Industrial method for producing battery-grade lithium carbonate or high-purity lithium carbonate

A technology of high-purity lithium carbonate and lithium carbonate, which is applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of inapplicability to large-scale industrial production, achieve good market application prospects, reduce consumption, and save water rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

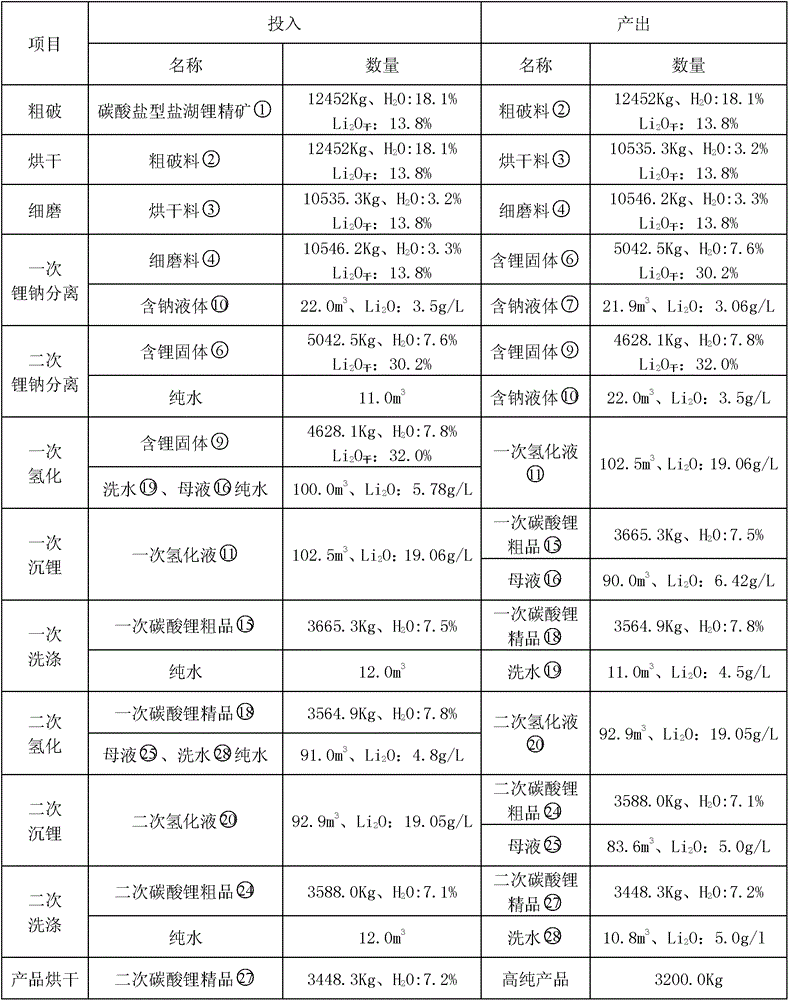

[0054] Example 1 Industrialized method for directly producing battery-grade lithium carbonate using carbonate-type salt lake lithium concentrate

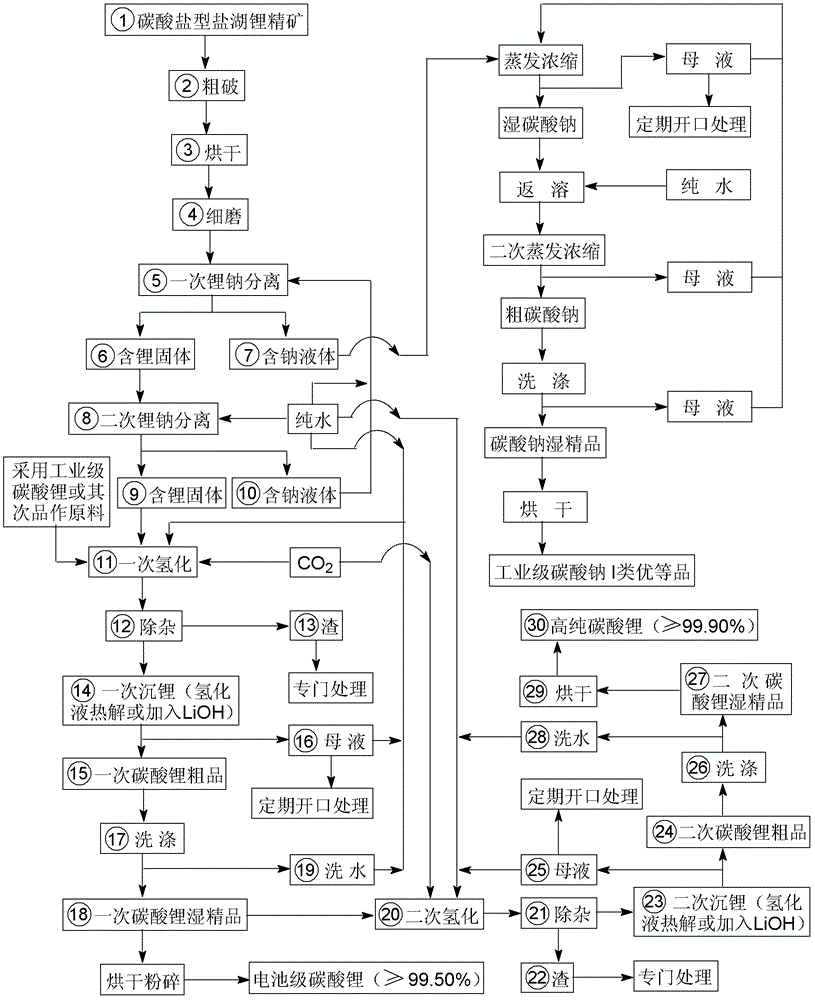

[0055] According to figure 1 The process flow shown to prepare battery-grade lithium carbonate:

[0056] (1), ground

[0057] ① Take carbonate type salt lake lithium concentrate (such as Tibet carbonate type salt lake lithium concentrate). This type of lithium concentrate can be obtained through purchase, or can be obtained by extracting lithium resources from salt lake brine using conventional processes.

