Method of preparing 1550nm laser utilizing silicon-based InGaAsP as active area

A technology of lasers and active regions, applied in lasers, laser components, semiconductor lasers, etc., can solve the problem that the silicon-based light emission problem has not been solved well, affect the quality of the epitaxial layer, etc., to reduce defects, improve quality, The effect of improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] see Figure 1 to Figure 10 , the invention provides a method for preparing a silicon-based InGaAsP 1550nm laser with an active region, comprising the following steps:

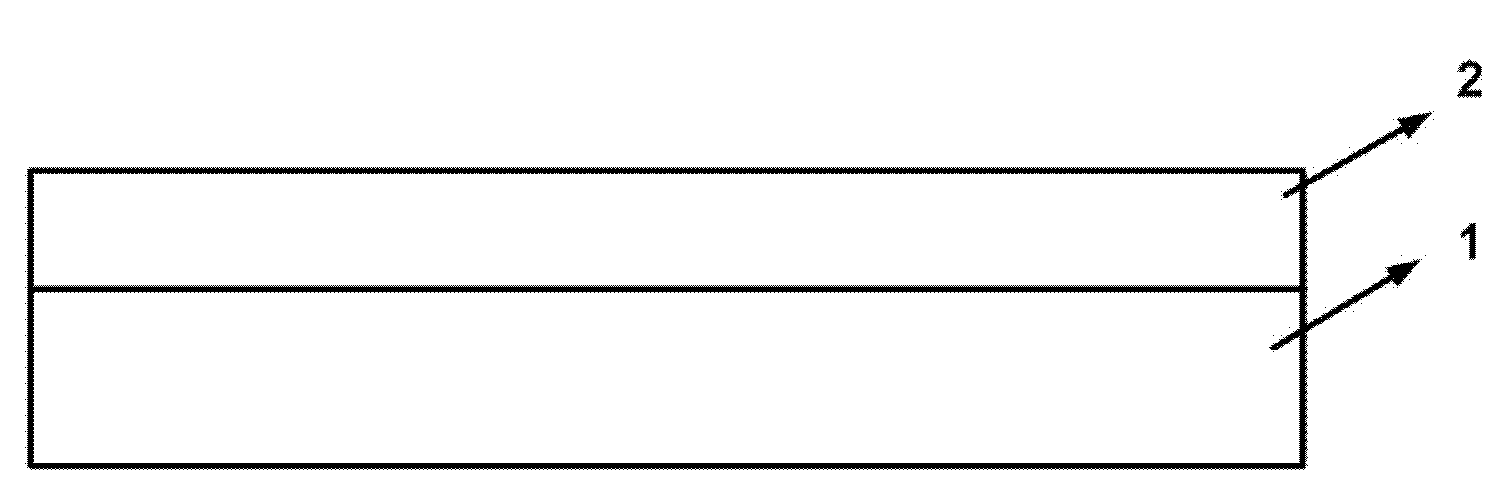

[0026] Step 1: growing a silicon dioxide layer 2 on a silicon substrate 1, wherein the silicon substrate 1 is n-type high-resistance (001) silicon, the resistivity is greater than 2000 ohm cm, and the thickness of the silicon dioxide layer 2 is 500nm- 600nm.

