Method for preparing instant dried corn steep liquor powder by using corn steep liquor

A technology of corn steep liquor dry powder and corn soaking liquid, which is applied in the direction of biochemical equipment and methods, food preparation, application, etc., can solve the problems of increasing the labor intensity of operation, easy to produce precipitation, and occupying a large space, so as to facilitate freezing or Drying and drying, easy storage and transportation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

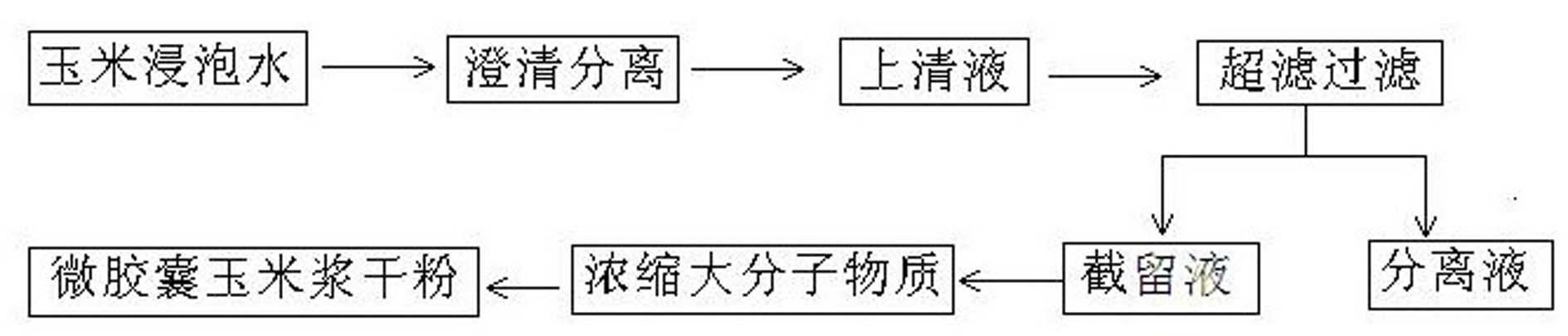

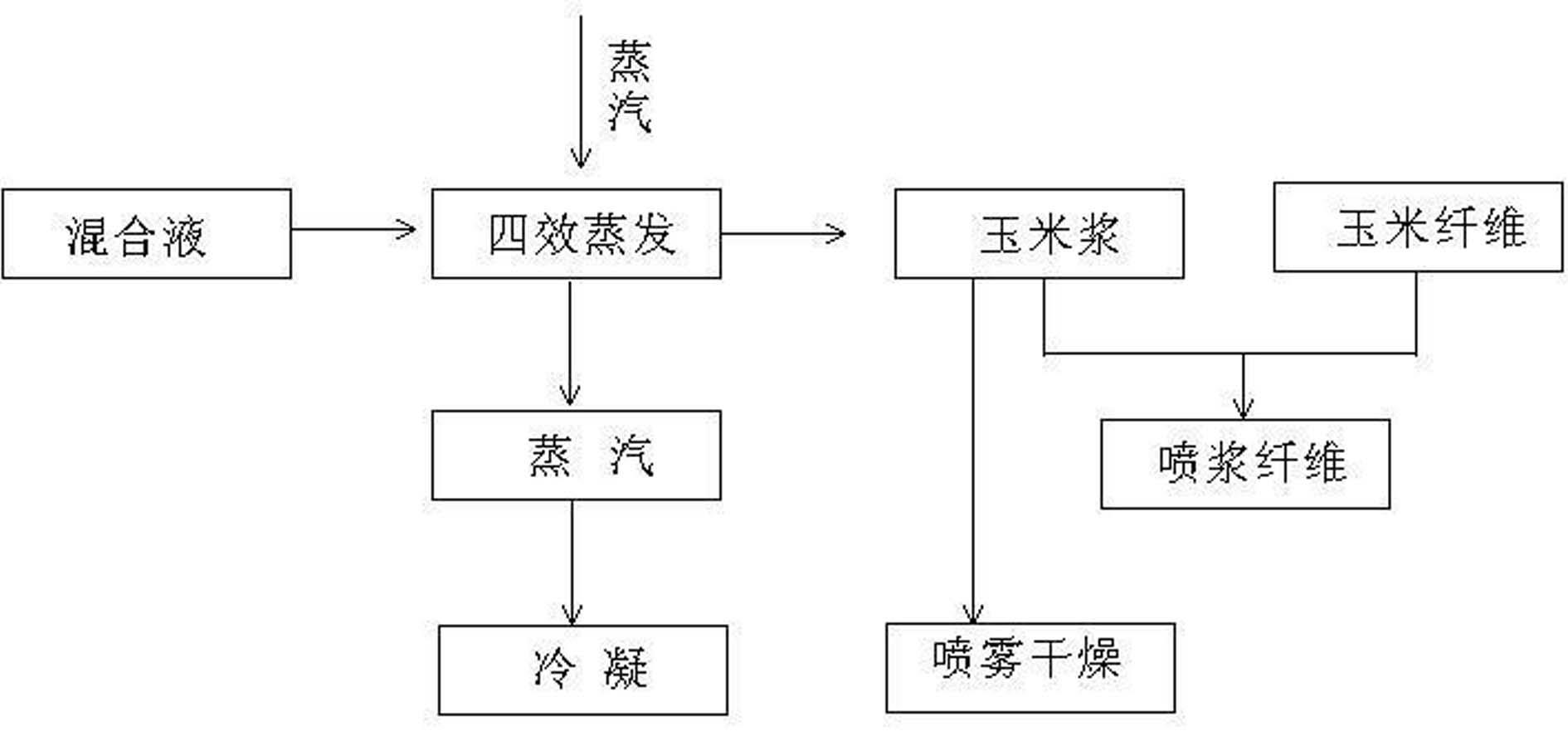

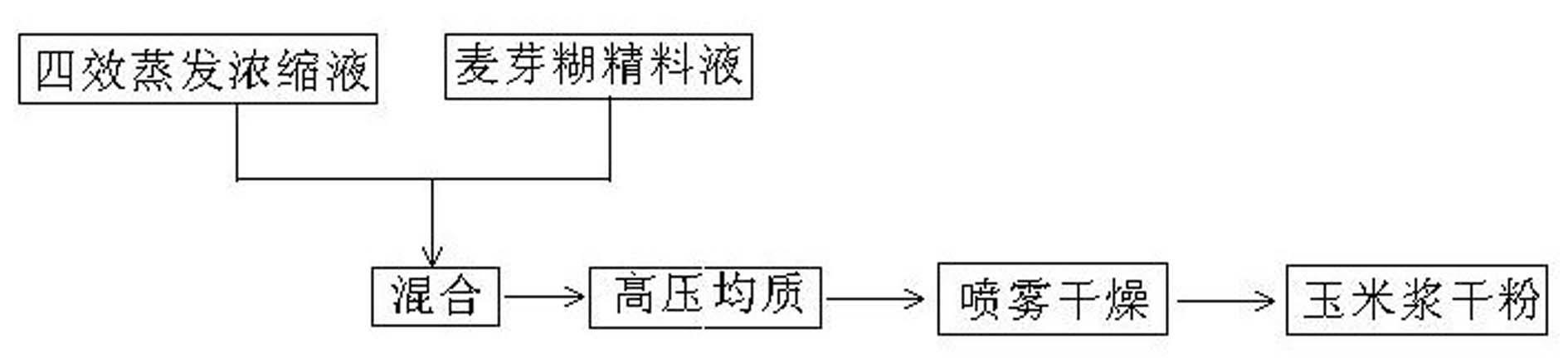

[0019] Such as figure 1 As shown, the method of the present invention for preparing instant corn steep liquor dry powder by using corn soaking liquid comprises the following steps: comprising clarification and separation, ultrafiltration filtration, four-effect evaporation, and spray drying.

[0020] Firstly, the corn soaking liquid is pretreated by clarification and separation method, and then the pretreated liquid is filtered by ultrafiltration membrane using flat ultrafiltration membrane equipment. The selected ultrafiltration membrane has a membrane area of 1 m 2 , the membrane material is PE, the relative cut-off molecular weight of the ultrafiltration membrane is 20KD, the pore size is 5000 Daltons, the operating temperature of the system is 25°C, the working pressure is 0.2MPa, and the inlet flow rate is 160L / min, thus the permeate and The retentate, wherein the molecular weight of the permeate is less than 5000 Daltons, and the molecular weight of the retentate is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com