Antireflective coating solution and preparation method thereof, as well as photovoltaic glass and preparation method of photovoltaic glass

A photovoltaic glass and anti-reflection technology, applied in anti-reflection coatings, optics, optical components, etc., can solve difficult problems such as crystalline silicon power generation efficiency and affecting the power generation efficiency of solar cells, so as to shorten the cost recovery period and improve market value and application prospects, and the effect of enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

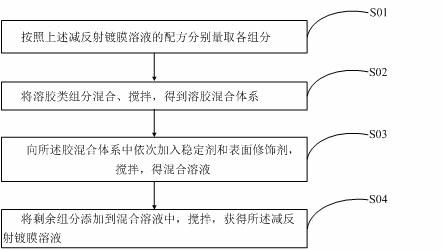

[0036] See figure 1 , Shows a method for preparing an anti-reflection coating solution according to an embodiment of the present invention, which includes the following steps:

[0037] S01: Measure each component according to the formula of the anti-reflection coating solution;

[0038] S02: mixing and stirring the sol components to obtain a sol mixed system;

[0039] S03: Add a stabilizer and a surface modifier to the sol mixing system in sequence, and stir to obtain a mixed solution;

[0040] S04: Add the remaining components to the mixed solution and stir to obtain the anti-reflection coating solution.

[0041] In step S01, each component can be purchased commercially or can be obtained by an existing preparation method, and each component is accurately measured for use.

[0042] In step S02, the sol component includes silica sol, titania sol, zirconia sol, and ceria and / or magnesium oxide and / or alumina sol. All sol components are stirred uniformly to obtain a sol mixed system.

[0...

Embodiment 1

[0053] The preparation method of the high transmittance photovoltaic glass roll coating solution of this embodiment includes the following steps:

[0054] Step one: preparing silica sol, titania sol, alumina sol, and zirconia sol;

[0055] Step two, adding titania, alumina sol, and zirconia sol to silica sol in sequence, and stirring uniformly to obtain solution A;

[0056] Step 3: Add a stabilizer and a surface modifier to the system of Step 2 in sequence, and stir for 30 minutes at a stirring speed of 200 rpm to obtain solution B;

[0057] Step 4: In the solution B obtained in step 3, add a volatilization control agent, a leveling agent, etc., and stir for 20 minutes to obtain a roll coating coating liquid.

[0058] Among them, the silica sol in step 1 is a sol with a particle size of 10 to 80 nm obtained by acid catalysis or alkali catalysis or acid-base catalysis; the titanium dioxide sol is an acid catalyzed or alkali catalyzed sol with a particle size of 5-30 nm; Alumina sol is a...

Embodiment 2

[0064] The preparation method of the high transmittance photovoltaic glass roll coating solution of this embodiment includes the following steps:

[0065] Step one: preparing silica sol, titania sol, and zirconia sol;

[0066] Step two, adding titania and zirconia sol to the silica sol in sequence, and stirring uniformly to obtain solution A;

[0067] Step 3: Add a stabilizer and a surface modifier to the system of Step 2 in sequence, and stir for 15 minutes at a stirring speed of 300 rpm to obtain solution B;

[0068] Step 4: In the solution B obtained in step 3, add a volatilization control agent, a roll coating film regulator, and a leveling agent, and stir for 30 minutes to obtain a roll coating film solution.

[0069] Among them, the silica sol in step one is a sol with a particle size of 15-40 nm obtained by acid catalysis or alkali catalysis or two-step acid-base catalysis; the titanium dioxide sol is an acid-catalyzed or alkali-catalyzed sol with a particle size of 5-25 nm; Zir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com