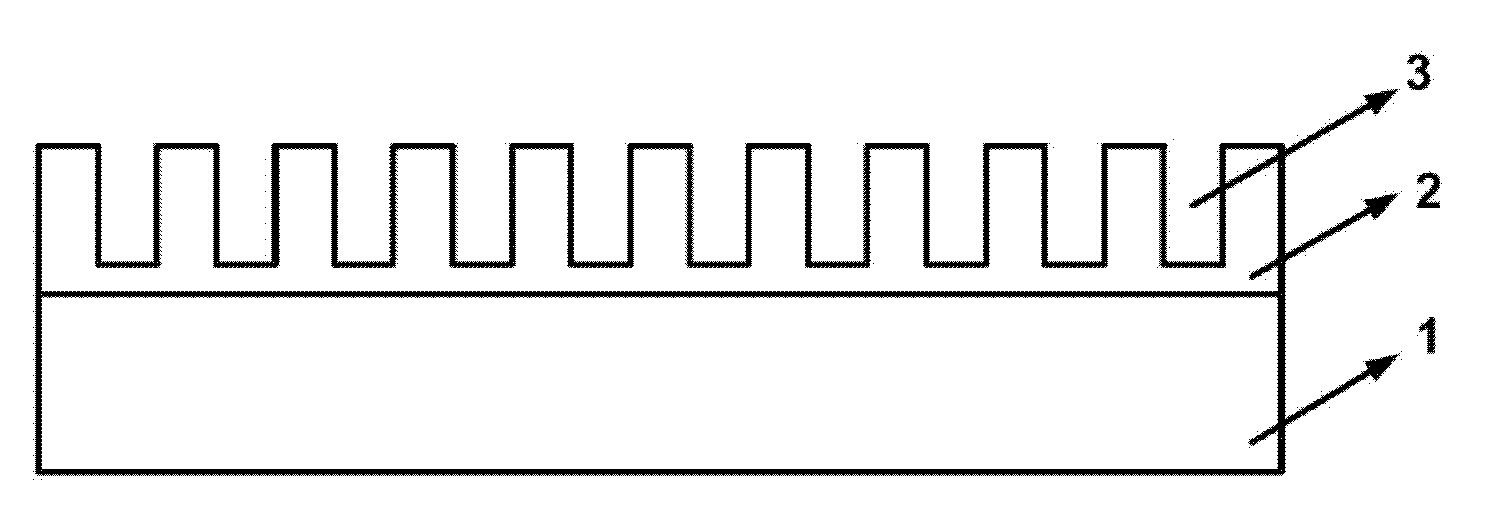

[0027] Step 2: using holographic exposure and ICP methods to etch a groove 3 on the silicon dioxide layer 2 along the direction of the silicon substrate 1, the width of which is 200-300 nm, and the depth is the same as the thickness of the silicon dioxide layer 2 same, and more than ten nanometers of silicon dioxide is left at the bottom of the trench 3 to protect the silicon substrate 1 .

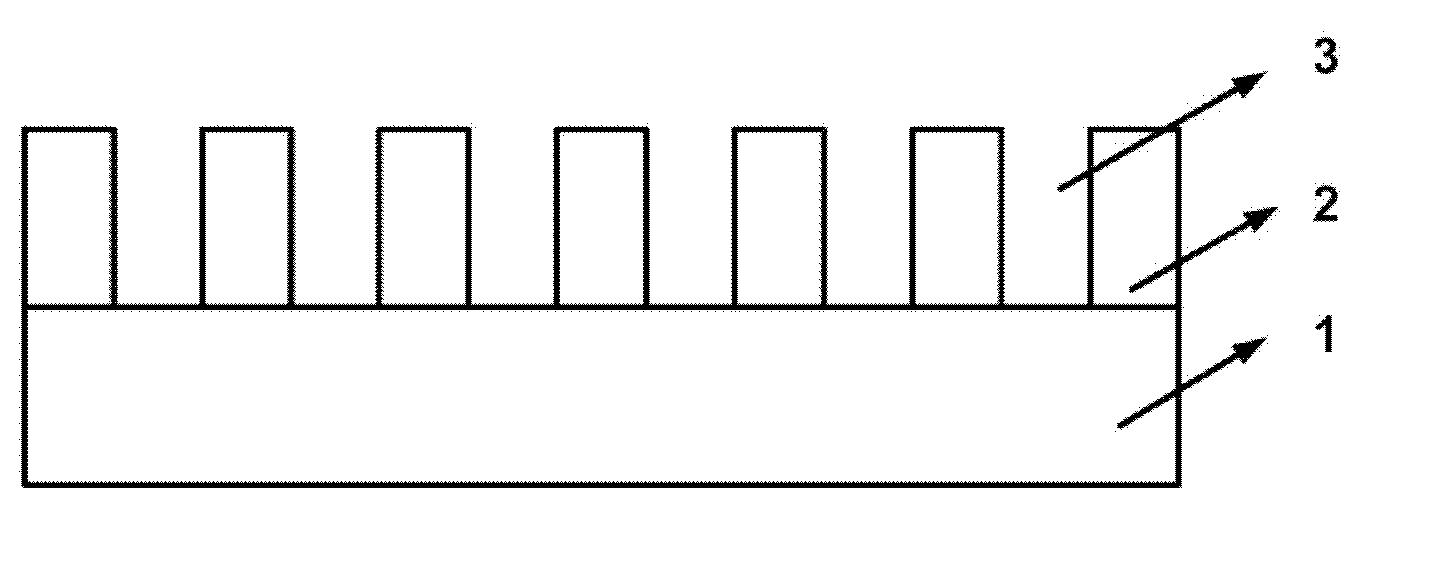

[0028] Step 3: Use piranha and SC respectively 2 , HF and deionized water cleaning, remove the remaining silicon dioxide layer 2 at the bottom of the trenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com