Method for treating antibiotic wastewater

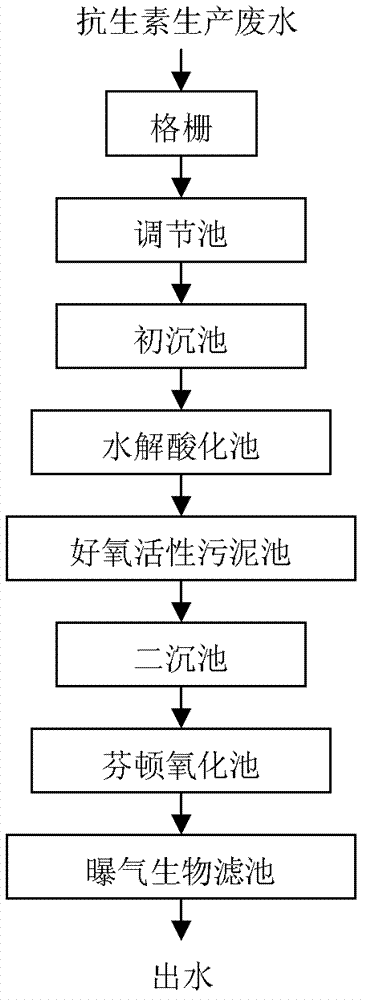

A treatment method and antibiotic technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Secondary pollution and other problems, to achieve the effect of reducing unit treatment energy consumption, safe and stable effluent quality, and low infrastructure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

