High-flow dust particle counting sensor with novel photosensitive area structure

A dust particle counting and photosensitive area technology, applied in measurement devices, scientific instruments, individual particle analysis, etc., can solve the problems of fixed and unadjustable gas path position, impaired counting efficiency, and affected signal-to-noise ratio, etc., to reduce the probability of , reduce airflow resistance, reduce the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail and complete below in conjunction with the accompanying drawings.

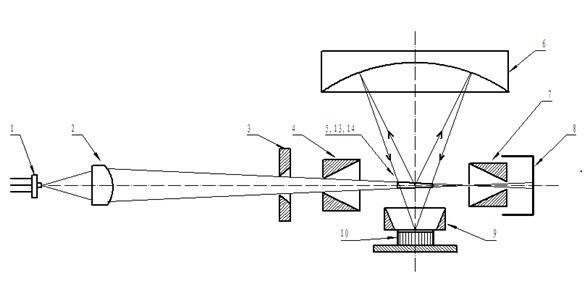

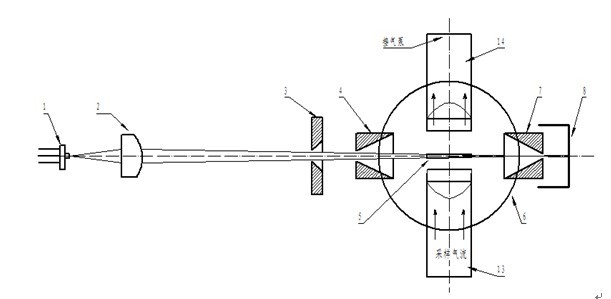

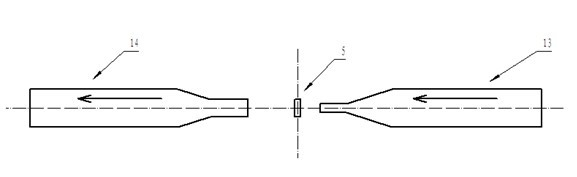

[0018] see figure 1 , figure 2 . figure 1 and figure 2 It is a structural schematic diagram of a large-flow dust particle counting sensor with a novel photosensitive area structure disclosed by the present invention. It can be seen that the present invention is a right-angle scattering optical system, including an illumination system, a scattered light collection system, and an air path system.

[0019] The lighting system consists of a semiconductor laser 1, an aspheric mirror 2, a first entrance aperture 3, a second entrance aperture 4, an exit aperture 7, and an optical trap 8, in which the first entrance aperture 3 and the second entrance aperture 4 are placed In front of the photosensitive area 5 , an exit diaphragm 7 is placed behind the photosensitive area 5 . Light source 1 adopts a high-power semiconductor laser light source great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com