Method for preparing hexagonal phase aluminum nitride nanofiber by using electrostatic spinning and ammonia nitridation

An electrospinning, phase aluminum nitride technology is applied in the field of electrospinning combined with ammonia nitridation to prepare hexagonal aluminum nitride nanofibers, which can solve the problems of complex post-processing process and high reaction temperature, and achieves low cost of raw materials, The effect of reducing the reaction temperature and simplifying the production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 3ml of deionized water and 7ml of absolute ethanol and mix evenly; dissolve 0.75g of aluminum nitrate in the hydroalcoholic solution; then add 1.05g of polyvinylpyrrolidone (number average molecular weight 1300000) to the above solution, and stir until the solution becomes clear transparent.

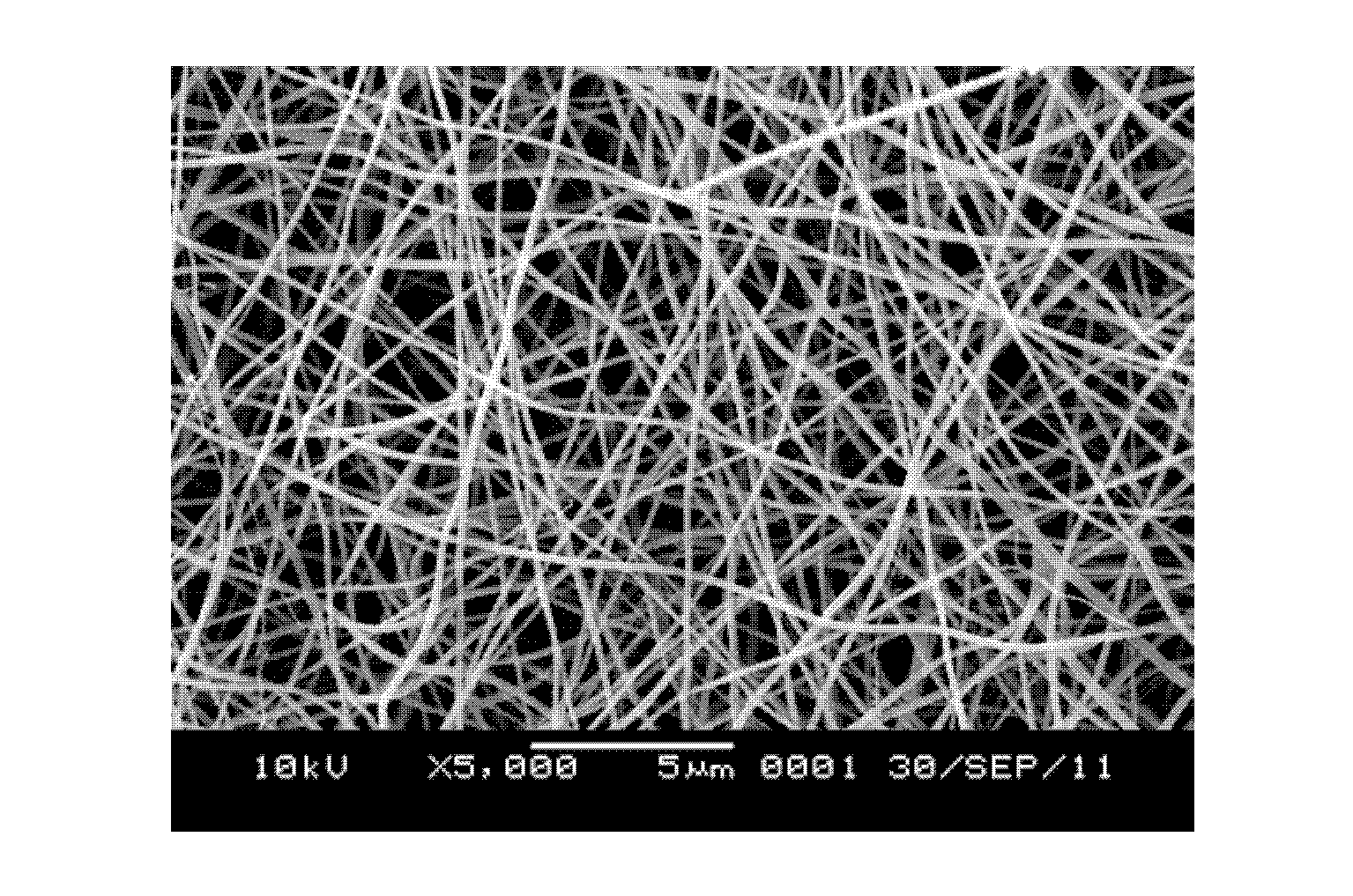

[0038] The obtained precursor solution was electrospun: at room temperature, the humidity was controlled at 25%, the spinning voltage was set to 10kv, the propulsion speed of the propulsion pump was 15 μL / min, and the receiving distance was 15cm.

