Aryl tertiary aliphatic amine and preparation method thereof

A technology of aliphatic tertiary amines and aryl groups, which is applied in the field of surfactant synthesis, which can solve problems such as high raw material prices, restrictions on the wide application of technologies, and low product yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

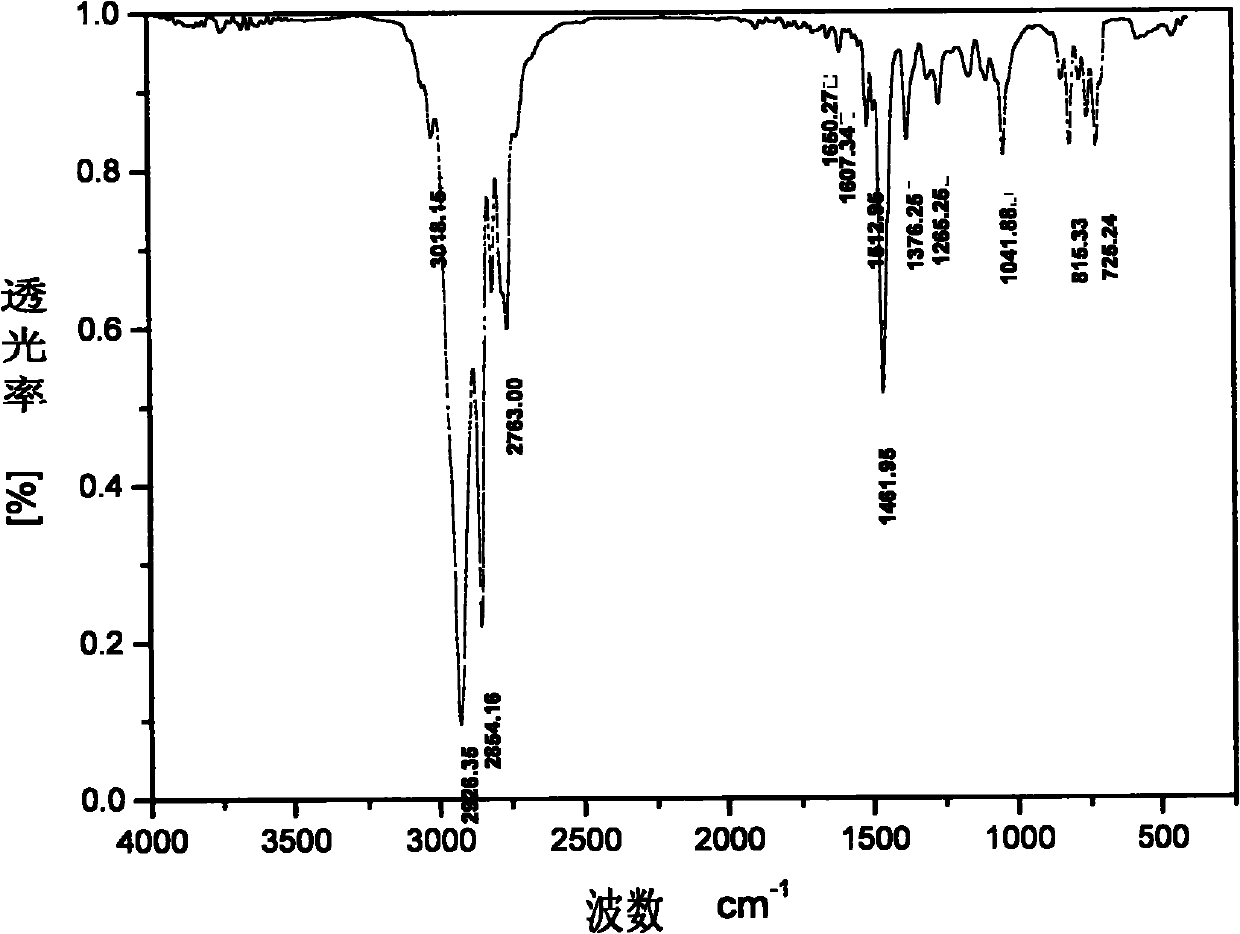

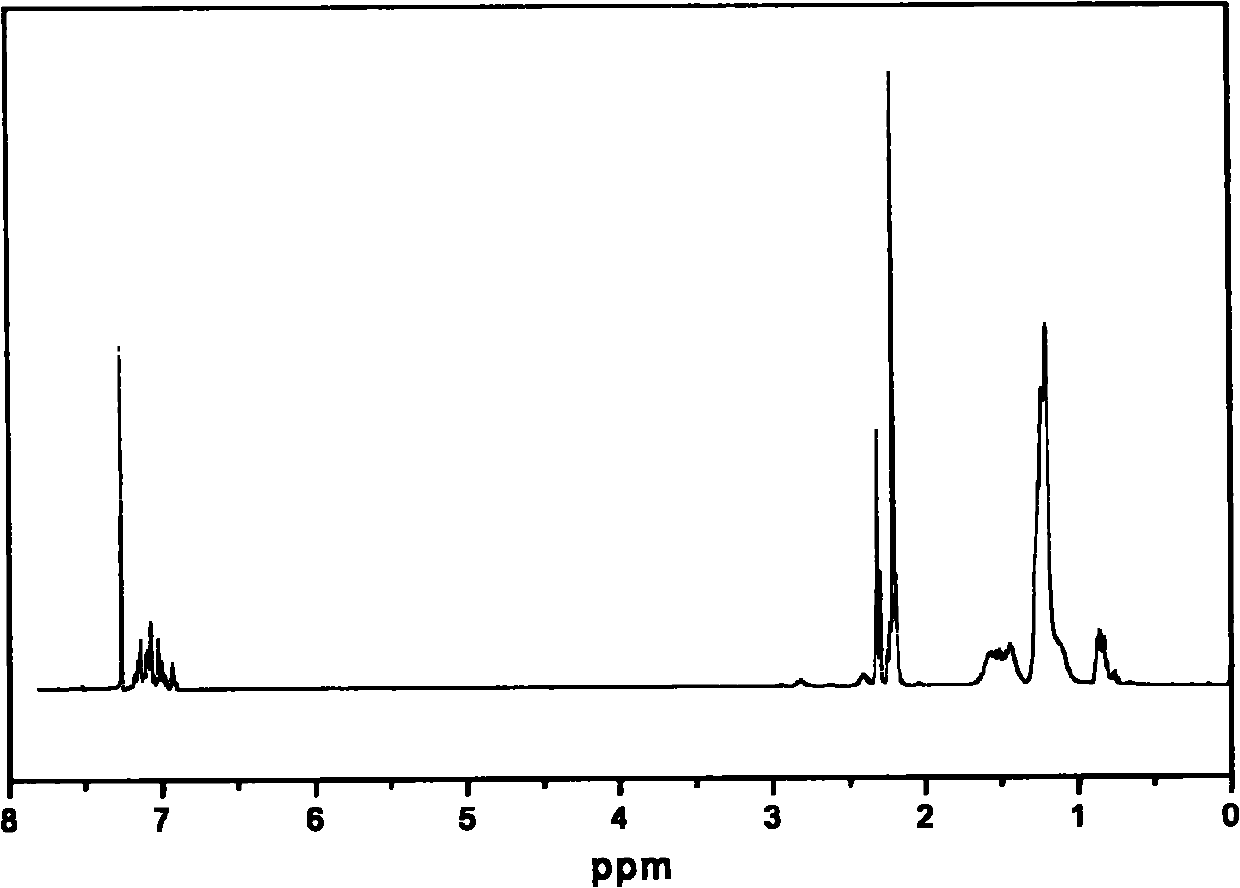

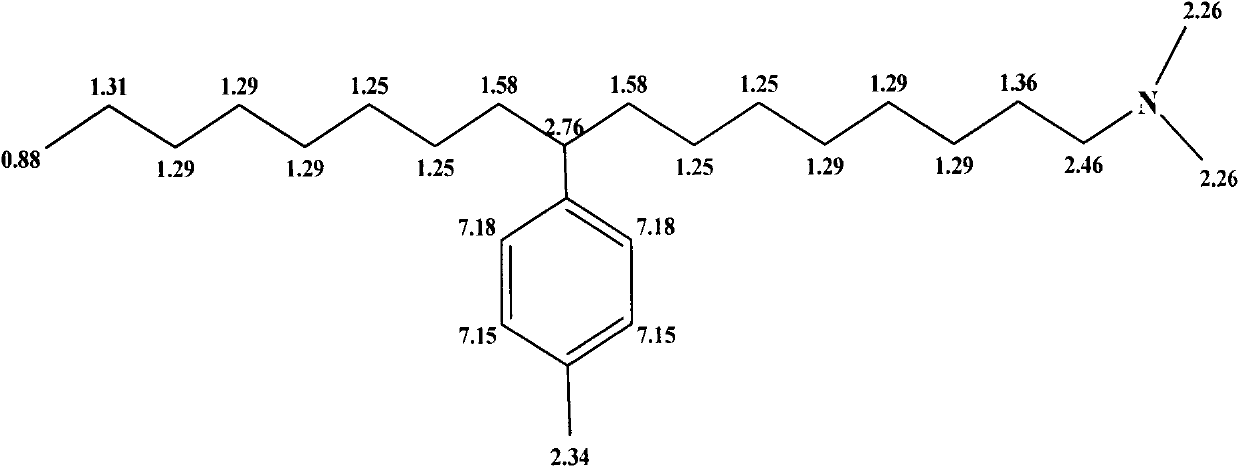

Method used

Image

Examples

Embodiment 1

[0042] (1) Esterification of rectified oleic acid with methanol: Mix oleic acid and methanol (excess methanol), add catalyst concentrated sulfuric acid or p-toluenesulfonic acid, and heat to reflux for 10 hours. Cool, neutralize with sodium methoxide to pH 8-9, wash with water until neutral, dry with anhydrous calcium chloride, and carry out vacuum distillation to obtain methyl oleate;

[0043] (2) Fowler's Alkylation: In a sealed reaction kettle, add (3.5mol) industrial toluene and (0.75mol) methanesulfonic acid, blow with nitrogen for 10min at room temperature, and then raise the temperature to 120- 135°C, then drop (1 mol) methyl alkenyl carboxylate, the reaction product of step (1), for a period of 6 hours. After the dropwise addition, continue the reaction for 3 hours. Cool to room temperature, let stand to separate layers, add slowly dropwise with ice water (equal volume to methanesulfonic acid), wash three times, separate the aqueous solution of methanesulfonic acid in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com