Method for promoting complex enzyme to catalyze degradation of straws by using active mediator combination

A technology of catalytic degradation and rice straw, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of small environmental pollution, large amount of acid and alkali, high energy consumption, etc., and achieve the purpose of improving the decay rate and operating costs Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

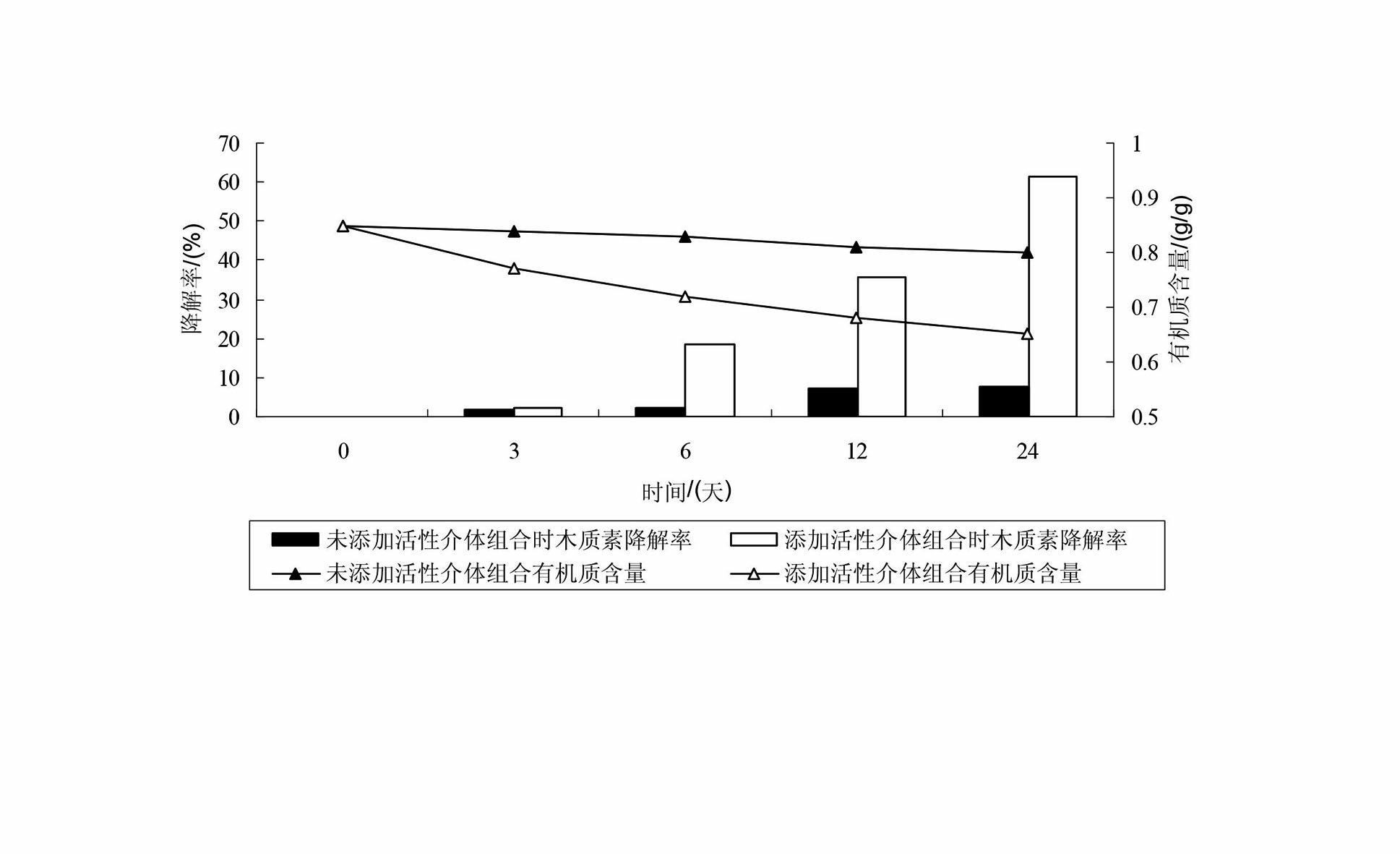

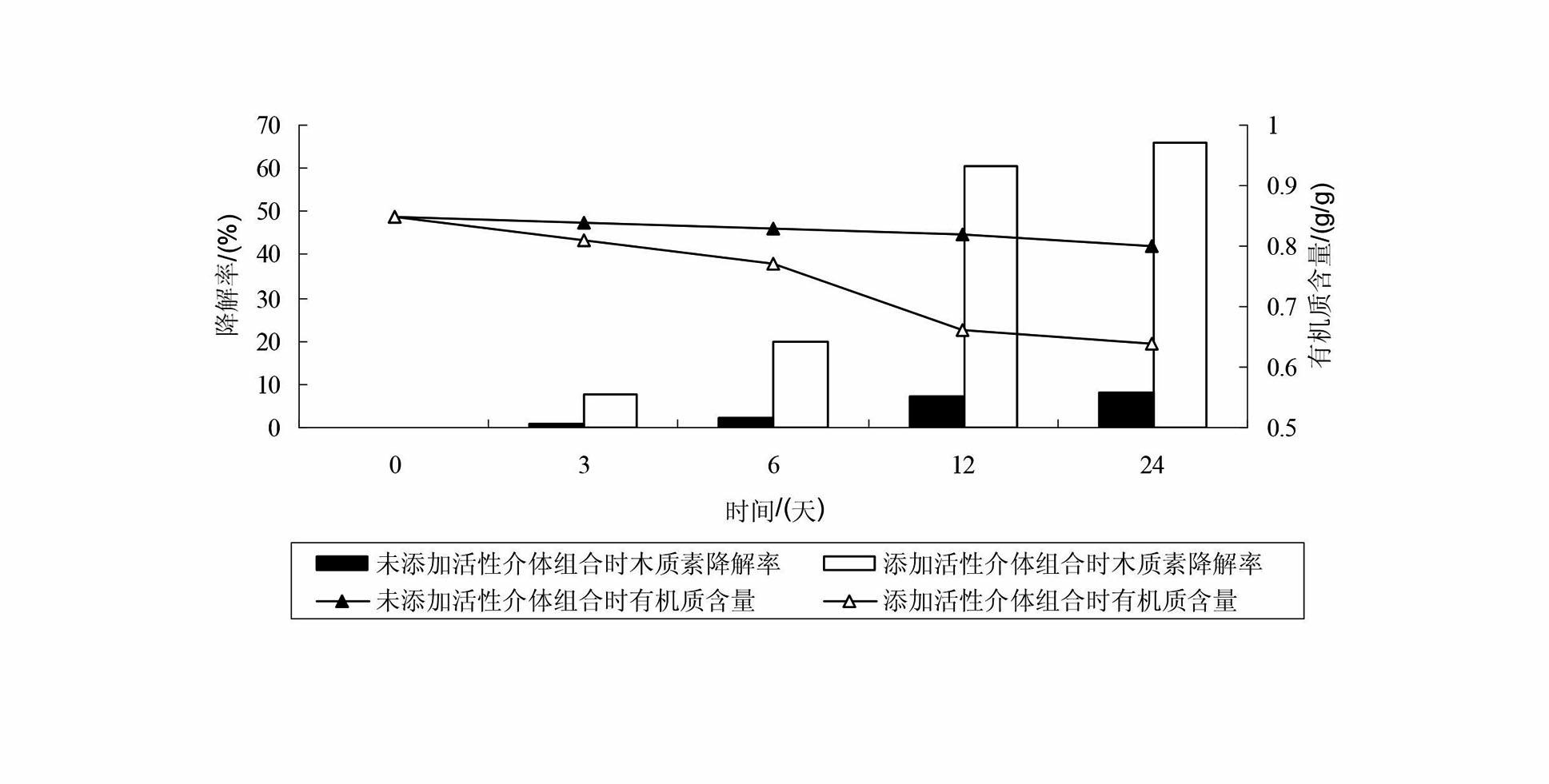

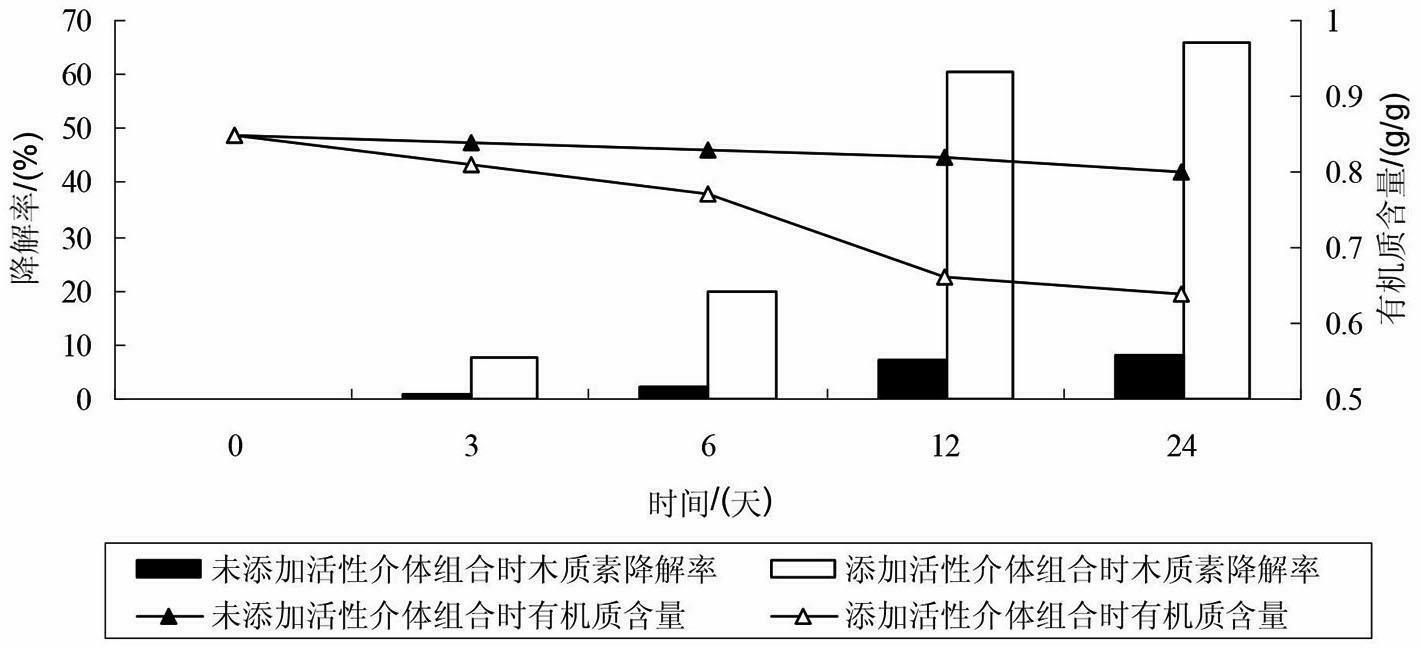

Image

Examples

Embodiment 1

[0023] A kind of method that utilizes active mediator combination of the present invention to promote composite enzyme to catalyze and degrade rice straw, comprises the following steps:

[0024] (1) Straw pretreatment: crush rice straw to obtain straw powder, pass through a 60-mesh sieve for later use;