[0039] The as-spun fibers obtained above were calcined in an air atmosphere with a heating rate of 2° C. / min and a calcination temperature of 500° C. After 6 hours of heat preservation, the temperature was naturally lowered to obtain alumina nanofibers.

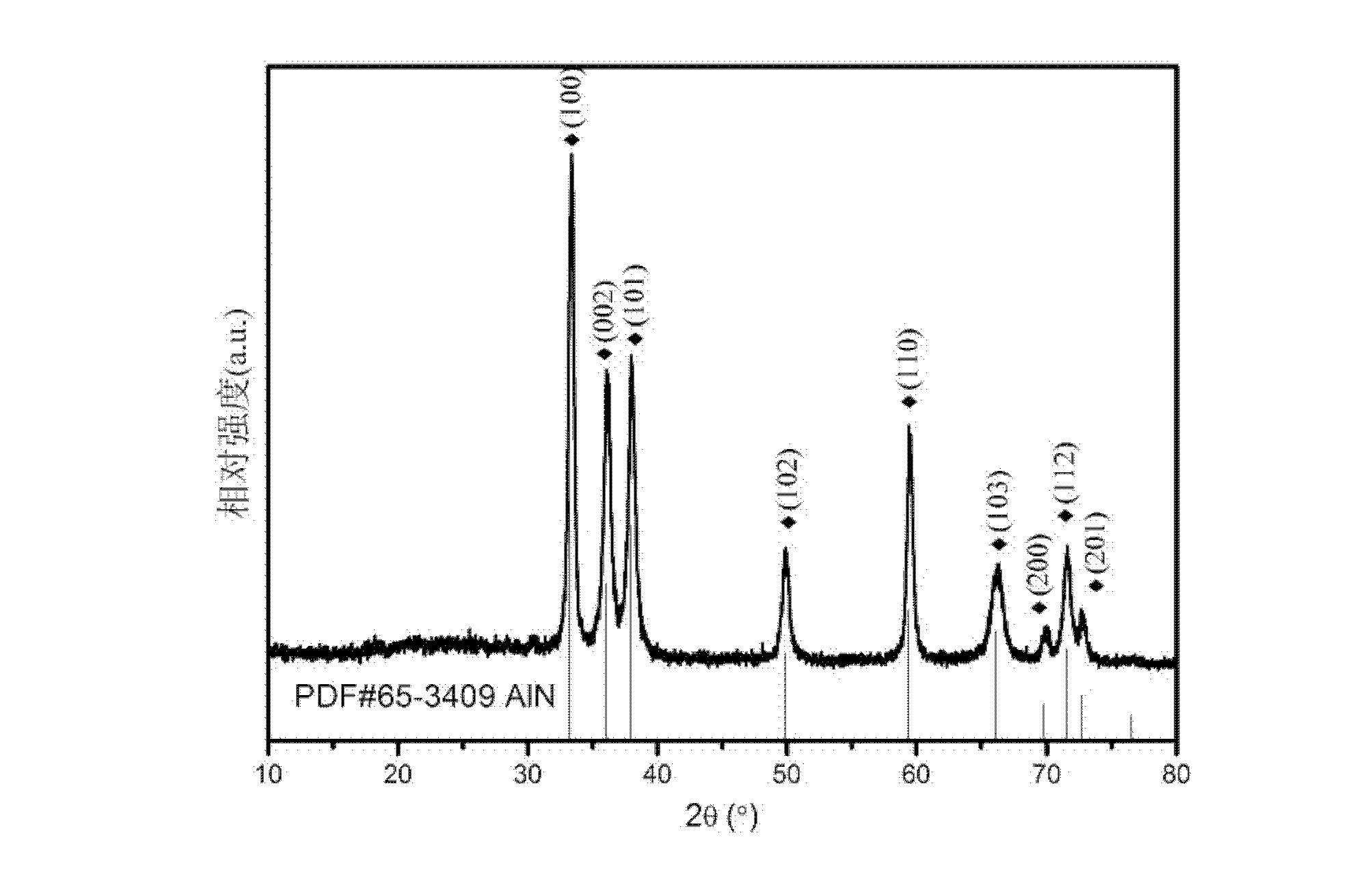

[0040] The calcined fibers were transferred to a tube-type atmosphere furnace, and ammonia gas was introduced. The flow rate of ammonia gas was 400mL / min, and the heating rate of ...

Embodiment 2

[0043]Take 3ml of deionized water and 7ml of absolute ethanol and mix evenly. Dissolve 0.75g of aluminum nitrate in the hydroalcoholic solution; then add 0.95g of polyvinylpyrrolidone (number average molecular weight: 1,300,000) to the above solution, and stir until the solution becomes clear and transparent.

[0044] The obtained precursor solution was electrospun: at room temperature, the humidity was controlled at 25%, the spinning voltage was set to 10kv, the propulsion speed of the propulsion pump was 15 μL / min, and the acceptance distance was 15cm.

