Method for preparing nanometer cerium oxide (CeO2) particles through microemulsion

A microemulsion and nanotechnology, applied in nanotechnology, chemical instruments and methods, rare earth metal compounds, etc., can solve the problems of limited particle application and development, uneven dispersion, product agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

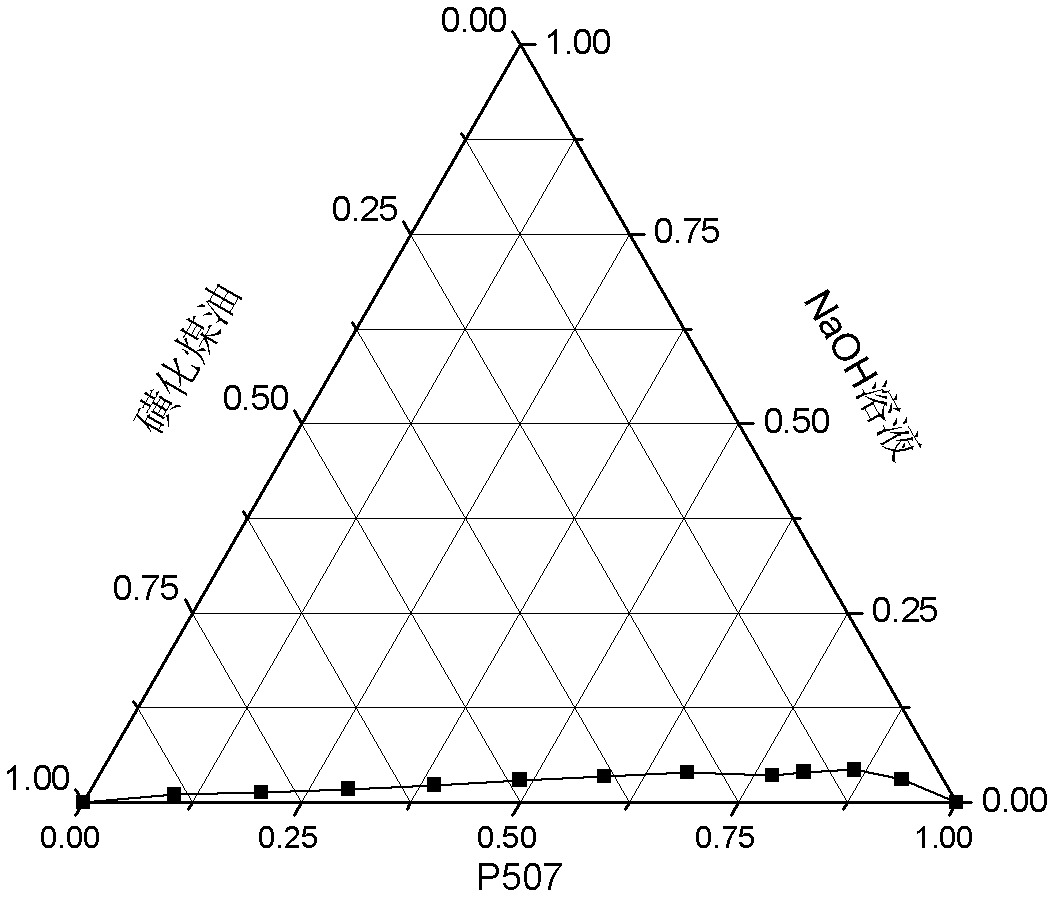

[0035] 1. Mix surfactant P507 and oil phase sulfonated kerosene evenly, wherein the mass ratios of P507 and sulfonated kerosene are 9:1, 8:2, 7:3, 6:4, 5:5, 4:6 respectively , 3:7, 2:8, 1:9.

[0036] 2. Use 2-10mol / L strong alkali solution NaOH to titrate the above-mentioned mixed solutions with different mass ratios to saponify them until a clear and uniform solution is obtained by visual observation. Determine the water / oil (W / O) according to the turbidity of the system ) of the microemulsion region. At this time, the system contains three substances, surfactant P507, sulfonated kerosene in the oil phase and strong alkali solution in the water phase. The ternary phase diagram is drawn according to the experimental data of the three components.

[0037]3. According to the specific embodiment, the mass ratio range of P507: sulfonated kerosene: NaOH (in terms of solid content) is 9.9~92.21: 4.72~89.11: 0.99~4.31, wherein the optimal range is 77.15~92.21: 4.72~19.29: From 3.07...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com