Back plate for metal wrap through (MWT) solar battery

A solar cell and backplane technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inconvenient output of electric energy and no electrical connection, so as to improve the efficiency of components, increase the partial discharge power, and reduce the shading rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

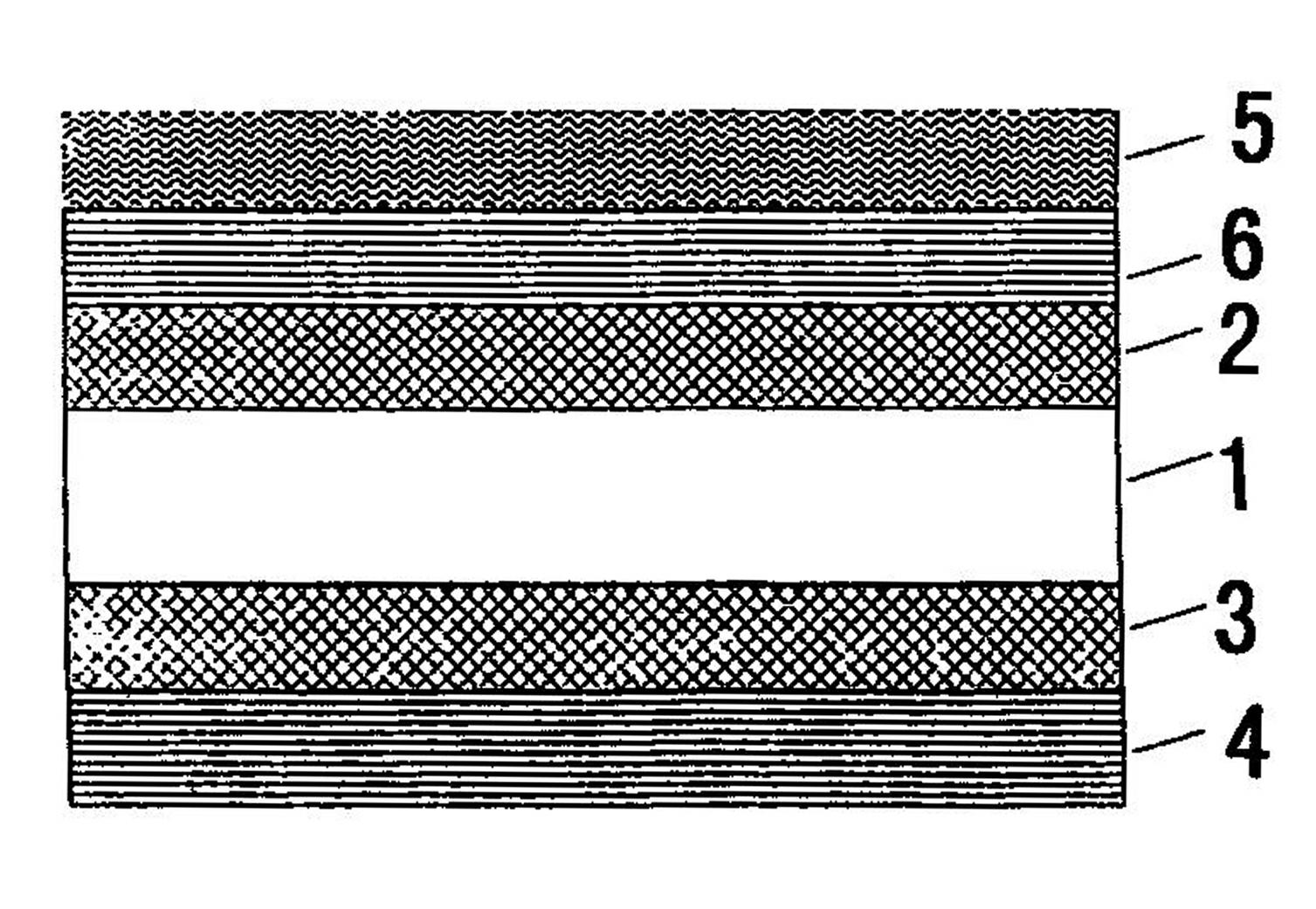

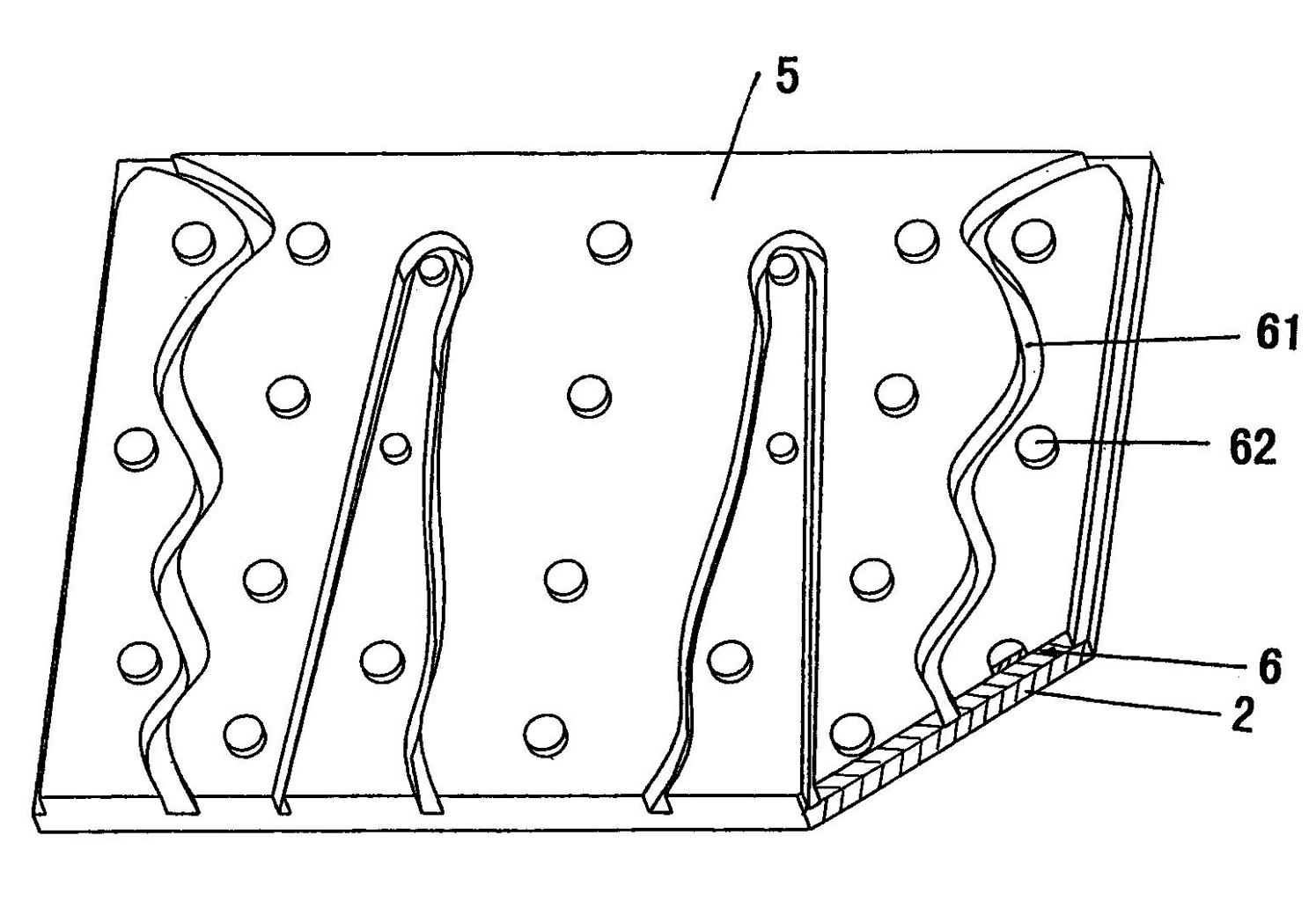

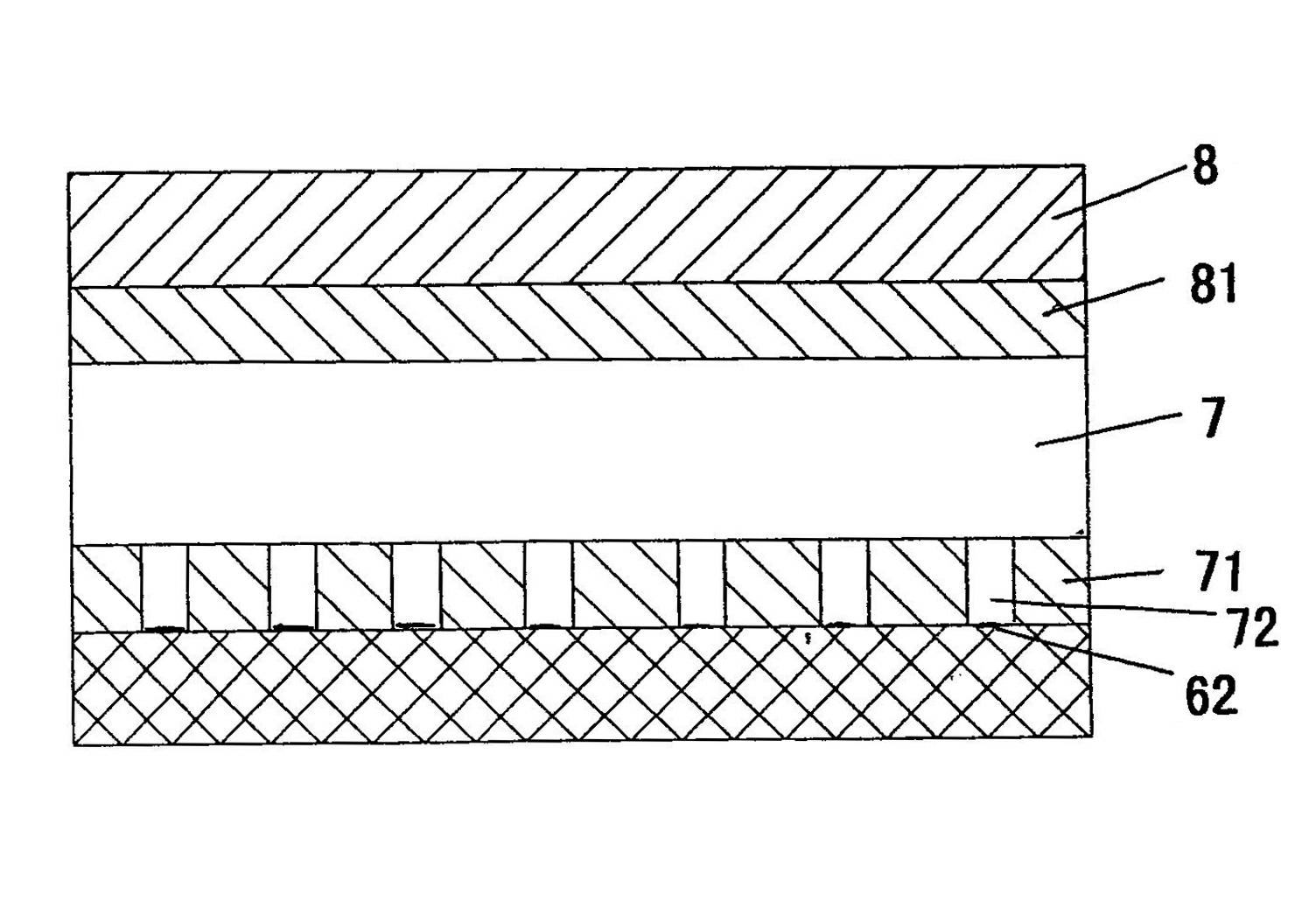

[0024] See figure 1 , shows the cross-section of the MWT solar cell back sheet of the present invention, including the base material layer 1, the first and second adhesive layers 2, 3, the corona-treated weather-resistant layer 4, the insulating layer 5 and the added metal The foil layer 6, the first and second adhesive layers 2 and 3 are all polyurethane adhesives, that is, polyurethane adhesive layers, wherein the first adhesive layer 2 is located on the polyethylene terephthalate, that is, the material is Between the substrate layer 1 and the metal foil layer 6 of polyethylene terephthalate, the side surface of the metal foil layer 6 facing the substrate layer 1 is combined with the substrate layer 1 as a whole. In an example, the metal foil layer 6 is electrolytic copper foil. The second adhesive layer 3 is located between the base layer 1 and the weather-resistant layer 4, and the second adhesive layer 3 combines the surface of the weather-resistant layer 4 facing the...

Embodiment 2

[0028] Only the weather-resistant layer 4 is changed to polyvinyl fluoride (PVF), and the rest are the same as the description of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com