Catalyst composition for preparing 1,2-polybutadiene, and preparation method for 1,2-polybutadiene

A polybutadiene and catalyst technology, applied in the field of polymers, can solve problems such as unfavorable industrial production, reduced catalytic activity, complex components, etc., achieve strong thermodynamic stability and chemical stability, improve catalytic activity, and use less Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a kind of preparation method of 1,2-polybutadiene, comprises the following steps:

[0053] Under the action of the obtained catalyst composition for preparing 1,2-polybutadiene, 1,3-butadiene is polymerized in an organic solvent to obtain 1,2-polybutadiene.

[0054] The present invention is preferably under the protection of nitrogen, preferably adding 1,3-butadiene, an organic solvent and the catalyst composition for preparing 1,2-polybutadiene to an anhydrous and oxygen-free polymerizer to carry out the polymerization reaction, Then it is preferred to terminate the reaction with an ethanol solution of 1% 2,6-di-tert-butyl-p-cresol with a mass fraction, preferably to precipitate the polymer with ethanol, and preferably after washing with ethanol, extruding, and preferably vacuum-drying to constant Weight, to obtain polybutadiene product.

[0055] Wherein, the present invention uses the obtained catalyst composition for the preparati...

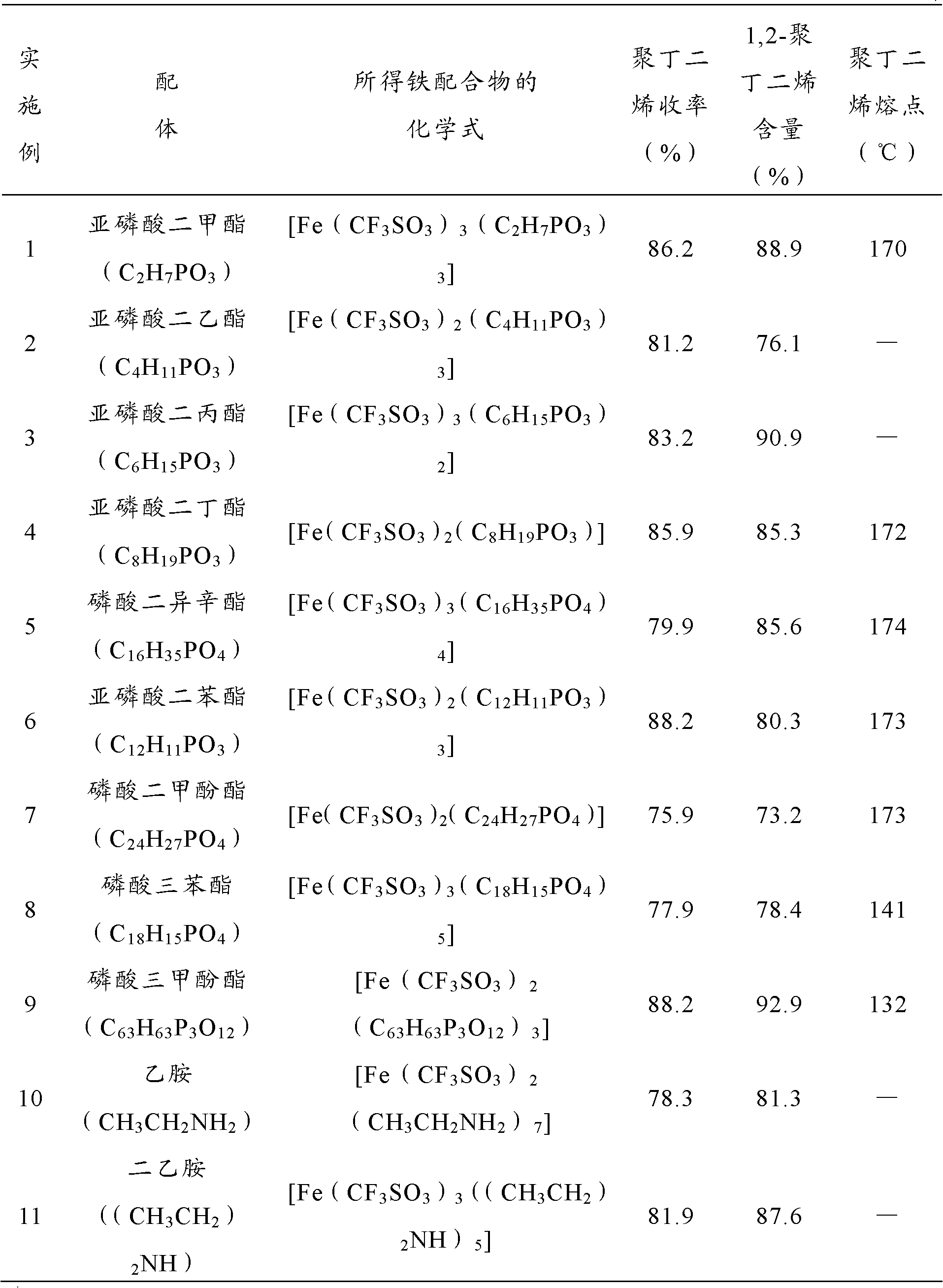

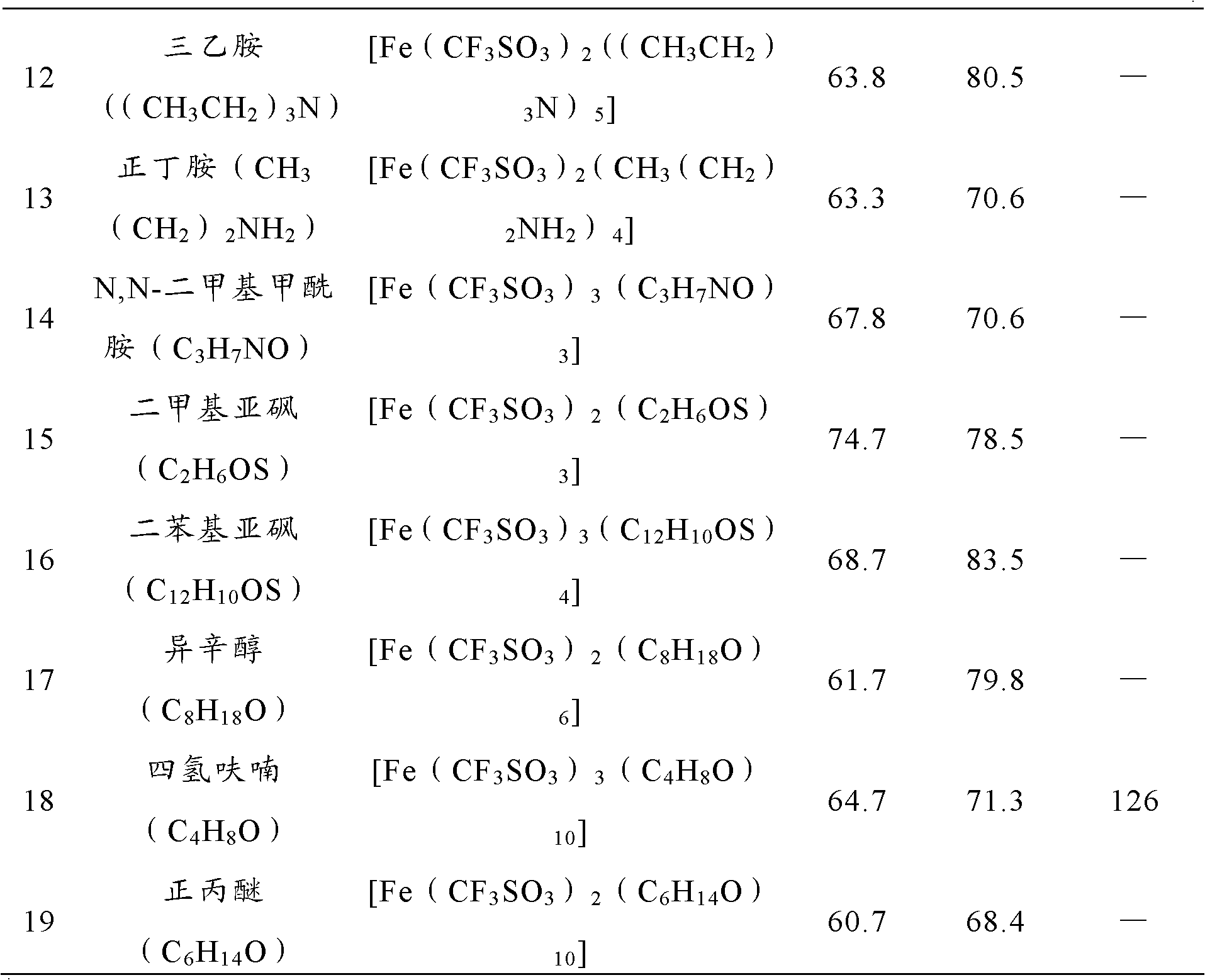

Embodiment 1

[0062] Under nitrogen protection, iron and dimethyl phosphite (C 2 h 7 PO 3 ) in a molar ratio of 1:3, iron trifluoromethanesulfonate and dimethyl phosphite were added to the reactor, and 40 mL of tetrahydrofuran was added as a solvent to obtain a mixed solution, and then the mixed solution was condensed and refluxed in a boiling state for 24 hours After evaporating the solvent, and drying to constant weight, the chemical formula is [Fe(CF 3 SO 3 ) 3 (C 2 h 7 PO 3 ) 3 ] of iron complexes.

