Method for preparing light type chicken bouillon seasoning

A technology of seasoning and chicken sauce, which is applied in the field of preparation of soft chicken sauce seasoning, can solve the problems such as few reports, and achieve the effects of reducing economic loss, high efficiency and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

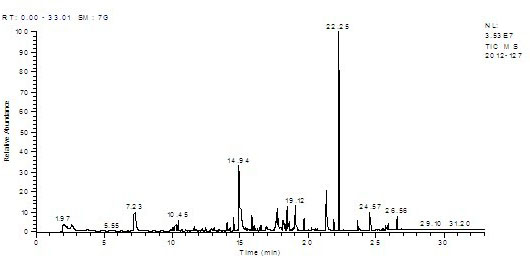

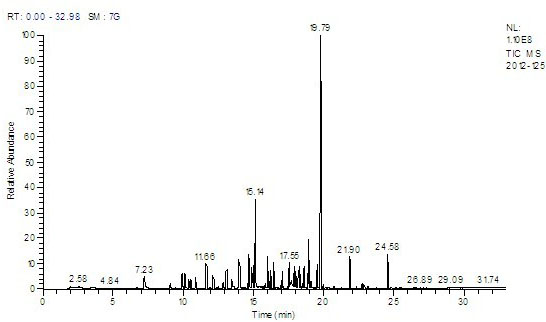

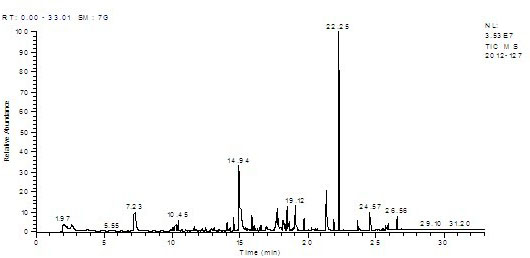

Image

Examples

Embodiment 1

[0041] Example 1: Enzymolysis of Chicken Skeleton to Prepare Soft Chicken Sauce Seasoning

[0042] Take 30 parts of fresh chicken breast, wash and add 60 parts of water, then add 8 parts of compound enzyme A (composite protease: flavor protease = 1:4), enzymolyze at 55°C and pH6 for 3 hours, and centrifuge the enzymatic solution Filter and take the supernatant as the raw material for heat reaction; take 30 parts of fresh chicken skeletons and put them in a high-pressure sterilizing pot for steaming at 120°C for 1 hour, then ultrafinely pulverize the chicken skeletons, add 30 parts of 20% ethanol, and add 8 parts Compound enzyme B (composite protease: papain = 1:2), enzymolysis at 55°C for 3 hours, inactivate the enzymolysis solution at 85-100°C, filter, and spray the obtained solution to remove alcohol and dehydration. To obtain the chicken skeleton protein polypeptide powder; add 0.5 part of chicken skeleton protein polypeptide powder, 3 parts of reducing sugar (glucose: xylo...

Embodiment 2

[0043] Example 2: Enzymolysis of Chicken Skeleton to Prepare Original Boiled Chicken Sauce Seasoning

[0044] Take 30 parts of fresh chicken breast, wash and add 40 parts of water, then add 6 parts of compound enzyme A (composite protease: flavor protease = 1:4), enzymolyze at 55°C and pH6.5 for 3 hours, and enzymolyze The liquid was centrifugally filtered, and the supernatant was taken as the heat reaction raw material; 30 parts of fresh chicken skeletons were taken, washed and added with 20 parts of water, put into an autoclave for cooking at 120°C for 30 minutes, and then the solid and liquid were separated, and the solid Superfine pulverization, add 30 parts of 20% ethanol, add 8 parts of compound enzyme B (composite protease: papain = 1:2), enzymolyze at 45°C for 4 hours, inactivate the enzymolyzed solution at 85-100°C , filter, obtain the described chicken skeleton protein polypeptide powder after spray drying, removing alcohol and dehydration of the gained solution; add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com