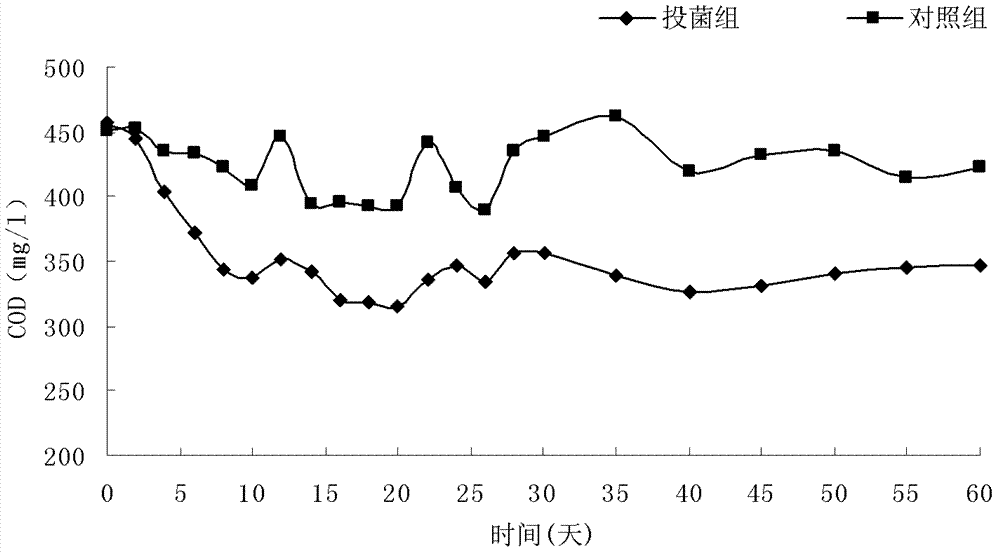

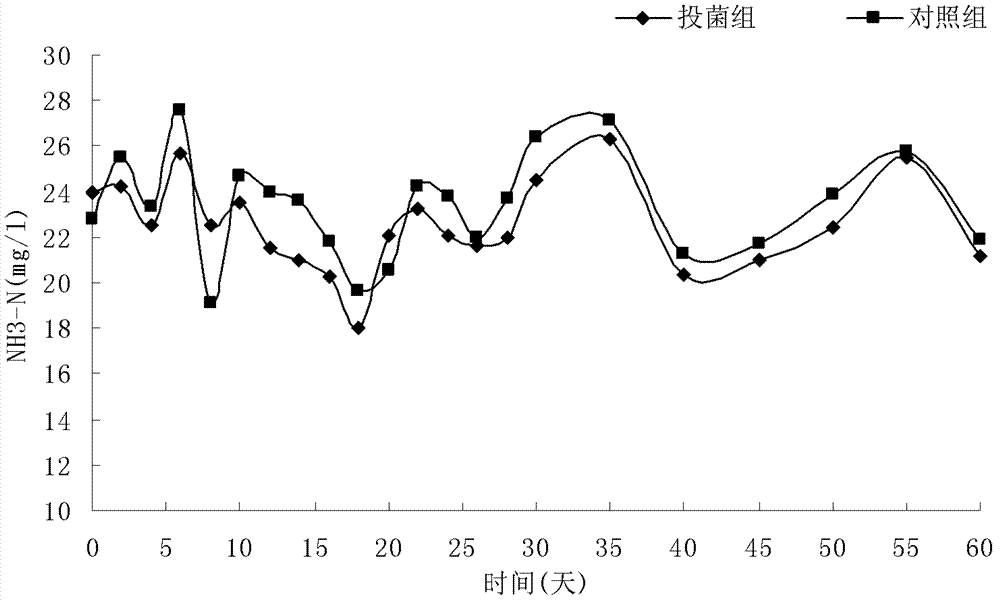

[0028] Embodiment 1: comparative test in the aerobic activated sludge tank after the hydrolytic acidification treatment of erythromycin production wastewater

[0029] The erythromycin production wastewater after hydrolysis and acidification treatment was divided into two groups, one of which was the control group, in which no reagents or strains were added except for the aerobic activated sludge, and the other group was the bacterial injection group, except the well Microbial agents were added to the oxygen-activated sludge every day. In the two groups of experiments, after 24 hours of aeration reaction, the supernatant in the tank was discharged after half an hour of settlement, and the wastewater from the hydrolytic acidification tank was added again. In the two groups of experiments, the pH value of the wastewater was adjusted to 8.0, and the dissolved oxygen was 3mg / l. The initial dosage of the microbial agent in the bacterial injection group was 10‰ (volume ratio), and the...

Embodiment 2

[0031] Embodiment 2: the pilot test of method of the present invention processing penicillin production wastewater

[0032] The wastewater from the penicillin production wastewater pretreatment of Shandong New Times Pharmaceutical Co., Ltd. was used for the pilot test. During the test, the wastewater stayed in the hydrolytic acidification tank for 60 hours, the pH value was 7.0, and the dissolved oxygen was 0.3mg / l; The residence time in the activated sludge tank is 10h, the pH value is 8.0, the dissolved oxygen is 3mg / l, the initial dosage of microbial agent is 10‰ (volume ratio), and after two weeks of continuous dosage, the dosage is 0.5‰ (volume ratio ), continue to add COD and NH in the effluent for six weeks 3 -N and penicillin concentrations were basically stable and stopped adding; the pH value of the wastewater in the Fenton oxidation pond was 3.0, Fe 2+ Mass concentration 10mg / l, H 2 o 2 The total mass concentration is 120mg / l, and it is added evenly in three time...

Embodiment 3

[0034] Embodiment 3: the pilot test of method of the present invention processing erythromycin production waste water

[0035] The wastewater from Shandong New Times Pharmaceutical Co., Ltd. after pretreatment of erythromycin production wastewater was used for a pilot test. During the test, the wastewater stayed in the hydrolytic acidification tank for 48 hours, the pH value was 6.5, and the dissolved oxygen was 0.5mg / l; The residence time in the aerobic activated sludge tank is 10h, the pH value is 8.0, the dissolved oxygen is 4mg / l, the initial dosage of microbial agent is 15‰ (volume ratio), and the dosage after continuous dosage is 1‰ (volume ratio) ratio), continue to add COD and NH in the effluent for four weeks 3 -N and erythromycin concentrations were basically stable and stopped adding; the pH value of the wastewater in the Fenton oxidation pond was 3.0, Fe 2+ Mass concentration 15mg / l, H 2 o 2 The total mass concentration is 150mg / l, and it is added evenly in thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com