Sectional type lightning guide strip and manufacturing method thereof

A flow-guiding strip and segmented technology is applied in the field of segmented lightning guide strips and their production, which can solve the problems of difficult processing and high cost, and achieve the effects of low cost, convenient processing and use, and reduced breakdown voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

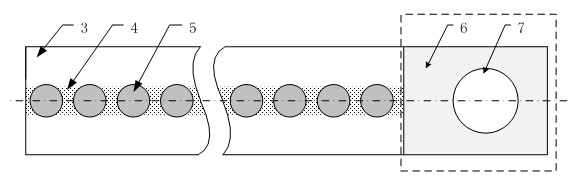

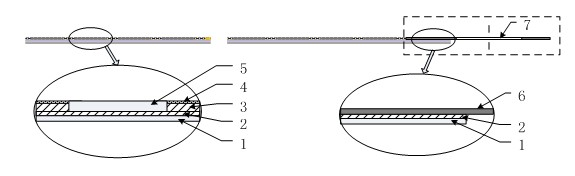

[0052] figure 1 with figure 2 Among them, the insulating base tape 1 is made of polyester film (PET), and its thickness is generally 0.1mm. The width is from 0.5mm to 2mm, cut from the whole polyester film, and the length is determined according to actual needs.

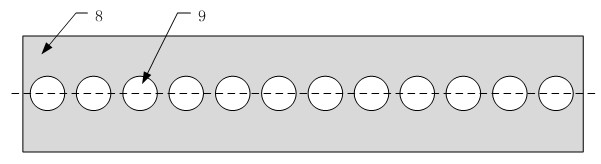

[0053] The first adhesive layer 2 and the other adhesive layer 3 are both flexible epoxy adhesives, which are flexible after curing, so that the entire flow guiding strip can be bent so as to be pasted on curved equipment surfaces. An adhesive layer 2 is relatively thin, generally 0.1 mm to 0.2 mm, and is applied along the center of the insulating base tape 1 , and is mainly used for preliminary positioning of the metal sheet 5 . The location of the metal sheet 5 on the insulating base tape 1 can be by means of such as image 3 The template 8 shown realizes that the hole 9 on the template 8 is consistent with the size of the metal sheet, so that the metal sheet just fits into the hole. In order to reduce the br...

Embodiment 2

[0057] figure 1 with figure 2 The dotted line box is the ground terminal 6, and the dotted line box indicates that this part can be omitted, because some applications do not need the ground terminal. The ground terminal 6 is cut from a thin copper sheet with a thickness of 0.1-0.5mm. The mounting hole 7 is processed by stamping, and the diameter of the hole is determined according to the size of the screw hole at the actual mounting position. The shape of the mounting hole 7 includes but is not limited to a circle or a rounded rectangle, Figure 5 In the example, the mounting hole 7 is a rounded rectangle.

specific Embodiment approach

[0060] 1) Cut the polyester film into long strips with a width of 0.5mm to 5mm. The length is determined according to the needs. Generally, a single piece does not exceed 1m. figure 2 in 1);

[0061] 2) On the thin metal plate (thickness 0.1mm ~ 0.5mm), the metal sheet is cut out by laser cutting, and the shape of the metal sheet is circular or rhombus (such as figure 1 , Figure 4 5 in), the size is 1mm ~ 5mm, it should be ensured that the cut metal sheet is free of burrs and metal residues;

[0062] 3) Cut out the shape of the grounding terminal with a thin copper sheet (such as figure 1 , Figure 5 shown in 6), punch out the mounting holes by punching (such as figure 1 , Figure 5 shown in 7);

[0063] 4) Apply a thin layer of adhesive to the center of the insulating base tape (such as figure 2 2 in), the adhesive thickness is 0.1mm~0.2mm;

[0064] 4), using templates (such as image 3 As shown), the metal sheet is positioned on the insulating base tape, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com