Aluminum nitrogen demanganization swing spout castable

A technology of swing nozzle and castable, applied in the field of refractory materials, can solve the problems of increased labor intensity, decreased life of swing nozzle, affecting the turnaround time of iron mouth and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

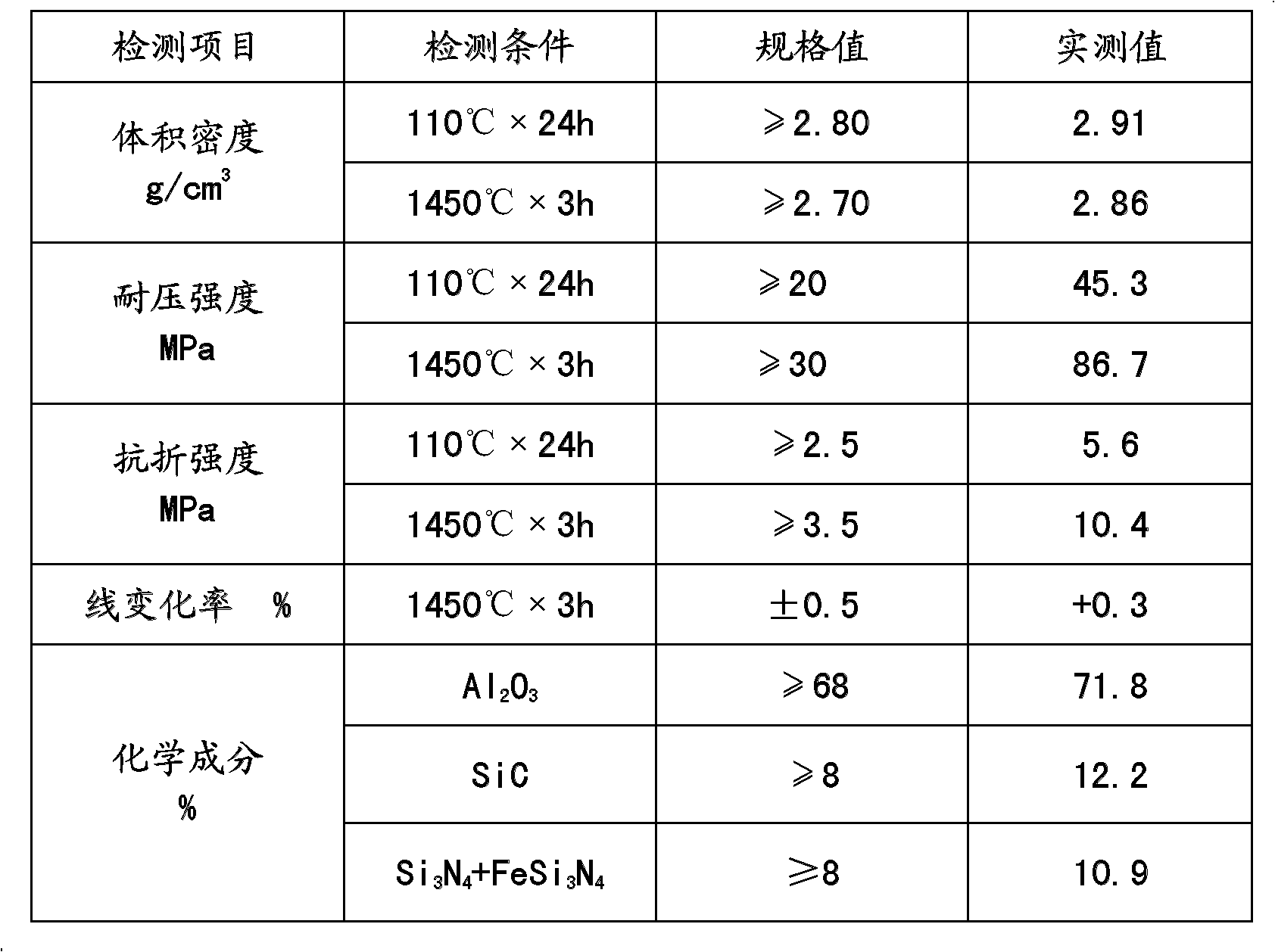

Examples

Embodiment 1

[0020] Example 1, fused dense corundum 5-8mm: 14%; brown corundum 3-5mm: 22%; tabular corundum 1-3mm: 18%; activated alumina powder <3um: 11%; silicon carbide 1-3mm: 8%; silicon carbide 45um: 3%; spherical pitch: 5%; silicon nitride: 7%; ferrosilicon nitride: 5%; metal powder: 1%; sodium hexametaphosphate: 0.6%; %; explosion-proof agent: 3%; silicon powder: 2%.

Embodiment 2

[0021] Example 2, fused dense corundum 5-8mm: 12%; brown corundum 3-5mm: 22%; tabular corundum 1-3mm: 18%; activated alumina powder <3um: 13%; silicon carbide 1-3mm: 5%; silicon carbide 45um: 6%; spherical pitch: 5%; silicon nitride: 7%; ferrosilicon nitride: 5%; metal powder: 1%; sodium hexametaphosphate: 0.6%; %; explosion-proof agent: 2.5%; silicon powder: 2.5%.

Embodiment 3

[0022] Example 3, fused dense corundum 5-8mm: 15%; brown corundum 3-5mm: 19%; tabular corundum 1-3mm: 17%; activated alumina powder <3um: 10%; silicon carbide 1-3mm: 8%; silicon carbide 45um: 6%; spherical pitch: 5%; silicon nitride: 6.5%; ferrosilicon nitride: 4%; metal powder: 1%; sodium hexametaphosphate: 0.8%; %; explosion-proof agent: 4%; silicon powder: 3%.

[0023] The invention selects composite corundum aggregate and high-quality SiC to improve the thermal shock resistance stability and erosion resistance of the pouring material. In order to prevent SiC from being oxidized, Al 2 o 3 -Add Si to SiC-C castable 3 N 4 (silicon nitride), Si, and Al 2 o 3 The SiAlON (Sialon) matrix binding form generated by the in situ reaction improves the solid-solid direct binding rate of the matrix; adding FeSi 3 N 4 (ferrosilicon nitride), high temperature forms a melt covering the surface of the material to prevent silicon carbide and carbon from being oxidized. Add non-metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com