[0025] (2) Preparation of compound enzyme solution: add 2 mL of spores to 200 mL of sterilized liquid medium, the concentration is 1.5×10 6 Phanerochaete chrysosporium spore suspension per mL, cultured with shaking at 30°C and 120 r / min for 6 days, and obtained compound enzyme solution (15 U / L LiP and 213 U / L MnP); the formula of liquid medium (1L) is: glucose 10 g, ammonium tartrate 0.2 g, MgSO 4 0.71 g, Tween 80 0.5 mL, KH 2 PO 4 2.56 g, VB 1 0.01 g, sodium tartrate buffer 4.616 g, trace element solution 100 mL, benzyl alcohol 0.516 mL, H 2 O 899.484 mL, pH adjusted to 4.5;

[0026] (3) Catalytic degradation: Add the compound enzyme solution obtained in step (2) to ...

Embodiment 2

[0034] A kind of method that utilizes active mediator combination of the present invention to promote composite enzyme to catalyze and degrade rice straw, comprises the following steps:

[0035] (1) Straw pretreatment: crush rice straw to obtain straw powder, pass through a 100-mesh sieve for later use;

[0036](2) Preparation of compound enzyme solution: Add 4 mL of spores to 200 mL of sterilized liquid medium (the formula of the liquid medium is the same as that in Example 1) with a concentration of 2×10 6 Phanerochaete chrysosporium spore suspension per mL, cultured with shaking at 37°C and 150r / min for 8 days, and obtained the compound enzyme solution (20 U / L by precipitation, filter paper filtration, high-speed centrifugation and 0.45mm filter membrane filtration) LiP and 250 U / L of MnP);

[0037] (3) Catalytic degradation: Add the compound enzyme solution obtained in step (2) to 5 kg of straw powder obtained in step (1), and at the same time add veratrol solution with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com