Catalyst for preparing 1, 4-cyclohexanedimethanol by catalyzing dimethyl terephthalate through one-step hydrogenation and preparation method of catalyst

A technology of dimethyl phthalate and cyclohexanedimethanol, which is applied in the field of catalyst preparation, can solve problems such as unfavorable energy resource consumption and complex process routes, and achieves avoidance of separation and solvent consumption, high product yield, and reduced The effect of consumption of energy resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] 0.13g RuCl 3 ·3H 2 O, 0.22g SnCl 2 2H 2 O and 0.096g H 2 PtCl 6 ·6H 2 Dissolve O in 2ml of deionized water, add 0.2ml of hydrochloric acid with a mass concentration of 35% until completely dissolved, then add 1g of Al with a particle size of 60-80 mesh 2 o 3 , aging at room temperature for 20 hours, drying in vacuum at 60°C for 12 hours, and then roasting in air at 450°C for 8 hours; then adding 20ml of water, adding 0.5g of sodium borohydride for reduction, after 2 hours until no obvious bubbles are released; finally in a nitrogen atmosphere at 70°C Dry in medium for 10h for later use.

[0010] The active components of the prepared catalyst, ruthenium, tin and platinum, were supported on the carrier Al 2 o 3 Above, wherein the mass percentage of ruthenium is 5%, the mass percentage of platinum is 3.2%, and the mass percentage of tin is 11.7%; the particle size of the catalyst is 60-80 mesh.

Embodiment 2

[0012] 0.13g RuCl 3 ·3H 2 O, 0.22g SnCl 2 2H 2 O and 0.13g H 2 PtCl 6 ·6H 2 Dissolve O in 2ml of deionized water, add 0.2ml of hydrochloric acid with a mass concentration of 35% until completely dissolved, then add 1g of Al with a particle size of 40-60 mesh 2 o 3 , aging at room temperature for 20 hours, drying in vacuum at 60°C for 12 hours, and then roasting in air at 450°C for 8 hours; then adding 20ml of water, adding 0.5g of sodium borohydride for reduction, after 2 hours until no obvious bubbles are released; finally in a nitrogen atmosphere at 70°C Dry in medium for 10h for later use.

[0013] The active components of the prepared catalyst, ruthenium, tin and platinum, were supported on the carrier Al 2 o 3 Above, the mass percentage of ruthenium is 5%, the mass percentage of platinum is 4.8%, and the mass percentage of tin is 11.7%; the particle size of the catalyst is 40-60 mesh.

Embodiment 3

[0015] 0.13g RuCl 3 ·3H 2 O, 0.22g SnCl 2 2H 2 O and 0.19g H 2 PtCl 6 ·6H 2 Dissolve O in 2ml of deionized water, add O.2ml of hydrochloric acid with a mass concentration of 35% until completely dissolved, then add 1g of Al with a particle size of 40-80 mesh 2 o 3 , aging at room temperature for 20 hours, drying in vacuum at 60°C for 12 hours, and then roasting in air at 450°C for 8 hours; then adding 20ml of water, adding 0.5g of sodium borohydride for reduction, after 2 hours until no obvious bubbles are released; finally in a nitrogen atmosphere at 70°C Dry in medium for 10h for later use.

[0016] The active components of the prepared catalyst, ruthenium, tin and platinum, were supported on the carrier Al 2 o 3 Above, the mass percentage of ruthenium is 5%, the mass percentage of platinum is 7.2%, and the mass percentage of tin is 11.7%; the particle size of the catalyst is 40-80 mesh.

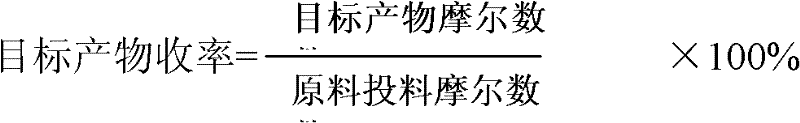

[0017] The catalysts prepared in the above examples 1, 2, and 3 were applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com