Method for preparing protein stuffing for tanning with chrome-containing scrap leather from tanning

A technology for skin slag and chromium waste is applied in the field of utilization of waste slag resources, which can solve problems such as unfavorable industrial production, difference in chromium content, and difficulty in stable use process, and achieve significant economic and social benefits, and the content of hexavalent chromium is low and good. The effect of the retanning filling function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Grind the chromium-containing waste skin slag of tanning, take 100g, soak 45 hours with 0.3wt% NaOH solution of 500ml, drain the water, put the above-mentioned pretreated chromium-containing waste skin In the reaction kettle of the reflux condenser, add 8g NaOH, then add 500ml water, hydrolyze at a temperature of 55°C for 18 hours, and obtain a viscous dark liquid; after cooling the collagen hydrolyzate, adjust the pH to 7 with hydrochloric acid, filter, Obtaining solid content is 10% hydrolyzate 520ml; Malonic acid, N-hydroxysuccinimide and dicyclohexyl carbodiimide are mixed in a molar ratio of 0.5: 2: 1, dissolved in dimethylformamide, and Continuous stirring and reaction at room temperature for 12 hours, filtration, and the filtrate was distilled under reduced pressure, crystallized, recrystallized, and vacuum-dried to obtain malonate-N-hydroxysuccinimide ester, and 0.104 g of malonate was added to the collagen hydrolyzate -N-hydroxysuccinimide ester was stirred and...

Embodiment 2

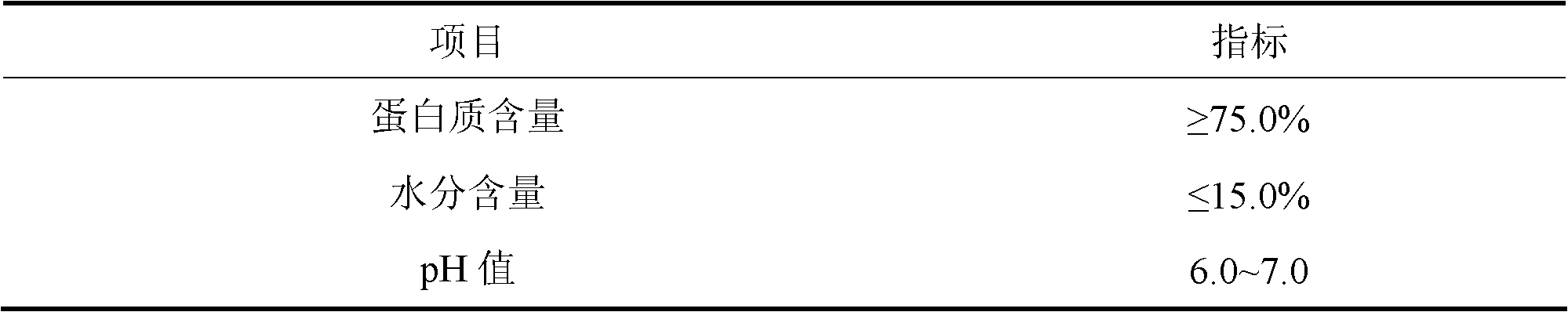

[0033] Grind the chromium-containing waste skin slag of tanning, get 100g, use 0.5wt%MgO and 0.5wt%Na of 400ml 2 CO 3 Soak the solution for 24 hours, drain the water, put the chromium-containing waste skin slag after the above pretreatment in a reaction kettle with a stirrer, a thermometer and a reflux condenser, add 5g MgO and 5g Na 2 CO 3 , add 400ml water again, hydrolyze at temperature 75 ℃ for 10 hours, obtain viscous shape dark liquid; Acid, N-hydroxysuccinimide and dicyclohexylcarbodiimide were mixed in a molar ratio of 0.5:1:2, dissolved in dimethylformamide, stirred continuously at room temperature for 24 hours, filtered, and the filtrate was decompressed Distillation, crystallization, recrystallization, and vacuum drying to obtain citric acid-N-hydroxysuccinimide ester, add 0.308g citric acid-N-hydroxysuccinimide ester to the collagen hydrolyzate, stir for 1 hour, concentrate and dry That is, the protein filler for tanning is obtained. The protein content of the ...

Embodiment 3

[0035] Grind the chromium-containing waste leather slag from tanning, get 100g, and use 450ml of 1.5wt%NaHCO 3 Soak in the solution for 15 hours, drain the water, put the chromium-containing waste skin slag after the above pretreatment into a reaction kettle with a stirrer, a thermometer and a reflux condenser, add 15g CaO, then add 450ml water, and heat the mixture at a temperature of 90°C Hydrolyzed for 3 hours to obtain viscous dark liquid; after cooling the hydrolyzed solution, adjust the pH to 6.5 with hydrochloric acid, filter to obtain 300ml of hydrolyzed solution with a solid content of 20%; mix malic acid, N-hydroxysuccinimide and Dicyclohexylcarbodiimide was mixed at a molar ratio of 1:2:1, dissolved in dimethylformamide, stirred continuously at room temperature for 18 hours, filtered, and the filtrate was distilled under reduced pressure, crystallized, recrystallized, and vacuum-dried To obtain malic acid-N-hydroxysuccinimide ester, add 0.3 g of malic acid-N-hydroxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com