Method for preparing supported corrosion inhibitor

A corrosion inhibitor and supported technology, applied in the field of preparation of supported corrosion inhibitors, can solve the problems of carrying away or extracted substances, waste, limiting the universality of corrosion inhibitors, etc. Effects of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

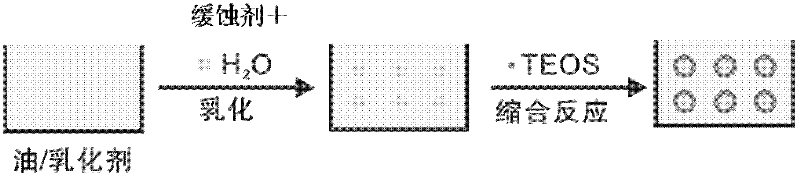

Method used

Image

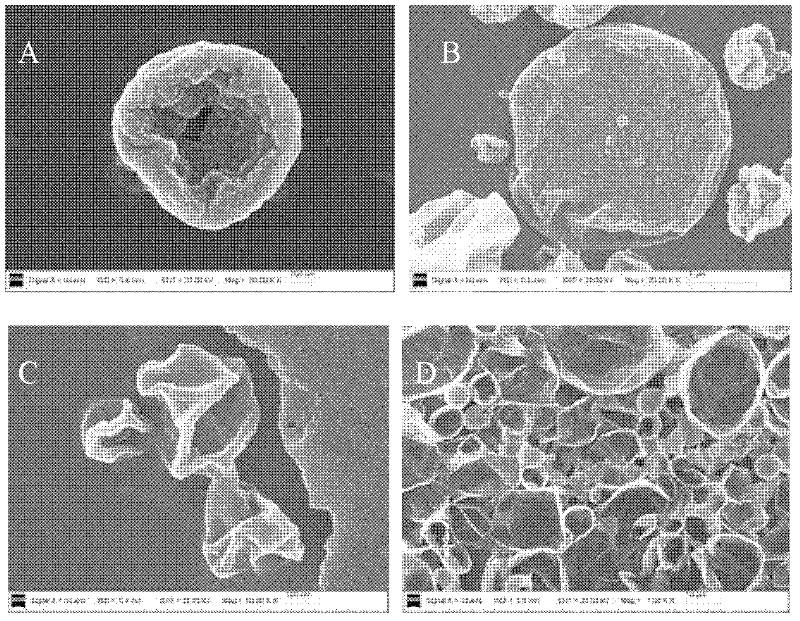

Examples

Embodiment 1

[0031] 1) Experimental part

[0032] 1.1) Raw materials

[0033] Cyclohexane, analytically pure, Beijing Huateng Chemical Co., Ltd.; sodium tungstate, analytically pure, Shantou Xilong Chemical Co., Ltd.; sorbitan monooleate (Span80), chemically pure, Tianjin Guangfu Fine Chemical Research Institute; Octylphenol polyoxyethylene ether-10 (OP-10), chemically pure, Tianjin Guangfu Fine Chemical Research Institute; tetraethyl orthosilicate (TEOS), analytically pure, Beijing Yili Fine Chemicals Co., Ltd.; ammonia water ( The mass fraction is 25%), analytically pure, Beijing Chemical Plant.

[0034] 1.2) Operation method

[0035] Dissolve Span80 and OP-10 emulsifiers in cyclohexane, stir with a magnetic rotor, fully dissolve, transfer to a four-necked reaction flask with a condenser, stirring, and constant pressure dropping funnel, and stir (about 200r / min) for 1h And heated to 35°C, dissolved ammonia and sodium tungstate in water and slowly added dropwise to the reaction bottle ...

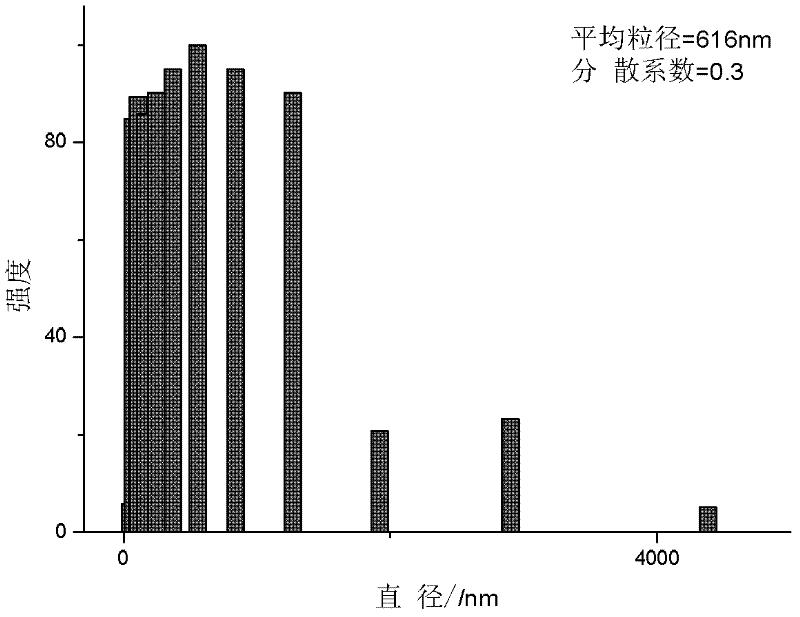

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com