Industrial method for producing battery-grade lithium carbonate or high-purity lithium carbonate

A technology of high-purity lithium carbonate and lithium carbonate, which is applied in the direction of lithium carbonate; The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

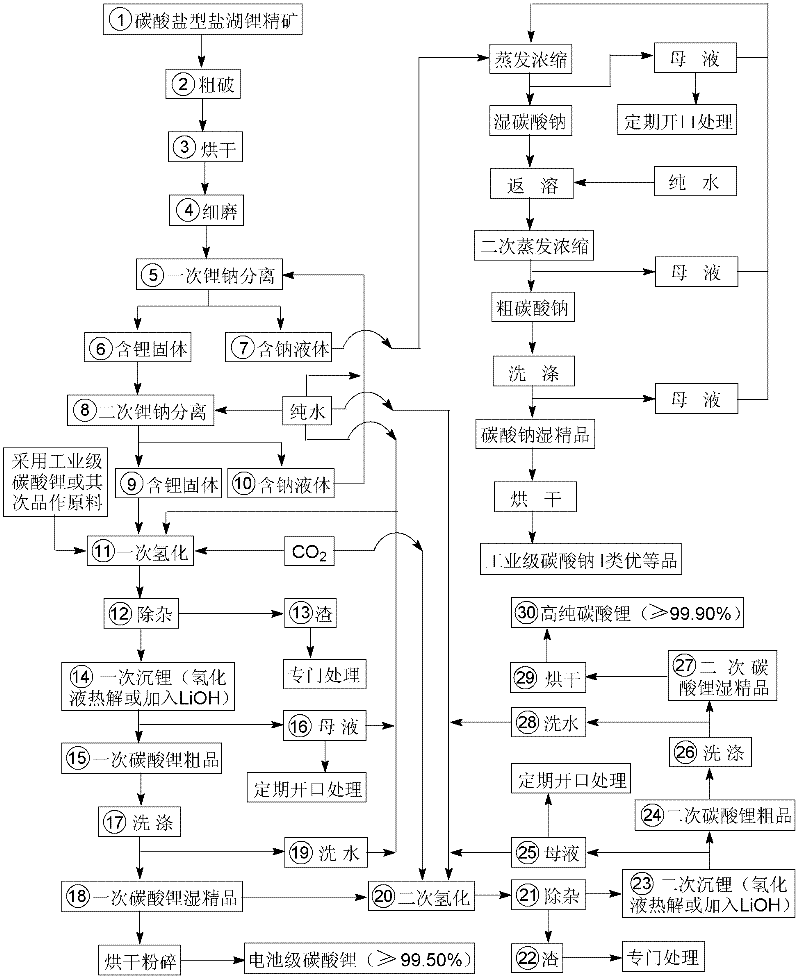

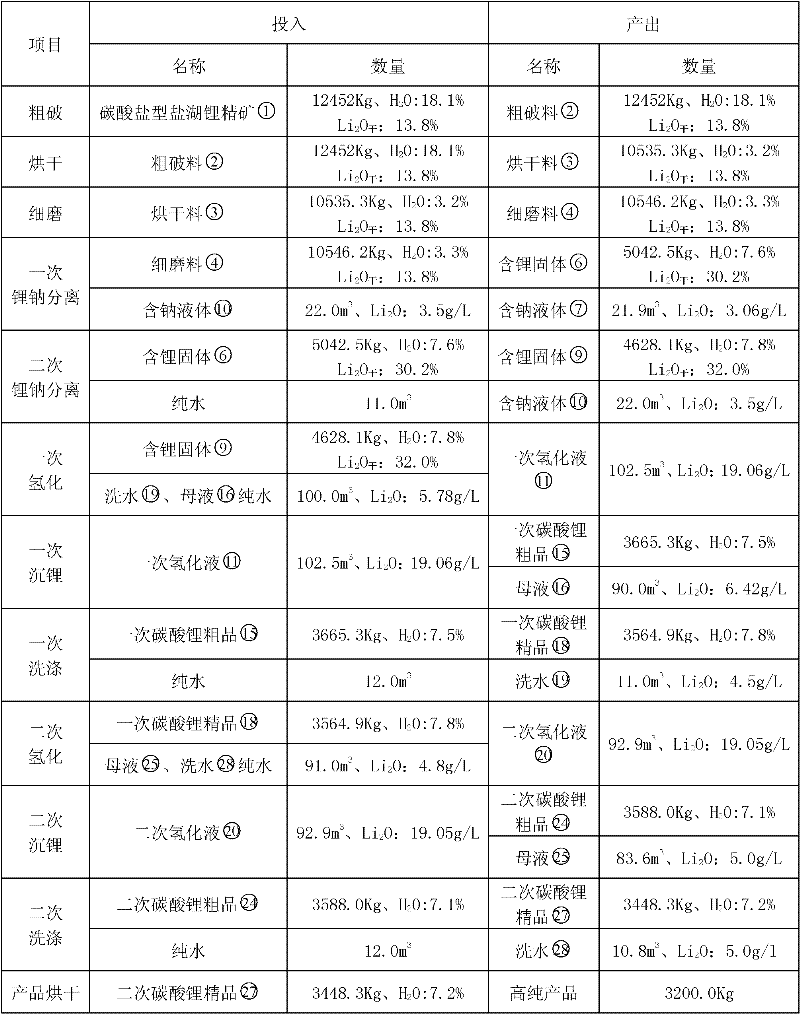

[0054] Embodiment 1 adopts the industrialized method of directly producing battery-grade lithium carbonate by carbonate type salt lake lithium concentrate

[0055] according to figure 1 Shown technological process, prepares battery-grade lithium carbonate:

[0056] (1), grinding

[0057] ① Take carbonate-type salt lake lithium concentrate (such as Tibetan carbonate-type salt lake lithium concentrate). This type of lithium concentrate can be obtained through purchase, or can be obtained by extracting lithium resources in salt lake brine by conventional processes.