[0058] The chemical composition of the lithium mine:

[0059] Li 2 O: 10.0~30.0% Na + :5.0~16.5% K + :2.6~4.0%

[0060] CO 3 2- :8.0~56.0% Cl - :8.0~11.0% SO 4 2- :1.5~4.0%

[0061] Ca 2+ :0.4~1.5% Mg 2+ :0.4~5.0%

[0062] ②Coarse crushing Direct crushing of materials with particle size ≤5mm;

[0063] ③Drying The drying temperature is ≤350℃, and the moisture content of the material is ≤3%;

Embodiment 2

[0096] Example 2 Industrialized method for directly producing high-purity lithium carbonate using carbonate-type salt lake lithium concentrate

[0097] With reference to the method in Example 1, first prepare Li 2 CO 3 Wet boutique Carry out the second carbonization, the steps are as follows:

[0098] 1. Secondary carbonization

[0099] Secondary hydrogenation, take primary Li 2 CO 3 Wet boutique Add pure water, Li 2 CO 3 Mother liquor Or wash The second hydrogenation is carried out in one or several mixed liquids, and the specific methods and conditions are the same as that of the primary hydrogenation

[0100] Secondary impurity removal Add ethylenediaminetetraacetate lithium salt, oxalic acid, lithium oxalate, phosphoric acid, lithium phosphate, lithium dihydrogen phosphate, etc. for impurity removal and filtration, precipitation Mainly incompletely reacted Li 2 CO 3 And a small amount of slag left by the removal of impurities, the precipitation It is used for special treat...

Embodiment 3

[0116] Example 3 Industrialized method for preparing battery-grade lithium carbonate using industrial-grade lithium carbonate or its inferior products

[0117] According to figure 1 The process flow shown to prepare battery-grade lithium carbonate:

[0118] 1 carbonization

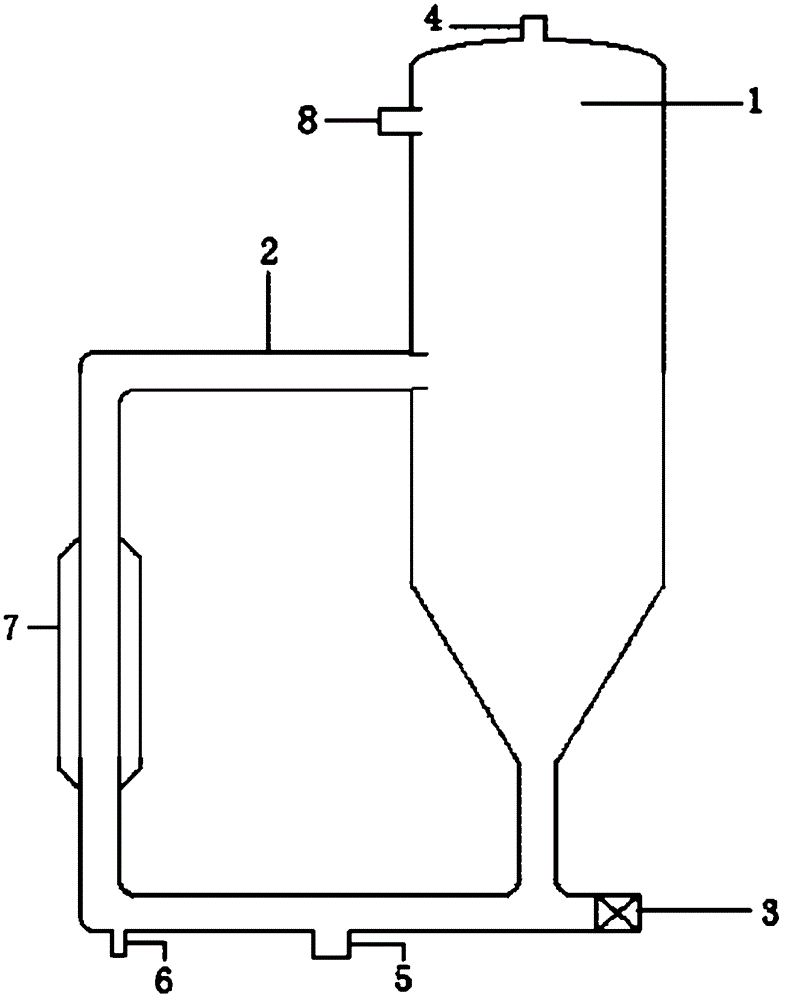

[0119] One-time hydrogenation to take industrial grade lithium carbonate or its inferior product (Li 2 O: 38.0~40.3%), add pure water and Li 2 CO 3 Wash water Or Li 2 CO 3 Mother liquor In one or several mixed liquids, the lithium-containing solid ⑨ dosage is 3000kg~6000kg, and the liquid dosage is 50~100m 3 In the hydrogenation reactor provided by the present invention (see Example 3 for the hydrogenation reactor), CO 2 , Temperature≤25℃, time is 1~2h, pressure is 0.2~0.3MPa, the end point is hydrogenated liquid pH 7.0~8.5, the flow rate of the material in the circulation pipe is 3~5m / s, each kettle can prepare hydrogenation liquid 50~ 100m 3 .

[0120] Impurity removal After hydrogenation treatment, add oxal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com