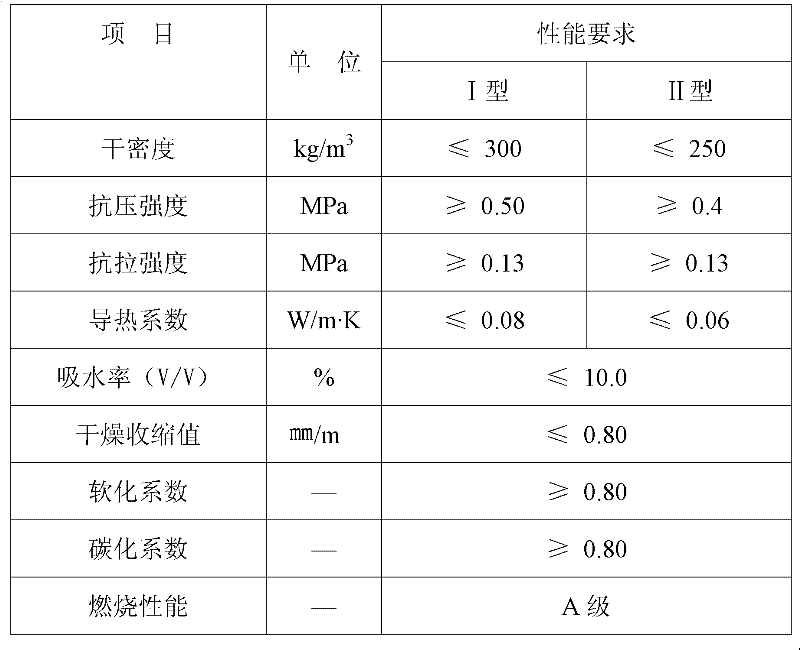

Inorganic fiber reinforced cement heat preservation product

A thermal insulation product and inorganic fiber technology, which is applied in the field of inorganic fiber reinforced cement thermal insulation products, can solve problems affecting the promotion and use of materials, unqualified actual testing, unsatisfactory application effects, etc., to achieve stable physical and chemical properties, simple construction, The effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Powder preparation: Take 480kg of sulfoaluminate cement, 250kg of fly ash, 250kg of expanded perlite, and 20kg of sulfate according to the mass ratio, and mix them to obtain 1000kg of powder.

[0029] 2) Preparation of liquid material: Take 15kg of commercially available nonionic surfactant as foaming agent according to mass ratio, 10kg of hydroxypropyl methylcellulose, 10kg of basalt fiber as toughening agent, 20kg of methyl silicone oil, mix, Make up 1000kg with water, and pack it to get the liquid material.

[0030] When in use, the prepared liquid material and powder material are pre-foamed and stirred according to the mass ratio of liquid material: powder material = 1: 1, and then transported to the mold, then dried at a high temperature of 85°C for 2 hours, then demoulded, and transferred to the mold. Put it in the warehouse for natural conservation for 3 days.

Embodiment 2

[0032] 1) Powder preparation: Take 680kg of aluminate cement, 50kg of heavy calcium carbonate, 100kg of light calcium carbonate, 150kg of closed-cell vermiculite, and 20kg of sulfate according to the mass ratio, and mix to obtain 1000kg of powder.

[0033] 2) Preparation of liquid material: Take 10 kg of rosin soap as foaming agent, 10 kg of hydroxyethyl cellulose, 10 kg of diabase fiber as toughening agent, and 20 kg of organic silicon according to the mass ratio, mix and make up 1000 kg with water to obtain liquid material.

[0034] When in use, the prepared liquid material and powder material are pre-foamed and stirred according to the mass ratio of liquid material: powder material = 1: 1, and then transported to the mold, then dried at a high temperature of 85°C for 2 hours, then demoulded, and transferred to the mold. Put it in the warehouse for natural conservation for 3 days.

[0035] It should be noted that the above cement is selected from one or more combinations of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com