Method and device for sludge digestive fluid two-level biological denitrification

A technology of sludge digestion liquid and biological denitrification, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve problems such as inability to remove nitrate nitrogen, limit value denitrification efficiency, etc., and achieve The effect of avoiding inhibition, reducing nitrogen load, and improving denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

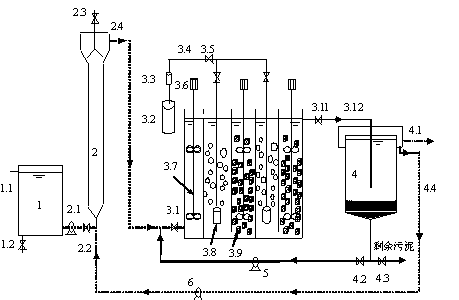

[0032] The specific test water is taken from the digested sludge dehydration liquid of Beijing Gaobeidian Urban Sewage Plant, and its water quality is as follows: COD is 110-250mg / L; NH 4 + -N is 200-400mg / L, NO 2 - -N≤1.5mg / L, NO 3 - -N is below the detection limit, the alkalinity is 1000-1800 mg / L, and the pH is 7.0-7.8. The denitrification reactor is made of plexiglass, the inner diameter of the reaction zone is 8cm, and the effective volume is 8L; the volume of each cell in the autotrophic denitrification reactor is 8L, and the filling ratio of sponge filler in the anoxic biofilm area is 30%.

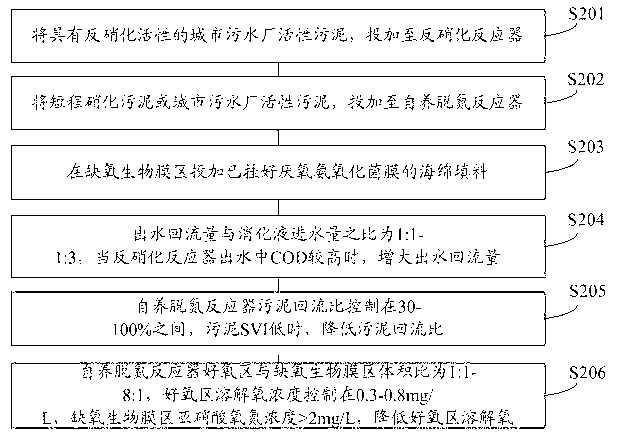

[0033] see figure 2 It is a flow chart of a two-stage biological denitrification method for sludge digested liquid according to the present invention, including:

[0034] S201, adding activated sludge from urban sewage plants with denitrification activity to the denitrification reactor;

[0035] S202, adding short-range nitrification sludge or activated sludge from urban sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com