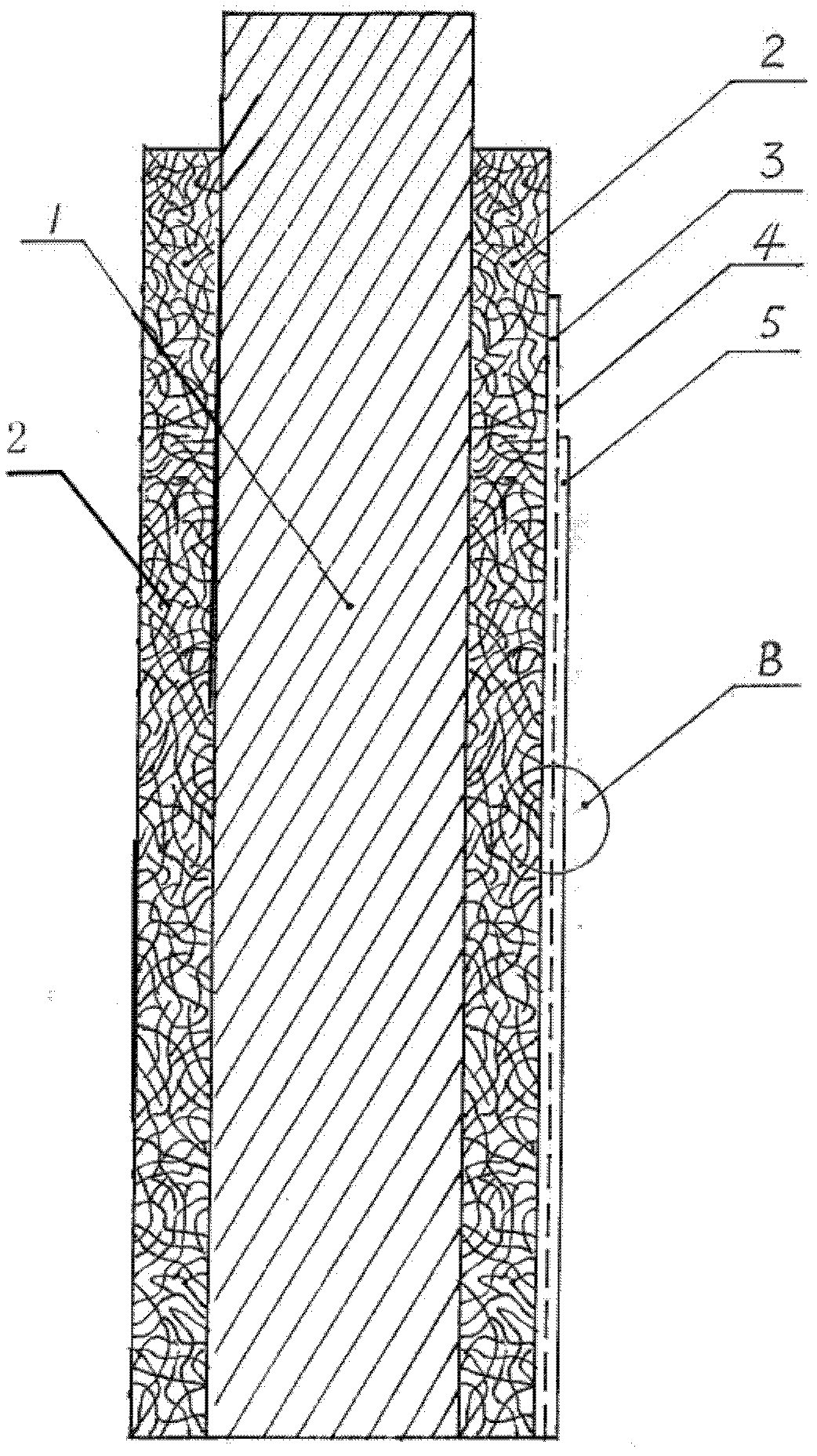

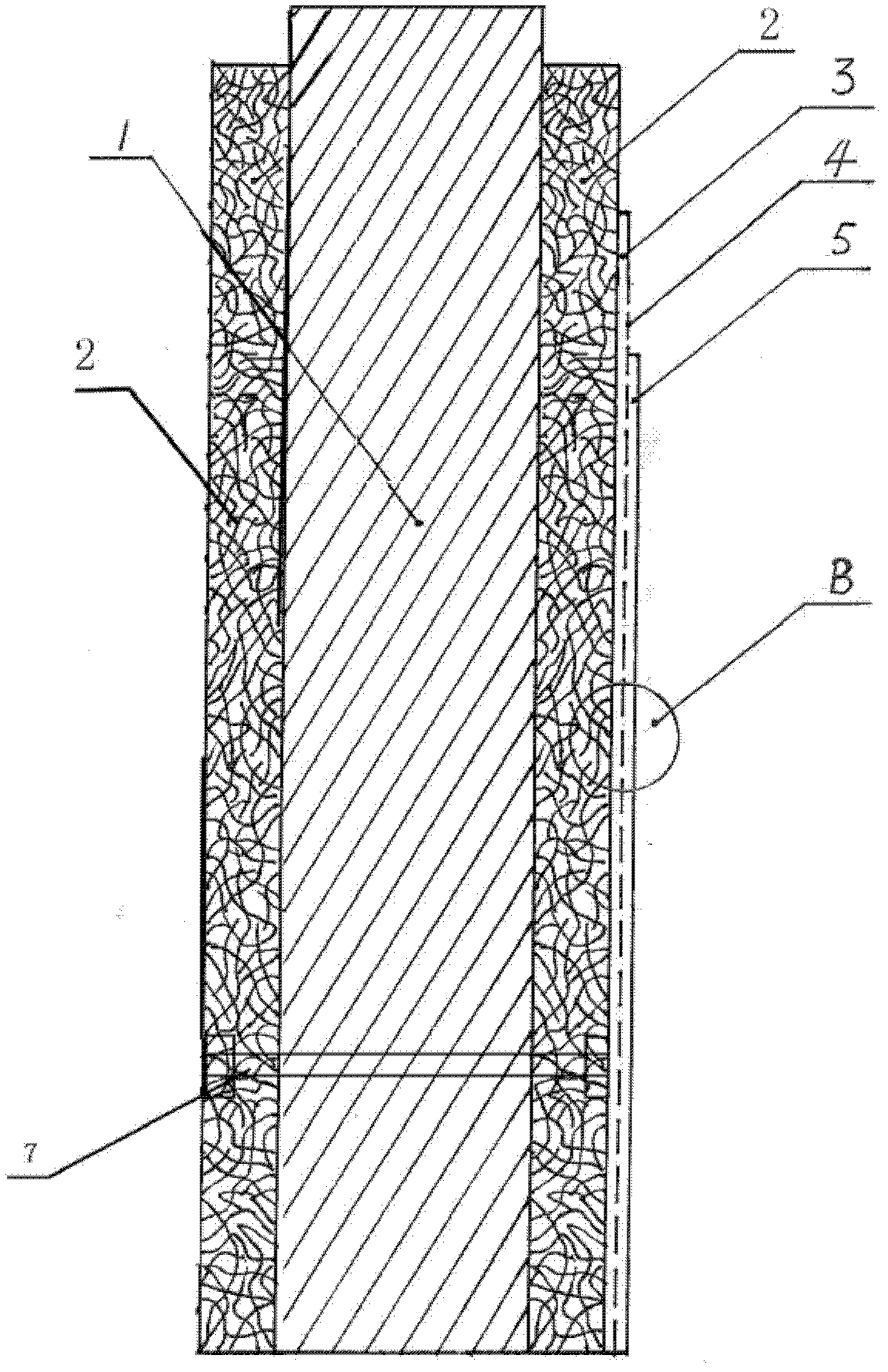

Self-heat preservation system of wood-wool cement board (WWCB) demoulding-free template

A technology of self-insulation and formwork, applied in the direction of insulation, formwork/formwork components, building components, etc., can solve the problems of complex process, affecting the moisture balance of buildings, high cost, etc., and achieve convenient construction, good architectural artistic effect, heat conduction The effect of a small coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

