Super-micro powder combined impervious spinel brick for refining furnace lining and preparation method

A spinel brick and ultrafine powder technology, applied in the field of chrome-free refractories, can solve the problems of inability to meet environmental protection requirements, pollute the environment, pollute the air, etc., and achieve the effects of reducing and alleviating the energy crisis, high bulk density, and high product strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

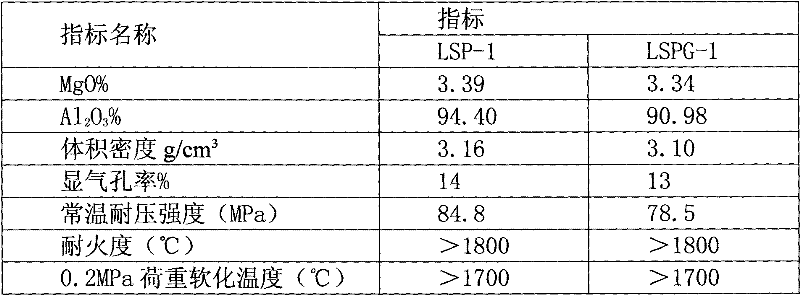

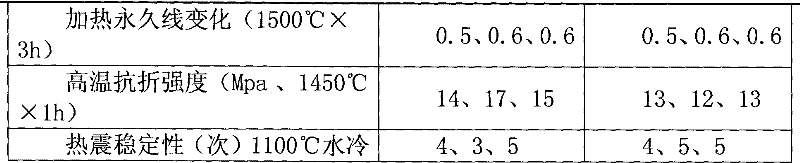

Embodiment 1

[0027] Fused alumina-rich spinel (Al 2 o 3 % content ≥ 90%)) 63 parts, pre-synthesized spinel (single or composite use of fused and sintered spinel) 20 parts, alumina micropowder 17 parts; The ratio of the total weight of the synthesized spinel to the metal is: binder 4%, pre-mixed in a strong mixer for 15 minutes, and the mixed material is used for later use; the mixed material is weighed according to the weight requirement and then poured into the pre-mixed In the assembled mold, carry out high-pressure molding; after forming, measure according to the size requirements of the brick, and test the indicators of the embryo body in time; put the formed brick into the dryer for drying, the drying temperature is -180 °C at room temperature, and the drying time is 31 hours; The dried bricks are fired in a high-temperature kiln. After firing, the temperature is gradually lowered for 19 hours. After the temperature drops below 100°C, it is released from the furnace. After selection...

Embodiment 2

[0029] Fused alumina-rich spinel (Al 2 o 3 % content ≥ 90%)) 64 parts, pre-synthesized spinel (single or composite use of fused and sintered spinel) 20 parts, alumina micropowder 16 parts; The ratio of the total weight of the synthesized spinel to the metal is: 4.5% binder, pre-mixed in a strong mixer for 16 minutes, and the mixed material is ready for use; the mixed material is weighed according to the weight requirement and poured into the pre-mixed In the assembled mold, carry out high-pressure molding; after forming, measure according to the size requirements of the brick, and test the indicators of the embryo body in time; put the formed brick into a dryer for drying, the drying temperature is -180°C at room temperature, and the drying time is 33 hours; The dried bricks are fired in a high-temperature kiln. After firing, the temperature is gradually lowered for 24 hours. After the temperature drops below 60°C, it is released from the furnace. After being selected accord...

Embodiment 3

[0031] Fused alumina-rich spinel (Al 2 o 3% content ≥ 90%)) 65 parts, pre-synthesized spinel (single or composite use of fused and sintered spinel) 20 parts, alumina micropowder 15 parts; The ratio of the total weight of the synthesized spinel to the metal is: 4.5% binder, pre-mixed in a strong mixer for 17 minutes, and the mixed material is set aside; the mixed material is weighed according to the weight requirement and then poured into the pre-mixed In the assembled mold, perform high-pressure molding; after forming, measure according to the size of the adobe, and test the indicators of the embryo body in time; put the formed adobe into a dryer for drying at room temperature -180°C for 35 hours; The dried bricks are fired in a high-temperature kiln. After firing, gradually lower the temperature for 25 hours. After the temperature drops below 50°C, it will be released from the furnace. After selection according to the size requirements, it will be made into superfine powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com