Anti-ferroelectric thick film with high breakdown field strength and preparation method

An antiferroelectric, high breakdown technology, applied in lead zirconate-based antiferroelectric thick film and its preparation, development and application of high power and large capacity storage capacitor devices, can solve the problem of poor compactness, high energy loss, breakdown Solve the problems of low breakdown electric field and saturation polarization, and achieve the effect of high breakdown electric field and high saturation polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

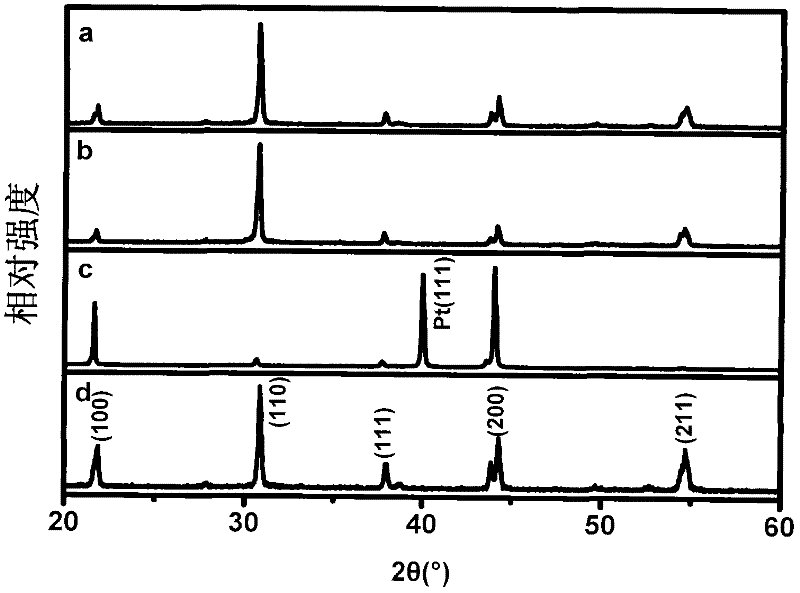

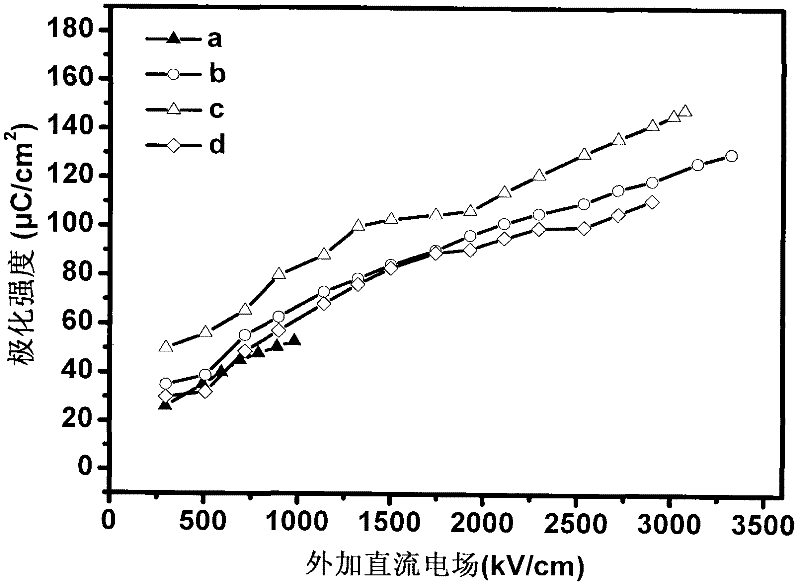

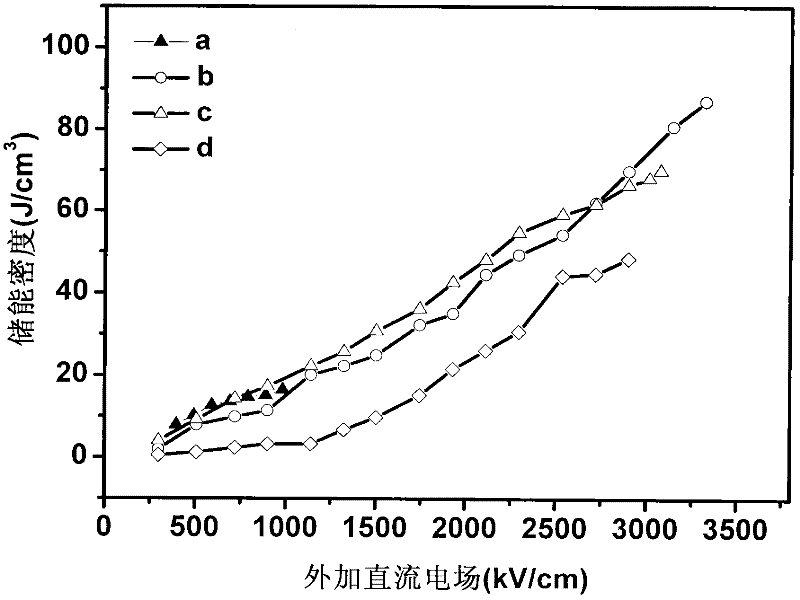

Embodiment 1

[0023] 1. The electrode is LaNiO 3 electrode;

[0024] 2. (Pb 0.97 La 0.02 )(Zr 080 sn 0.18 Ti 0.02 )O 3 Preparation of antiferroelectric thick film

[0025] 1)(Pb 0.97 La 0.02 )(Zr 0.80 sn 0.18 Ti 0.02 )O 3 Preparation of precursor solution

[0026] Lead acetate, lanthanum acetate, tin acetate, titanium isopropoxide and zirconium n-propoxide are used as raw materials, the solvent is glacial acetic acid and water, and the film-forming aid is polyvinylpyrrolidone PVP. Lead acetate [Pb(CH 3 COO) 2 ], lanthanum acetate [La(CH 3 COO) 3 ] and tin acetate [Sn(CH 3 COO) 4 ] According to the stoichiometry of 97:2:18 in the mol ratio of lead, lanthanum, tin, be heated to boiling in glacial acetic acid solution for 10 minutes, after cooling to room temperature, make solution a; Then add in the solution a that makes Zirconium n-propoxide [Zr(OC 3 h 7 ) 4 ] and titanium isopropoxide [Ti[OCH(CH 3 ) 2 ] 4 ], make the mol ratio of lead, zirconium, titanium be 97:80:...

Embodiment 2

[0034] 1. The electrode is LaNiO 3 electrode;

[0035] 2. (Pb 0.97 La 0.02 )(Zr 098 Ti 0.02 )O 3 Preparation of antiferroelectric thick film

