Manufacturing method of convective acceleration sensor chip based on temperature sensitive resistor

A technology of acceleration sensor and sensitive resistor, which is applied in the direction of acceleration measurement using inertial force, the process for producing decorative surface effects, and the manufacture of microstructure devices, etc. It can solve problems such as complex connections, achieve good reliability, and meet marketization demand, to achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

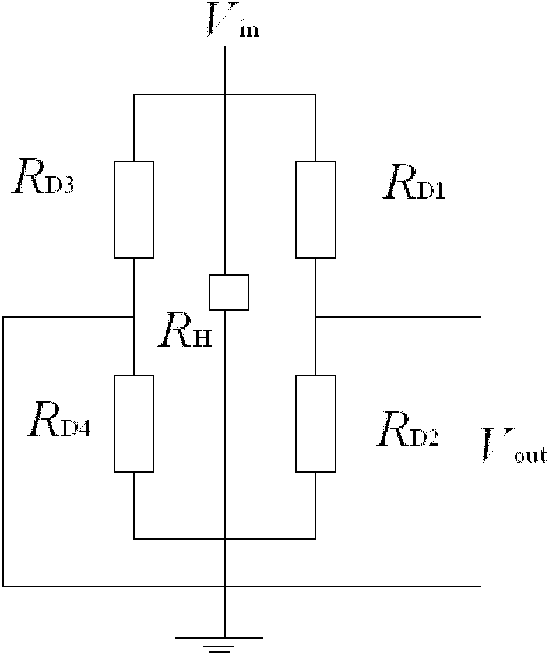

[0044] The thermal convection acceleration sensor made in this embodiment is based on temperature-sensitive resistors and adopts four polysilicon temperature-sensitive resistors. The heat source (heater) is composed of polysilicon heating resistors, and the heating resistors are suspended in the middle of the sealed cavity. At zero time, an isothermal convection field is formed in the cavity; when there is acceleration, a small air mass is caused to convect freely, forming a temperature gradient field in the cavity. Two pairs of polysilicon temperature-sensitive resistors are placed on both sides of the heater equidistantly and symmetrically (coaxially), and are connected to form a Wheatstone detection bridge. Since the temperature sensitive resistors on both sides are subjected to different temperatures, the temperature sensitive resistors undergo different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com