Czochralski zone melting gas doping method for preparing zone-melted silicon single crystal

A technology of Czochralski zone melting and zone melting silicon, which is applied in self-zone melting method, single crystal growth, crystal growth, etc., can solve the large difference between the center resistivity and edge resistivity of silicon wafers, and reduce the diameter of zone melting silicon single crystal Problems such as the uniformity of resistivity and the inability to be effectively controlled can achieve the effects of high uniformity, uniform dopant concentration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

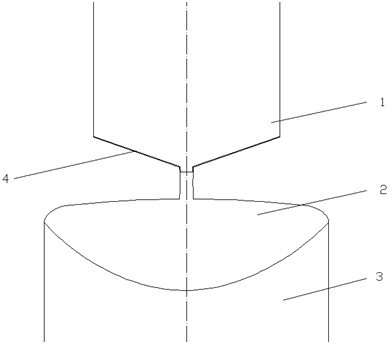

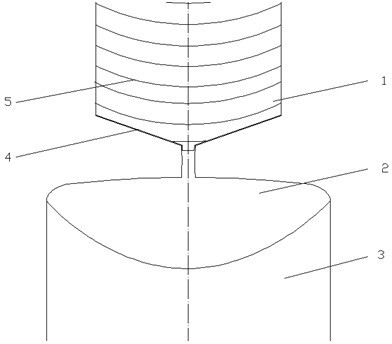

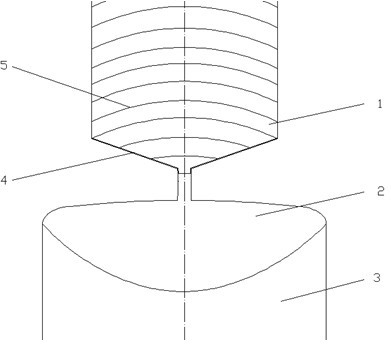

[0023] Such as Figure 1 to Figure 4 As shown in Fig. 1, silicon polycrystalline rods are pulled by the Czochralski method, and the doping is completed before pulling the crystal, and the tail dopant concentration is controlled to c0.

[0024] After the polycrystalline rod is rolled, grooved, sharpened and other machined, it is annealed to eliminate its thermal stress and mechanical processing stress.

[0025] Place the polysilicon rods in the zone furnace, preheat, melt, and start crystal pulling.

[0026] After seeding and thinning the neck, reduce the speed of the lower shaft and the rotational speed of the lower shaft to start expanding the shoulder. During the process of expanding the shoulder, the dopant gas is introduced to make the dopant concentration in the silicon melt c0 / k. The measurement of the axial resistivity of the crystal rod can be used to distribute the dopant concentration in the axial direction, and adjust the amount of dopant gas introduced, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com