[0036] 1)(Pb 0.97 La 0.02 )(Zr 098 Ti 0.02 )O 3 Preparation of precursor solution

[0037] Lead acetate, lanthanum acetate, titanium isopropoxide and zirconium n-propoxide are used as raw materials, the solvent is glacial acetic acid and water, and the film-forming aid is polyvinylpyrrolidone PVP. Lead acetate [Pb(CH 3 COO) 2 ] and lanthanum acetate [La(CH 3 COO) 3 ] According to the molar ratio of 97:2, it was heated in glacial acetic acid solution for 20 minutes, and then cooled to room temperature to obtain solution a. Then zirconium n-propoxide [Zr(OC 3 h 7 ) 4 ] and titanium isopropoxide [Ti[OCH(CH 3 ) 2 ] 4 ] join in the solution a, make the mol ratio of lead, zirconium, titanium be 97:98:2, add the deionized water simultaneously, make the mol ratio of deionized water and lead be 30:1, make solution b; In th...

Embodiment 3

[0045] 1. The bottom electrode is Pt electrode;

[0046] 2. Pb(Zr 087 sn 0.1 Ti 0.03 )O 3 Preparation of antiferroelectric thick film

[0047] 1)Pb(Zr 087 sn 0.1 Ti 0.03 )O 3 Preparation of precursor solution

[0048] Lead acetate, tin acetate, titanium isopropoxide and zirconium n-propoxide are used as raw materials, the solvent is glacial acetic acid and water, and the film-forming aid is polyvinylpyrrolidone PVP. Lead acetate [Pb(CH 3 COO) 2 ] and tin acetate [Sn(CH 3 COO) 4 ] According to the stoichiometric ratio of 100:10, the molar ratio of lead and tin was heated to boiling in glacial acetic acid solution for 20 minutes, and then cooled to room temperature to obtain solution a; then zirconium n-propoxide [Zr(OC 3 h 7 ) 4 ] and titanium isopropoxide [Ti[OCH(CH 3 ) 2 ] 4 ] was added to solution a, so that the molar ratio of lead, zirconium and titanium was 100:87:3, and a certain amount of deionized water was added at the same time, so that the molar rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com