Preparation method of oxidized regenerated cellulose (ORC) absorbable hemostasis material

A technology for regenerated cellulose and hemostatic material, which is applied in the field of preparation of oxidative regenerated cellulose absorbable hemostatic material, can solve the problems of difficult control of the reaction process, pollution of the environment, unsuitable for industrialized production and the like, and achieves low cost, easy reaction process, The effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

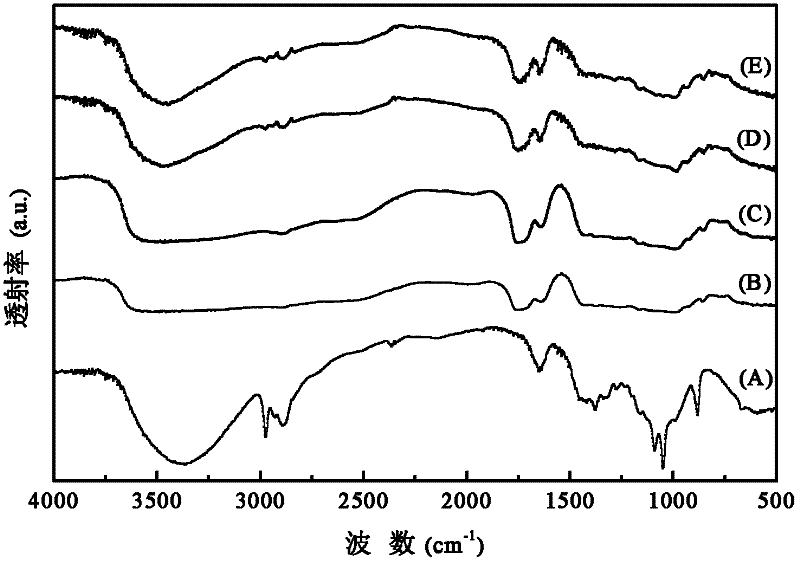

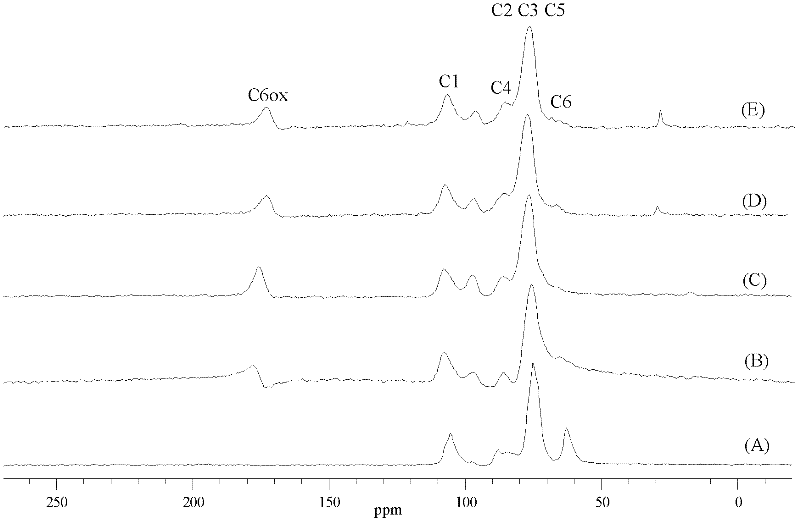

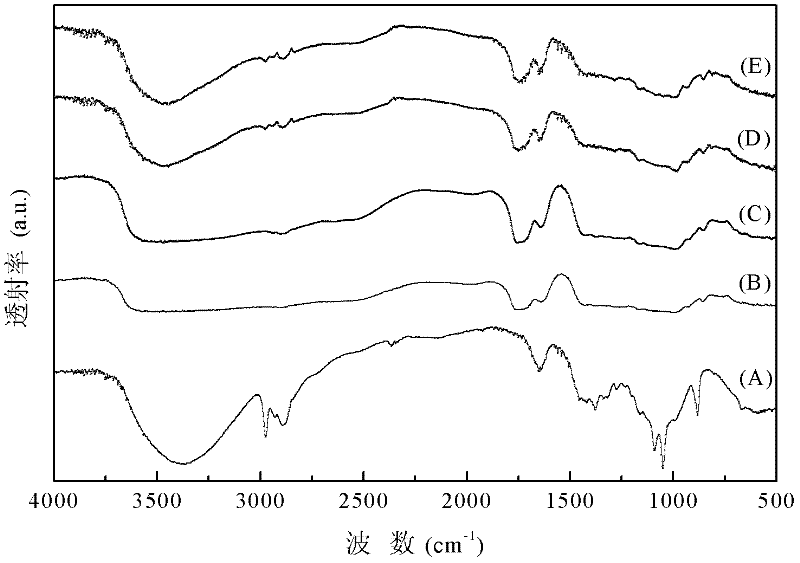

[0011] Specific Embodiment 1: The preparation method of the oxidized regenerated cellulose absorbable hemostatic material in this embodiment is carried out according to the following steps: 1. Nitrogen dioxide and cyclohexane are added to the circulating reactor to form an oxidizing liquid, and two in the oxidizing liquid The mass percent concentration of nitrogen oxide is 5% to 75%, and then regenerated cellulose is added to completely soak the regenerated cellulose in the oxidation solution, the reactor is sealed, and the reaction time is 1 to 72 hours at 5 to 45°C to obtain the oxidation product; 2. Rinse the oxidized product with cyclohexane for 2 to 5 times, then use an aqueous ethanol solution with a volume concentration of 20% to 95% to rinse the oxidized product 2 to 3 times, and then rinse the oxidized product with absolute ethanol for 3 to 5 times; 3. Then put the oxidized product rinsed with absolute ethanol at -80~-10℃ to freeze-dry for 24~72 hours to obtain the oxi...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the concentration of nitrogen dioxide in the oxidation solution in step 1 is 20%-50% by mass. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the degree of polymerization of the regenerated cellulose in step 1 is 100-500. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com