Slag modifier and preparation method and application thereof

A modifier and slag technology, applied in the field of steelmaking and refining, can solve the problems of increasing the cost of steelmaking, high cost, affecting refining efficiency, etc., and achieve the effects of saving resources, hard texture, and outstanding economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

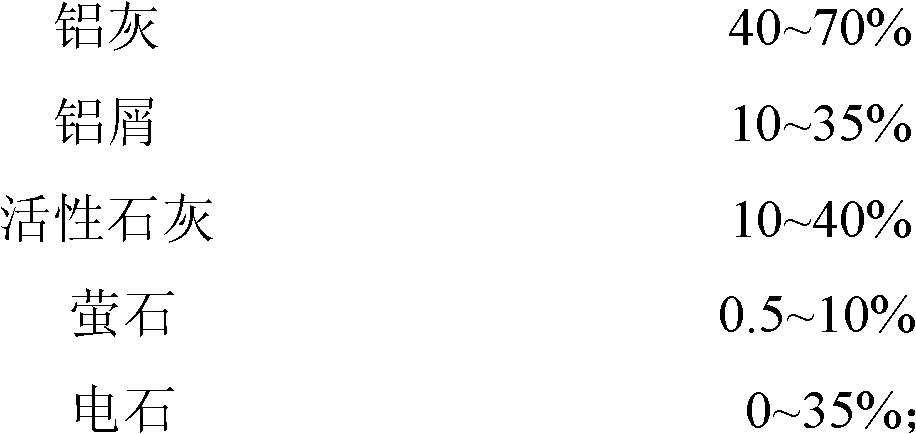

[0023] ①Weigh 60 parts by mass of aluminum ash with an Al content of 45%, 10 parts by mass of aluminum scraps with an Al content of 89%, 25 parts by mass of active lime with a CaO content of 89%, and CaF 2 5 parts by mass of fluorite with a content of 80%, mixed in a closed pre-mixing equipment;

[0024] ②It is mechanically formed under the pressure of 35MPa, and it is a sphere-like body of ∮15~∮40.

[0025] The detected component content is SiO 2 : 5.6%, CaO: 26.5%, Al: 35.5%, Al 2 O 3 : 28.9%, MgO: 2.1%, trace impurities.

Embodiment 2

[0027] The slag modifier obtained in Example 1 was tested in the following process: converter tapping-ladle blowing argon-adding slag modifier-RH process, and added to the surface of molten steel in an amount of 1-2Kg / t. The average content of (FeO+MnO) in the slag before RH treatment reached 9.58%, and the average removal rate of FeO content in the converter residue reached 69.98%.

Embodiment 3

[0029] ①Weigh 50 parts by mass of aluminum ash with an Al content of 48%, 20 parts by mass of aluminum scraps with an Al content of 85%, 12 parts by mass of active lime with a CaO content of 88%, and CaF 2 8 parts by mass and CaC with a content of 85% 2 10 parts by mass of calcium carbide with a content of 75% are mixed in a closed pre-mixing device;

[0030] ②It is mechanically formed under the pressure of 35MPa, and it is a sphere-like body of ∮15~∮40.

[0031] The detected component content is SiO 2 : 3.5%, CaO: 22%, Al: 41%, Al 2 O 3 : 26.3%, MgO: 2.4%, CaF 2 : 4.2%, trace impurities.

[0032] The slag modifier was added to molten steel in 23 furnaces for testing, and the average content of (FeO+MnO) in the slag reached 7.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com