Optical laminate and method for producing optical laminate

A manufacturing method and technology of optical layer, applied in chemical instruments and methods, optics, optical components, etc., can solve the problems of high manufacturing cost, high manufacturing cost, poor processing rationality, etc., to prevent durability deterioration, reduce manufacturing cost, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0171] Production Example 1 Preparation of Coating Liquid for Hard Coat

[0172] Compositions were prepared by thoroughly mixing the following materials. This composition was filtered with the polypropylene filter of 30 micrometers of pore diameters, and the coating liquid (1)-(3) for hard-coat layers was prepared.

[0173]

[0174] UV curable resin:

[0175] 91.9 parts by mass of pentaerythritol triacrylate (PETA)

[0176] Cellulose acetate propionate (molecular weight 50000) 1.2 parts by mass

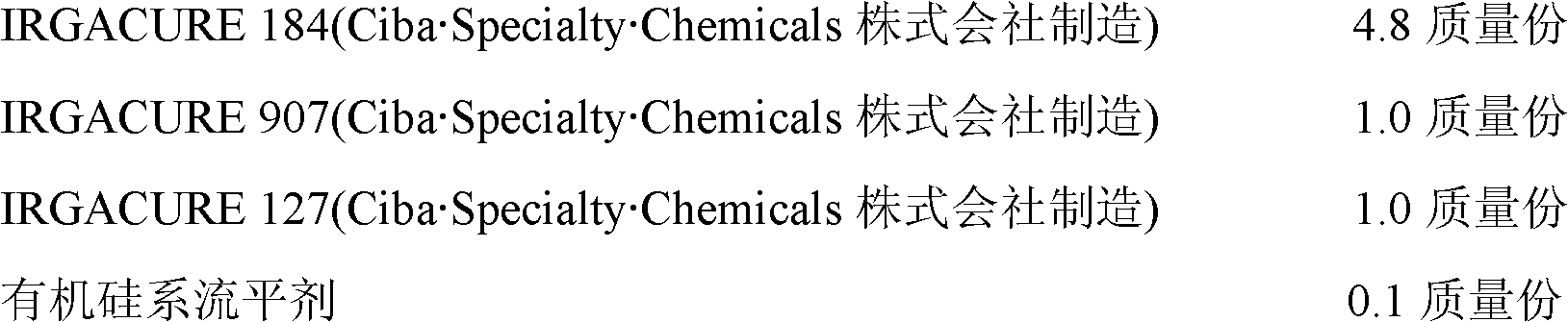

[0177] Photopolymerization initiator:

[0178]

[0179] Solvent:

[0180] 97.6 parts by mass of toluene

[0181] 24.4 parts by mass of methyl isobutyl ketone (MIBK)

[0182]

[0183] UV curable resin:

[0184] 43.1 parts by mass of pentaerythritol triacrylate (PETA)

[0185] Urethane acrylate (UV-1700B, manufactured by Nippon Synthetic Chemicals Co., Ltd.) 50.0 parts by mass