[0063] Under the protection of nitrogen, 4×10 -5 mol obtained iron complex, 1.6mL hexane and 0.4mL Al(i-Bu) with a concentration of 2.0mol / L 3 hexane solution to obtain a concentration of 2 x 10 -5 mol / mL is used to prepare the catalyst composition of 1,2-polybutadiene, wherein, Al(i-Bu) 3 The molar ratio of iron in the obtained iron complex is 20:1.

[0064] Under the protection of nitrogen, add 20mL concentration of 20g / 100mL 1,3-butadiene hexane solution to an anhydrous and ...

Embodiment 2

[0067] Under nitrogen protection, iron and diethyl phosphite (C 4 h 11 PO 3 ) in a mol ratio of 1:3, ferrous trifluoromethanesulfonate and diethyl phosphite were added to the reactor, and then 40mL of tetrahydrofuran was added as a solvent to obtain a mixed solution, then the mixed solution was condensed and refluxed in a boiling state, After 24h, the solvent was evaporated and dried to constant weight to obtain the chemical formula [Fe(CF 3 SO 3 ) 2 (C 4 h 11 PO 3 ) 3 ] of iron complexes.

[0068] Under the protection of nitrogen, 4×10 -5 mol obtained iron complex, 0.4mL 1,3-butadiene hexane solution with a concentration of 1.0mol / L, 1.5mL hexane and 0.1mL Al(i-Bu) with a concentration of 2.0mol / L 2 H in hexane to obtain a concentration of 2 x 10 -5mol / mL is used to prepare the catalyst composition of 1,2-polybutadiene, wherein, the mol ratio of 1,3-butadiene and iron in the obtained iron complex is 10:1, Al(i-Bu) 2 The molar ratio of H to iron in the obtained iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com