Composite air electrode of lithium air cell and preparation method thereof

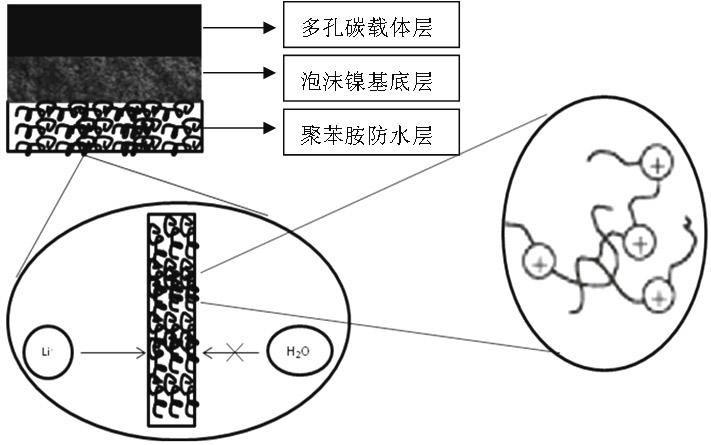

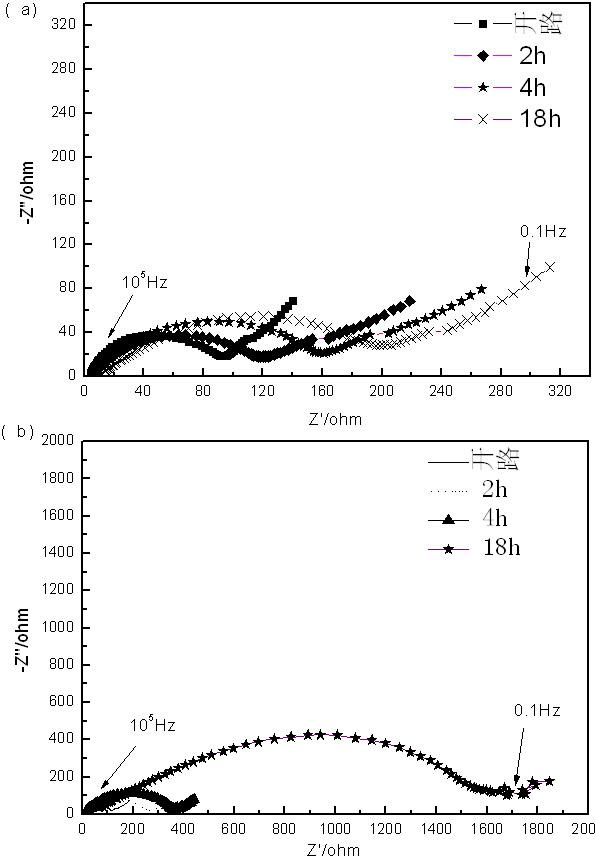

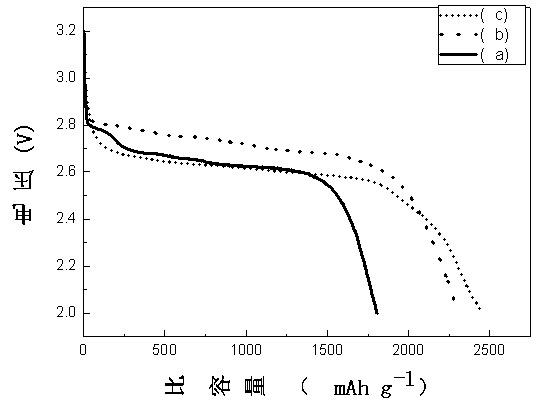

A lithium-air battery, air electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems affecting the battery's high rate performance, reducing oxygen permeability, increasing electrode polarization, etc., to achieve good air permeability , Good water blocking effect, reducing the effect of battery polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. The air-diffused carbon carrier layer is coated on the nickel foam current collector through mesoporous carbon slurry. First, the foam

[0022] Nickel was washed with acetone and deionized water in turn, and then dried in the air, and carbon paper was vacuum-dried at 80°C for 12h. Mesoporous carbon KB (Kenjet Balck) was mixed with PVDF, and N-methylpyrrolidone was used as a solvent, mixed evenly, evenly coated on nickel foam or carbon paper, the solvent was evaporated to dryness, and placed in vacuum at 80°C for 12h.

[0023] 2. Preparation of proton-doped polyaniline with high conductivity. Slowly add aniline to 2 mol / L HCl solution, ultrasonically disperse for 12 h, (NH 4 ) 2 S 2 o 8 Dissolve in 20 mL of deionized water, add it dropwise to the solution while stirring, react at 25°C for 4-6 h, filter the precipitate by centrifugation, wash with 2M HCl solution first, then wash with deionized water, and dry at 60°C for 24h.

[0024] 3. The proton-doped polyani...

Embodiment 2

[0031] 1. The air-diffused carbon carrier layer is coated on the foamed nickel current collector through mesoporous carbon slurry. First, the nickel foam was washed with acetone and deionized water in sequence, then dried in air, and vacuum-dried with carbon paper at 80 °C for 12 h. Mesoporous carbon KB (Kenjet Balck) was mixed with PVDF, and N-methylpyrrolidone was used as a solvent, mixed evenly, and evenly coated on carbon paper, the solvent was evaporated to dryness, and placed in vacuum at 80°C for 12h.

[0032] 2. Then prepare proton-doped polyaniline with high conductivity, aniline is slowly added to 2 mol / L HCl solution, ultrasonically dispersed for 12 h, (NH 4 ) 2 S 2 o 8 Dissolve in 20 mL of deionized water, add it dropwise to the solution while stirring, react at 25°C for 4-6 h, filter the precipitate by centrifugation, wash with 2M HCl solution first, then wash with deionized water, and dry at 60°C for 24h.

[0033] 3. The proton-doped polyaniline powder mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com