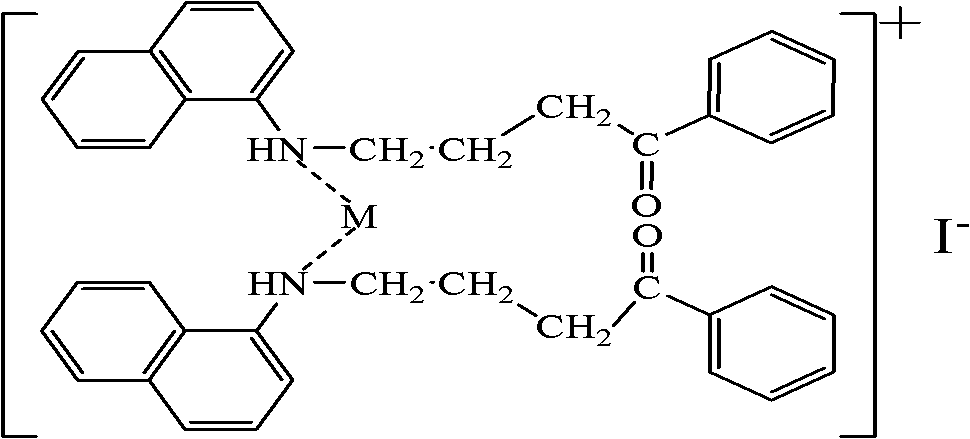

Mannich base metal iodide corrosion inhibitor and preparation method thereof

A metal iodide, Mannich base technology, applied in chemical instruments and methods, potassium organic compounds, copper organic compounds, etc., can solve problems such as strong acid corrosion, and achieve the effect of solving easy decomposition and satisfying protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

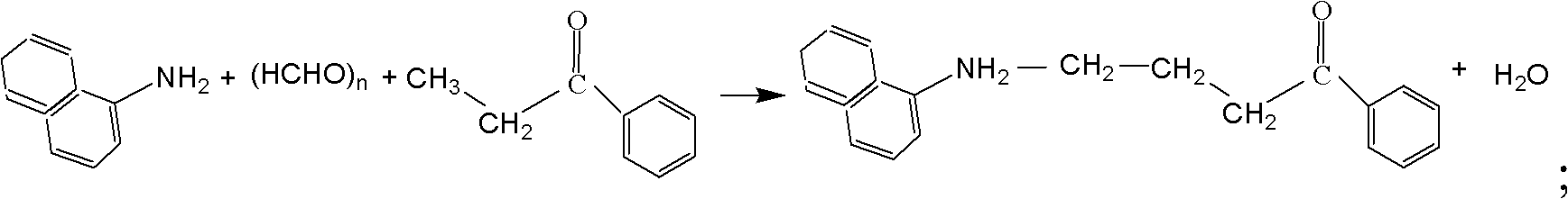

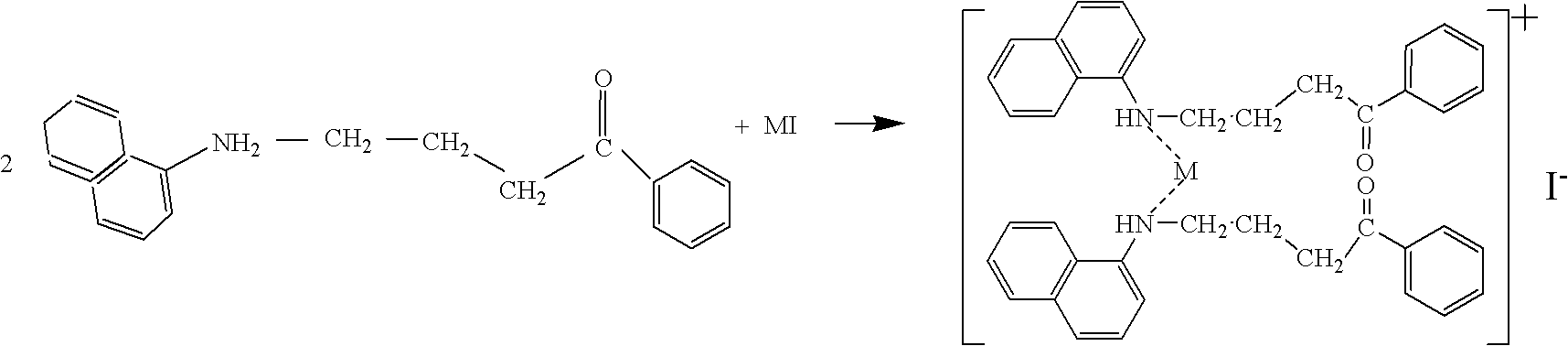

Embodiment 1

[0027] Add 1-naphthylamine, paraformaldehyde, and propiophenone into a three-necked flask at a molar ratio of 1:1.5:1, then add toluene (wherein the molar ratio of toluene to 1-naphthylamine is 4:1) and mix well, and Hydrochloric acid with a percentage of 30% is used as a catalyst to adjust the pH value of the solution to 2.0, then heat up to toluene reflux temperature of 110° C., and keep the temperature for 5 hours to obtain the aldehyde, ketone and amine condensate; add 50% of the total weight of the aldehyde, ketone and amine condensate. Copper, stir evenly and heat up to 50 DEG C, react for 2 hours to obtain Mannich base iodide; then the mass percentages are respectively 30% Mannich base iodide, 10% cetylpyridinium chloride, 10% nonylphenol polyoxyethylene ether and 50% methanol are mixed and stirred evenly.

Embodiment 2

[0029] Add 2-naphthylamine, paraformaldehyde, and propiophenone into a three-necked flask at a molar ratio of 1:1.5:1, then add toluene (wherein the molar ratio of toluene and 1-naphthylamine is 4:1) and mix well, and Hydrochloric acid with a percentage of 30% is used as a catalyst to adjust the pH value of the solution to 2.0, then heat up to toluene reflux temperature of 110° C., and keep the temperature for 5 hours to obtain the aldehyde, ketone and amine condensate; add 50% of the total weight of the aldehyde, ketone and amine condensate. Copper, stir evenly and heat up to 50°C, react for 1 hour to obtain Mannich base iodide; then the mass percentages are respectively 20% Mannich base iodide, 11.5% cetylpyridinium chloride, 8.5% nonylphenol polyoxyethylene ether, 20% isopropanol, and 40% methanol can be mixed and stirred evenly.

Embodiment 3

[0031] Add 1-naphthylamine, paraformaldehyde, and propiophenone into a three-necked flask at a molar ratio of 1:1.5:1, then add toluene (wherein the molar ratio of toluene to 1-naphthylamine is 4:1) and mix well, and Hydrochloric acid with a percentage of 30% is used as a catalyst to adjust the pH value of the solution to 3.0, then heat up to the reflux temperature of toluene at 110° C., and keep the temperature for 5 hours to obtain the aldehyde, ketone, and amine condensate; Homogenize and heat up to 50°C, and react for 2 hours to obtain Mannich base iodide; then the mass percentages are 15% Mannich base iodide, 10% cetylpyridinium chloride, 5% nonyl Base phenol polyoxyethylene ether, 60% ethanol and mix and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com