Monodisperse cerium oxide nanoparticle and preparation method thereof

A nanoparticle and cerium oxide technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of wide product particle size distribution, complex preparation process, powder shape and particle size distribution, etc. problems, to achieve the effect of narrow size distribution, good product dispersion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

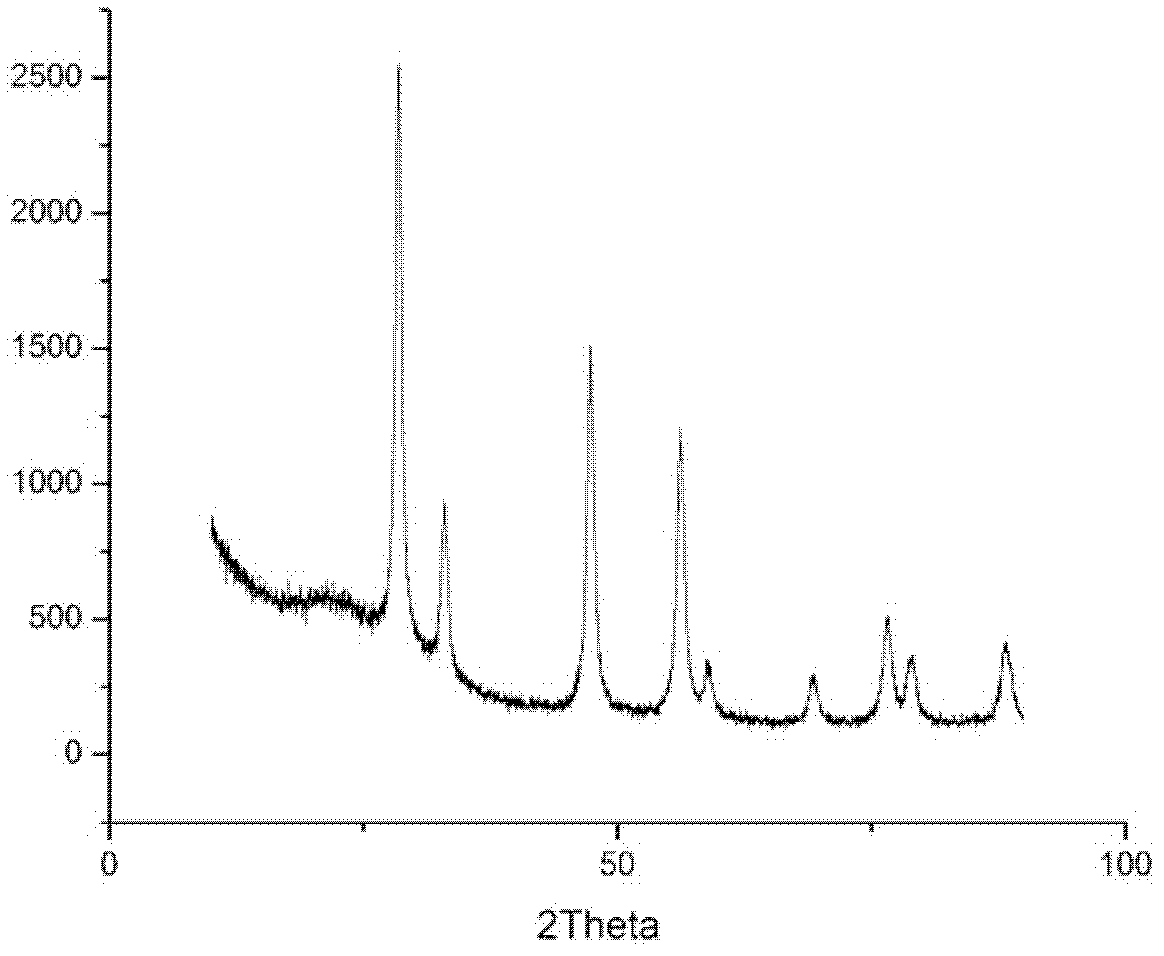

Image

Examples

Embodiment 1

[0019] Weigh 2.74g of ceric ammonium nitrate, 1.0g of sodium nitrate and 0.1g of PEG 2000, dissolve in 15ml of water, and mix thoroughly by magnetic stirring to obtain a clear solution. Transfer the solution to a reaction kettle, put it in an oven, and conduct a hydrothermal reaction at 200°C for 10 hours. After washing with water, ethanol and centrifugation, the precipitate is dried in an oven at 80°C to obtain monodisperse cerium oxide with a particle size of 240±2nm.

Embodiment 2

[0021] Weigh 4.11g of ceric ammonium nitrate, 1.5g of sodium nitrate and 0.01g of PEO, dissolve in 15ml of water, and mix thoroughly by magnetic stirring to obtain a clear and transparent solution. Transfer the solution to a reaction kettle, put it in an oven, and conduct a hydrothermal reaction at 220° C. for 1 hour. After washing with water, ethanol and centrifugation, the precipitate is dried in an oven at 80°C to obtain monodisperse cerium oxide with a particle size of 270±3nm.

Embodiment 3

[0023] Weigh 2.74g of ceric ammonium nitrate, 2.0g of lithium nitrate and 0.1g of PVP, dissolve in 15ml of water, and mix thoroughly by magnetic stirring to obtain a clear solution. The solution was transferred to a reaction kettle, put into an oven, and reacted hydrothermally at 120° C. for 100 hours. After washing with water, ethanol and centrifugation, the precipitate is dried in an oven at 80°C to obtain monodisperse cerium oxide with a particle size of 180±3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com