Preparation method of recombinant carboxypeptidase B

A technology of carboxypeptidase and enzyme cleavage site, which is applied in the field of preparation of recombinant carboxypeptidase B, and can solve problems such as the risk of pharmaceutical proteins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

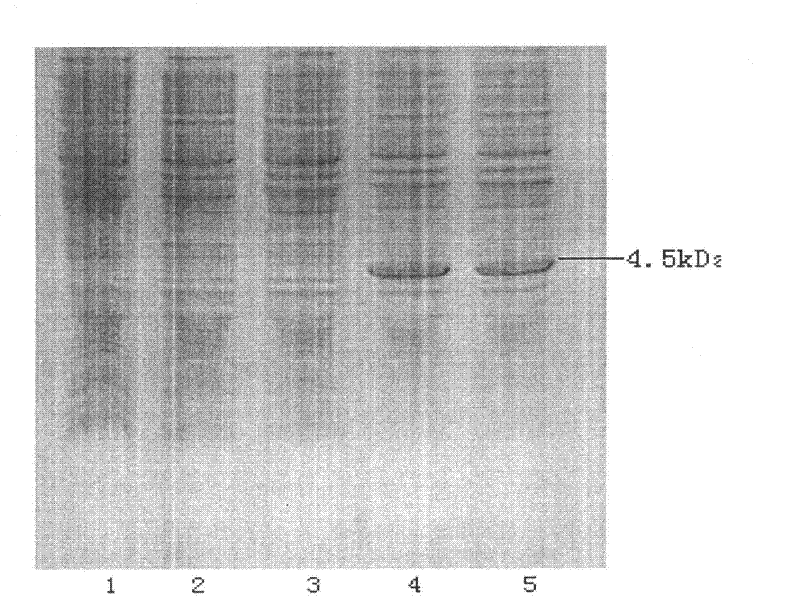

[0053] Example 3 Carboxypeptidase B Purification

[0054] After the fermentation, the cells were collected by centrifugation, and the crushing buffer (25mmol / L Tis-HCL+5mmol / L EDTA, pH7.5) was added at a weight-to-volume ratio of 1:10. The inclusion body precipitate was collected, and the weight loss of the inclusion body was 30g / L fermentation broth. Add the precipitate to washing buffer (2 mol / L urea + 1.5% Triton) at a weight-to-volume ratio of 1:10, stir magnetically at room temperature for 1 hour, and wash the precipitate collected by centrifugation twice with washing buffer. The inclusion body was then dissolved overnight with inclusion body dissolution buffer (8mol / L urea+10mmol / LEDTA+25mmol / L Tis-HCL, pH7.5) at a weight-to-volume ratio of 1:10. The dissolved inclusion bodies were centrifuged and ultrafiltered to remove impurities (such as Figure 4 shown), diluted to a protein concentration of 0.2mg / ml, in refolding buffer (0.2mol / L urea+10mmol / LEDTA+25mmol / L Tis-HCL...

example 4

[0055] The activity measurement of example 4 carboxypeptidase

[0056] The activity of carboxypeptidase B was determined by hydrolyzing hippuronyl-L-arginine at 25°C and pH 7.65,

[0057] Buffer: 25 mM Tris HCl buffer containing 100 mM NaCl at 25°C, pH 7.65.

[0058] Substrate solution: 1.0 mM hippurinyl-L-arginine solution.

[0059] Carboxypeptidase B enzyme solution: (prepared when used, containing 4-8 enzyme activity units / ml water)

[0060] Record the increase in absorption value within 5 minutes ( Figure 6 ), the maximum absorbance / time is obtained using the maximum linear velocity of the assay and blank.

[0061]

[0062] df: dilution factor

[0063] It was determined that the purified recombinant carboxypeptidase B had an activity of 98 units per milligram.

[0064]

[0065]

[0066]

[0067]

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com