[0058] The chemical composition of the lithium ore:

[0059] Li 2 O: 10.0-30.0% Na + : 5.0~16.5%K + : 2.6~4.0%

[0060] CO 3 2- : 8.0~56.0% Cl - : 8.0~11.0% SO 4 2- : 1.5~4.0%

[0061] Ca 2+ : 0.4~1.5% Mg 2+ : 0.4~5.0%

[0062] ②coarse crushing: directly crush the material with a particle size of ≤5mm;

[0063] ③Drying Drying temperature≤350℃, material moisture≤3%;

[0064] ④Fine Grinding Use ultra-...

Embodiment 2

[0096] Embodiment 2 adopts the industrialized method of carbonate type salt lake lithium concentrate to directly produce high-purity lithium carbonate

[0097] With reference to the method of Example 1, first prepare a Li 2 CO 3 wet boutique Then carry out the second carbonization, the steps are as follows:

[0098] 1. Secondary carbonization

[0099] Secondary hydrogenation to take Li once 2 CO 3 wet boutique Add pure water, Li 2 CO 3 mother liquor or washing water The secondary hydrogenation is carried out in one or several mixed liquids, the specific method and conditions are the same as the primary hydrogenation

[0100] Secondary impurity removal Add lithium salt of ethylenediaminetetraacetate, oxalic acid, lithium oxalate, phosphoric acid, lithium phosphate, lithium dihydrogen phosphate, etc. for impurity removal, filtration, precipitation Mainly incompletely reacted Li 2 CO 3 And a small amount of slag left by the impurity removal, the precipitat...

Embodiment 3

[0116] Embodiment 3 adopts technical grade lithium carbonate or its product to prepare the industrialized method of battery grade lithium carbonate

[0117] according to figure 1 Shown technological process, prepares battery-grade lithium carbonate:

[0118] 1 primary carbonization

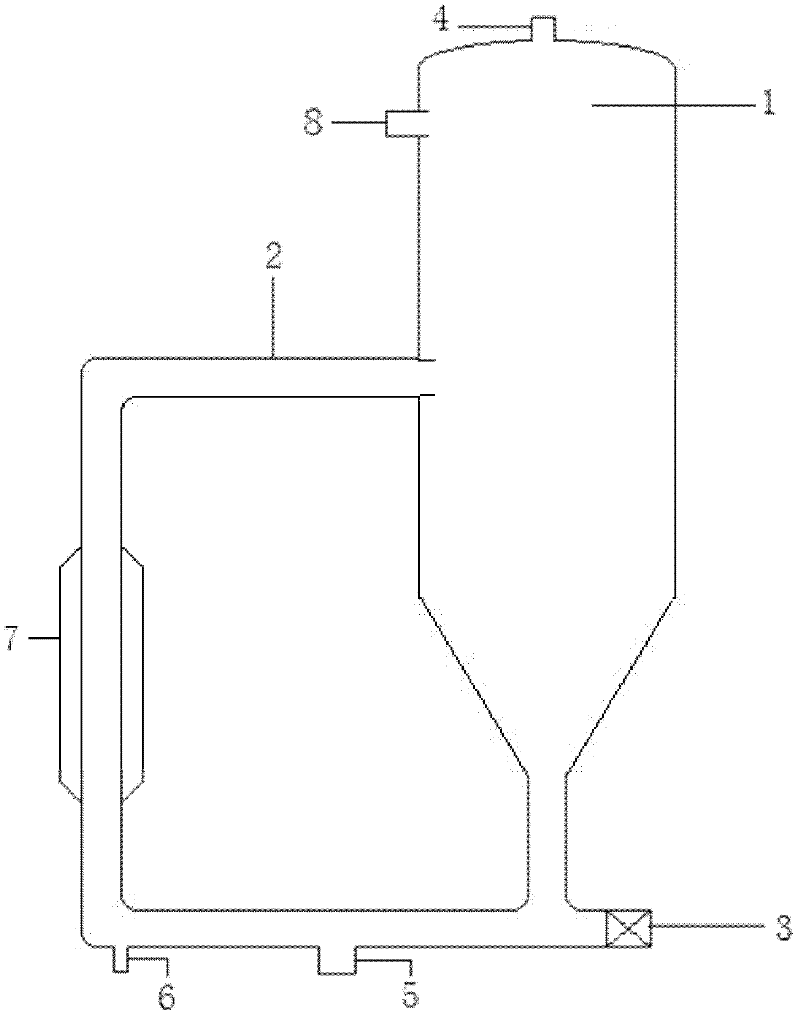

[0119] Primary hydrogenation: get technical grade lithium carbonate or its product (Li 2 O: 38.0~40.3%), add pure water, Li 2CO 3 wash water or Li 2 CO 3 mother liquor In one or several mixed liquids, the feeding amount of lithium-containing solid ⑨ is 3000kg~6000kg, and the amount of liquid added is 50~100m 3 , in the hydrogenation reactor provided by the present invention (the hydrogenation reactor sees embodiment 3), airtightly feeds CO 2 , the temperature is ≤25°C, the time is 1~2h, the pressure is 0.2~0.3MPa, the end point is based on the pH of the hydrogenation solution 7.0~8.5, the flow rate of the material in the circulation pipe is 3~5m / s, and each kettle can prepare hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com