Hydrothermal method for preparing graphene

A graphene and hydrothermal technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of high environmental pollution, small output, high cost, etc., and achieve the effect of easy-to-obtain raw materials and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Natural flake graphite is prepared into expanded graphite (EG) by oxidative intercalation, and 0.1g of EG is weighed and immersed in 15mL, 0.5mol / L calcium chloride solution for 0.5h to obtain EG suspension solution (a); prepare 0.2mol 15 mL of urea solution per L was slowly added dropwise to the EG suspension solution (a) while stirring, and stood at room temperature for 3 hours to obtain the EG suspension solution (b); In a reaction kettle with ethylene as the substrate, react at 80°C for 10h; after the reaction, vacuum filter the product, wash it with deionized water until neutral, and dry it in vacuum at 20°C; disperse the product in absolute ethanol , ultrasonication for 0.5h to obtain a stable dispersion, vacuum filtration, washing with deionized water, and vacuum drying at 20°C to obtain graphene.

Embodiment 2

[0017] Natural flake graphite was prepared into expanded graphite (EG) by oxidative intercalation. Weighed 0.2g of EG and impregnated it into 15mL, 0.5mol / L calcium chloride solution for 1h to obtain EG suspension solution (a); prepared 1mol / L 15mL of urea solution, slowly added dropwise to the EG suspension solution (a) while stirring, and left to stand at room temperature for 6h to obtain the EG suspension solution (b); In the reaction kettle of the substrate, react at 100°C for 16h; after the reaction, vacuum filter the product, wash it with deionized water until neutral, and dry it in vacuum at 60°C; disperse the product in absolute ethanol, Ultrasound for 1 hour to obtain a stable dispersion, vacuum filtration, washing with deionized water, and vacuum drying at 60°C to obtain graphene.

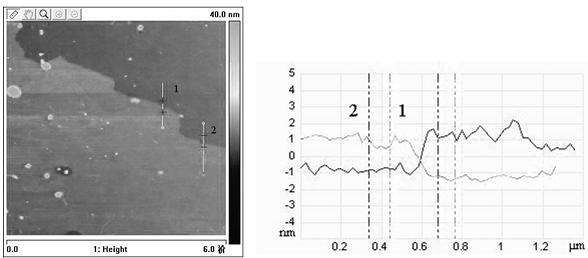

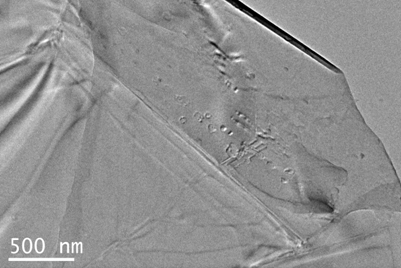

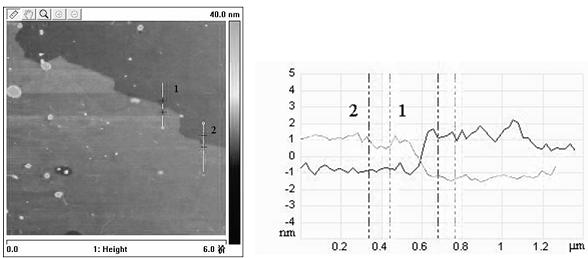

[0018] figure 1 For the graphene AFM figure that embodiment 2 makes, figure 1 It can be seen that the thickness of graphene is about 2nm. Since the edge of graphene is warped and wrinkl...

specific Embodiment 3

[0020] Natural flake graphite was prepared into expanded graphite (EG) by oxidative intercalation, and 1g of EG was weighed and immersed in 15mL, 0.5mol / L calcium chloride solution for 1.5h to obtain EG suspension solution (a); prepared 1.6mol / L 15 mL of urea solution in L was slowly added dropwise to the EG suspension solution (a) while stirring, and stood at room temperature for 8 hours to obtain the EG suspension solution (b); In a reaction kettle with a substrate as the substrate, react at 150°C for 20h; after the reaction, vacuum filter the product, wash it with deionized water until neutral, and dry it in vacuum at 80°C; disperse the product in absolute ethanol , sonicated for 3 hours to obtain a stable dispersion, vacuum-filtered, washed with deionized water, and vacuum-dried at 80°C to obtain graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com