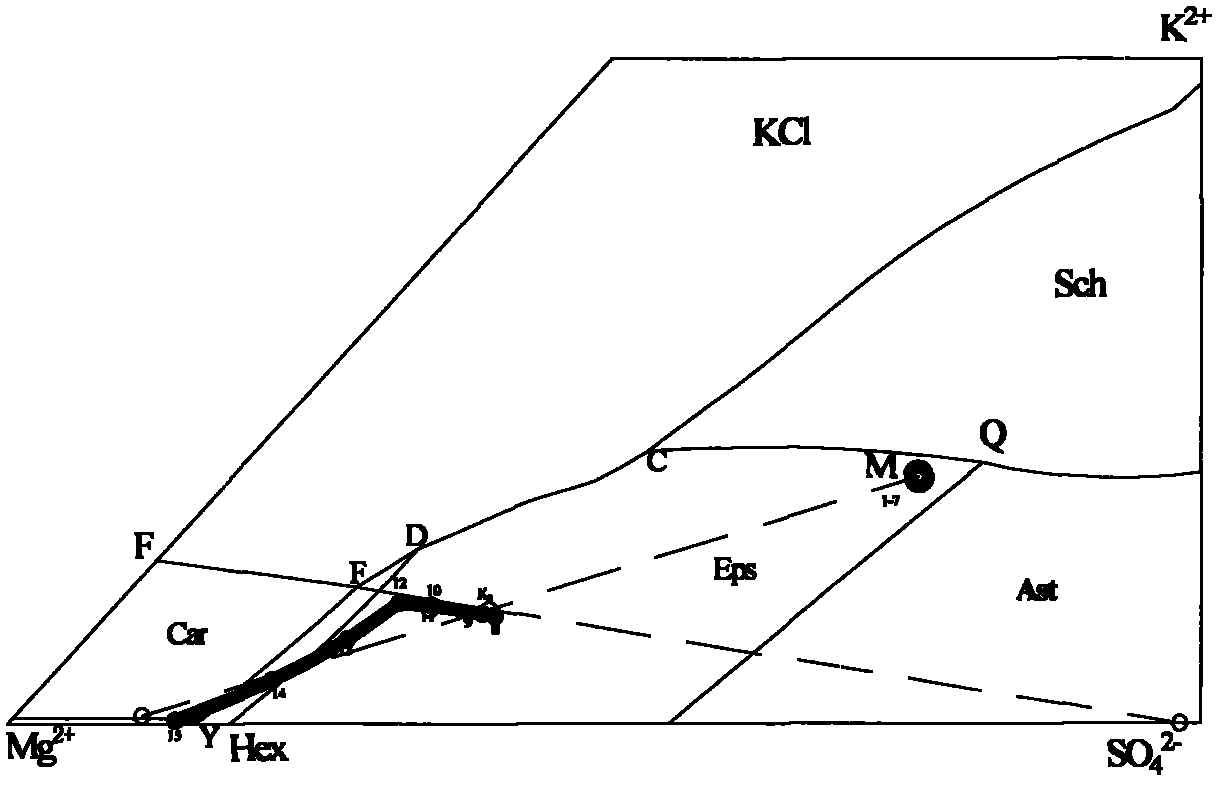

Method used

Image

Examples

Embodiment 1

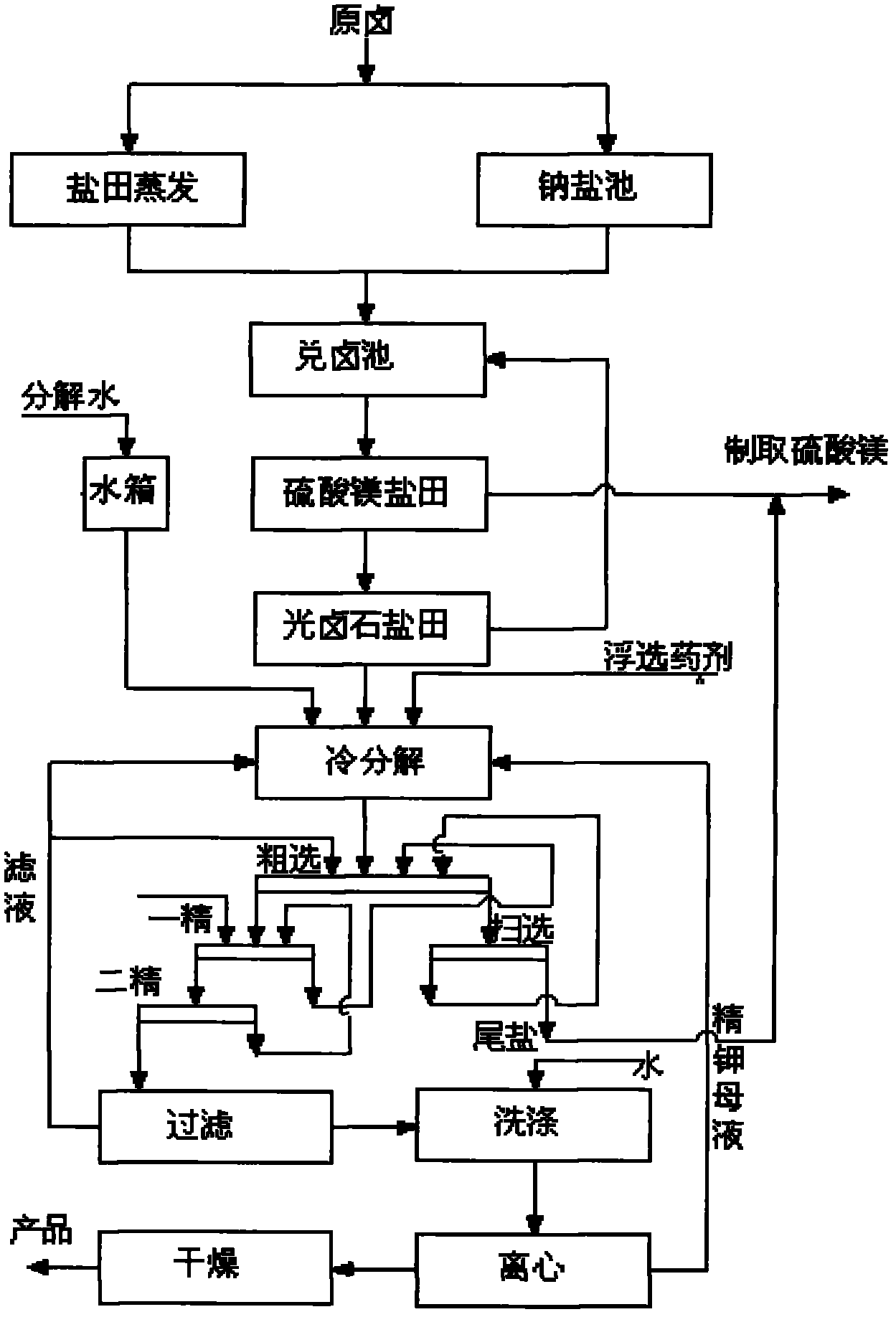

[0033] Embodiment 1 A kind of method that sulfuric acid-containing magnesium carnallite ore produces potassium chloride comprises the following steps:

[0034](1) Divide the original brine into two parts according to the mass ratio (kg / kg) of 1.5:1, one part of which is naturally evaporated to obtain the old brine used in salt field evaporation and sun-drying to prepare brine, and the Mg in the old brine 2+ The mass content is 7.6-8.5%; the other part is naturally evaporated to the sodium salt section, that is, when sodium chloride is precipitated, and the separation liquid is obtained.

[0035] (2) Put the old brine and separation liquid into the brine mixing tank by pump to mix to obtain the mixed liquid phase.

[0036] The volume ratio (L / L) of old brine and separation liquid is 1:1.5.

[0037] (3) The mixed liquid phase separates out magnesium sulfate and sodium chloride through natural evaporation in the magnesium sulfate salt field, and the magnesium sulfate and sodium ...

Embodiment 2

[0045] Embodiment 2 A kind of method that contains magnesium carnallite ore to produce potassium chloride, comprises the following steps:

[0046] (1)~(4) are the same as embodiment 1.

[0047] (5) Add solid phase B—carnallite ore containing magnesium sulfate to 0.4 times its mass into water mixed with flotation agent, decompose at 30°C, add inhibitor after 15 minutes, and mix well The decomposed slurry is obtained; the addition amount of the flotation agent and inhibitor is 1-200ml per ton of carnallite ore containing magnesium sulfate.

