Magnetic permeating pot with flower-shaped hot-forged bottom covering piece and production method thereof

A production method, hot forging technology, applied in the field of electromagnetic cooker, can solve problems such as noise energy consumption, difficulty in deep drawing, deformation and polishing, and difficult welding process, so as to reduce the relative gap between thermal expansion and cold contraction, and improve induced current Skin effect, uniform distribution of induced current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] A method for processing an electromagnetic cooker with a flower-shaped hot forging and pressing bottom sheet, specifically comprising the following steps:

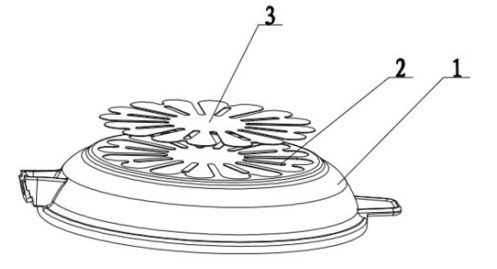

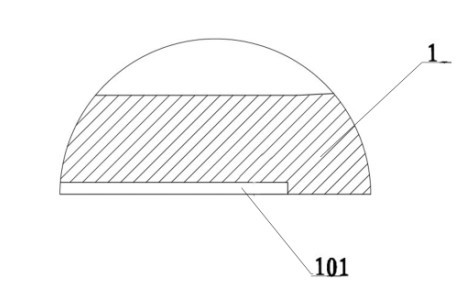

[0037]1) 430 stainless steel discs (thickness 0.5-0.7mm) are blanked and punched to form a steel-clad film 3 with the following structure: including a circular central body 301, and a group of heart-shaped petals are arranged around the circular central body 301 302 , a strip-shaped buffer groove I 303 is provided in the middle of the petal sheet 302 , and an outwardly opening buffer groove II 304 is arranged between the petal sheets 301 . The preferred structure is to set different numbers of petals 302 according to the diameter of the steel-clad base 3. When the diameter is less than 160 mm, seven petals 302 are set, and when the diameter is more than 160 mm, eight petals 302 are set. ,Such as Figure 6 shown;

[0038] 2) The steel-clad film 3 is degreased through the cleaning line, in order to clean the oil sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com