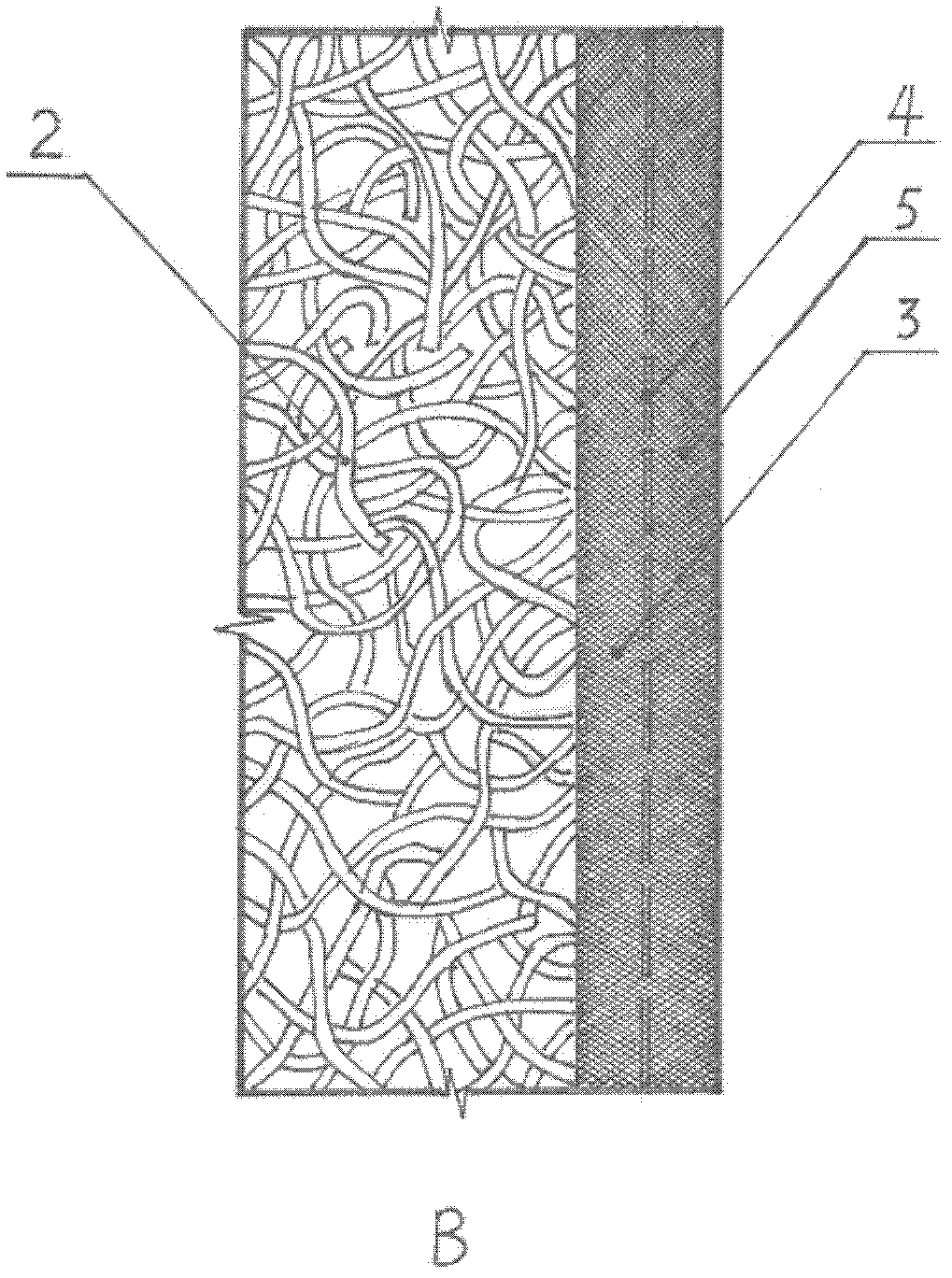

[0027] Finishing primer 3: 30 parts by weight of high-strength cement, 60 parts by weight of composite lightweight aggregate, 2 parts by weight of dispersible latex powder, 0.4 part by weight of short glass fiber, and 6 parts by weight of ultrafine sub-nano powder;

[0028] Finishing surface coating 5: 30 parts by weight of high-strength cement, 60 parts by weight of composite lightweight aggregate, 3 parts by weight of acrylic acid, 0.5 parts by weight of short glass fiber, 5 parts by weight of ultrafine sub-nanometer powder, and 1 part by weight of silicone water repellent .

Embodiment 2

[0030] Finishing primer 3: 20 parts by weight of high-strength cement, 50 parts by weight of composite lightweight aggregate, 1 part by weight of dispersible latex powder, 0.3 parts by weight of short glass fiber, and 3 parts by weight of ultrafine sub-nano powder;

[0031] Finishing surface coating 5: 30 parts by weight of high-strength cement, 70 parts by weight of composite lightweight aggregate, 4 parts by weight of dispersible latex powder, 0.6 part by weight of short glass fiber, 8 parts by weight of ultrafine sub-nanometer powder, silicone hydrophobic 0.8 parts by weight of agent.

Embodiment 3

[0033] Finishing primer 3: 25 parts by weight of high-strength cement, 70 parts by weight of composite lightweight aggregate, 3 parts by weight of dispersible latex powder, 0.6 part by weight of short glass fiber, and 7 parts by weight of ultrafine sub-nano powder;

[0034] Finishing surface coating 5: 30 parts by weight of high-strength cement, 80 parts by weight of composite lightweight aggregate, 4 parts by weight of dispersible latex powder, 0.8 parts by weight of short PP fiber, 8 parts by weight of ultrafine sub-nano powder, organic silicon hydrophobic agent 1.5 parts by weight, iron oxide red 0.5 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com