[0048] (6)~(9) are the same as embodiment 1.

[0049] (10) Add water to solid phase C by 0.4 times its mass for washing, and obtain a washing slurry after 30 minutes, which is centrifuged to obtain solid phase D and separated liquid phase C respectively; separate liquid phase C and return to the step (5) Decompose; dry the solid phase D at 80°C to constant weight to obtain the potassium chloride product.

Embodiment 3

[0050] Embodiment 3 A kind of method that contains magnesium carnallite ore to produce potassium chloride, comprises the following steps:

[0051] (1)~(4) are the same as embodiment 1.

[0052] (5) Add solid phase B—carnallite ore containing magnesium sulfate 0.3 times its mass into water mixed with flotation agent, decompose at 20°C, add inhibitor after 20 minutes, and mix well to obtain Decompose the slurry; the amount of flotation agent and inhibitor added is 1-200ml per ton of carnallite ore containing magnesium sulfate.

[0053] (6)~(9) are the same as embodiment 1.

[0054] (10) Add water to solid phase C by 0.2 times its mass for washing, and obtain a washing slurry after 20 min, which is centrifuged to obtain solid phase D and separated liquid phase C respectively; separate liquid phase C and return to the step (5) Decompose; dry the solid phase D at 80°C to constant weight to obtain the potassium chloride product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com