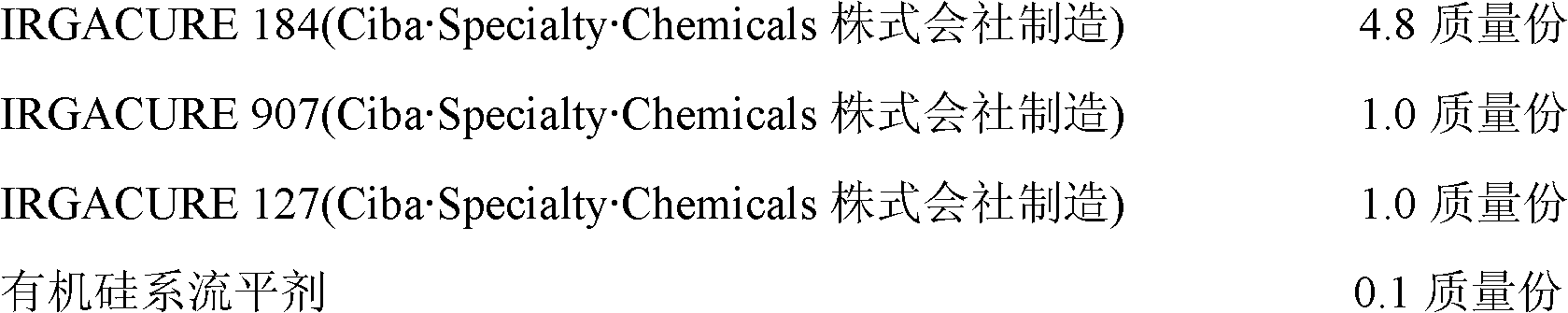

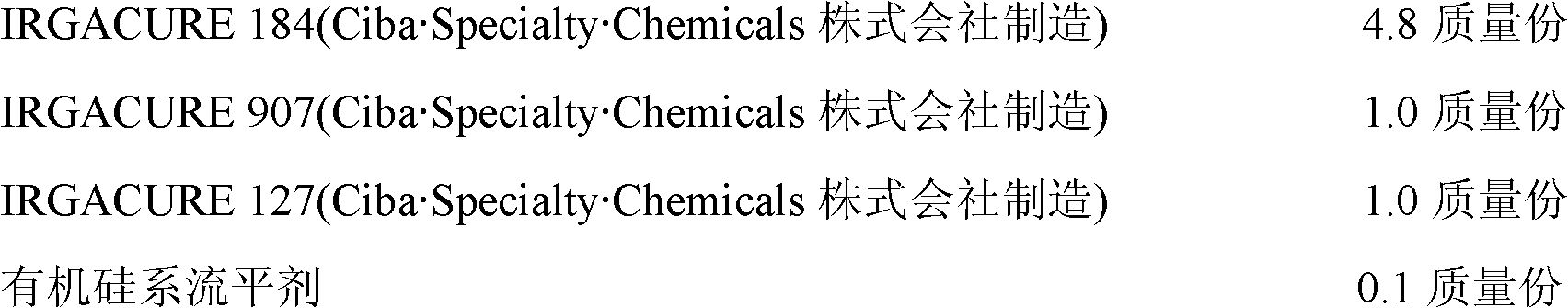

[0186] Photopolymerization initiator:

[0187]

[0188] Solvent:

[0189] 97.6 parts by...

manufacture example 2

[0200] Production Example 2 Preparation of UV Absorber

[0201] Each of the following ultraviolet absorbers was dissolved in a liquid of toluene / methyl isobutyl ketone = 70 / 30 (mass ratio) so as to be 45% by mass to prepare ultraviolet absorber liquids.

[0202] a-1) TINUVIN 478 (manufactured by Ciba Specialty Chemicals Co., Ltd., molecular weight: 678)

[0203] a-2) the compound of structural formula 1 (molecular weight is 736)

[0204] a-3) the compound of structural formula 2 (molecular weight is 680)

[0205] a-4) a compound with a weight average molecular weight of 25,000 obtained by the copolymerization of 65% by weight of the compound of structural formula 3 and 35% by weight of MMA (methyl methacrylate)

[0206] a-5) PUVA-30M (RUVA-93:MMA=30:70, weight average molecular weight is 10000)

[0207] a-6) the weight average molecular weight obtained by the compound of structural formula 4 of 65 mass % and the MMA copolymerization of 35 mass % is the compound of 20000 ...

Embodiment 1~17、 comparative example 1~10

[0216] A predetermined amount of the ultraviolet absorber liquid obtained in Production Example 2 was mixed with the coating liquid for a hard coat layer obtained in Production Example 1 to prepare a composition for a hard coat layer. Apply the obtained composition for a hard coat layer on a substrate, dry it with a warm air dryer at 70° C. for 1 minute, and then use a high-pressure mercury lamp under nitrogen purge (oxygen concentration is 200 ppm or less), using a lamp output A lamp manufactured by Fusion Corporation with a power of 240 W / cm was irradiated with ultraviolet light so that the output amount was adjusted so that the total irradiation amount became a predetermined amount in one irradiation, and an optical layered body having a hard coat layer was prepared.

[0217] In addition, the base material used, the coating liquid for hard-coat layers, ultraviolet absorber and its concentration, additives, lamp output, ultraviolet-ray irradiation amount, and the film thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com