[0045] The as-spun fibers obtained above were calcined in an air atmosphere with a heating rate of 3° C. / min and a calcination temperature of 600° C. After holding for 4 hours, the temperature was naturally lowered to obtain alumina nanofibers.

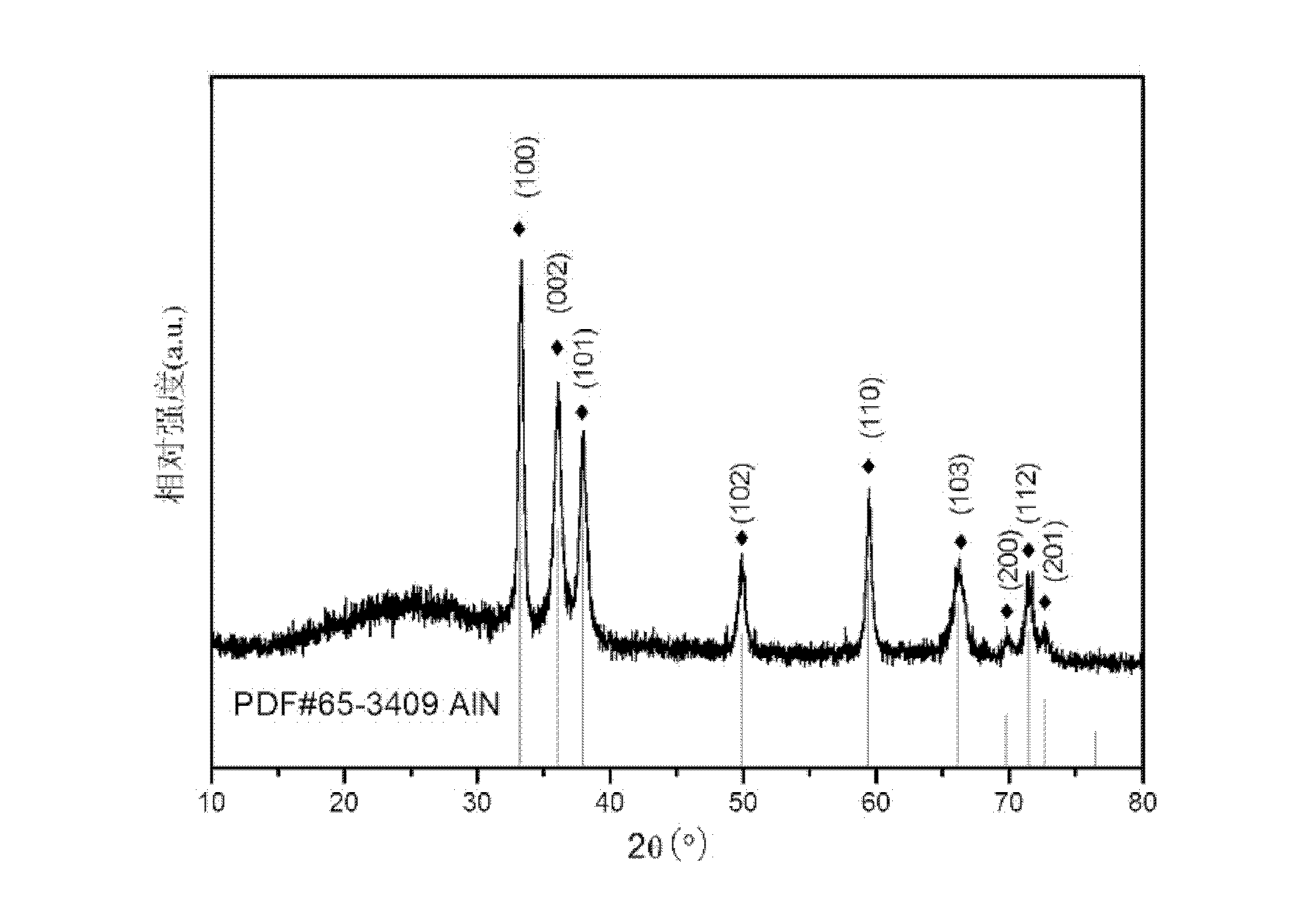

[0046] The calcined fibers were transferred to a tube-type atmosphere furnace, and ammonia gas was introduced. The flow rate of ammonia gas was 400mL / min. The heating rate of the tu...

Embodiment 3

[0049] Take 3ml of deionized water and 7ml of absolute ethanol and mix evenly; dissolve 0.75g of aluminum nitrate in the hydroalcoholic solution; then add 0.95g of polyvinylpyrrolidone (number average molecular weight 1300000) to the above solution, and stir until the solution becomes clear transparent.

[0050] The obtained precursor solution was electrospun: at room temperature, the humidity was controlled at 25%, the spinning voltage was set to 10kv, the propulsion speed of the propulsion pump was 15 μL / min, and the acceptance distance was 15cm.

[0051] The as-spun fibers obtained above were calcined in an air atmosphere with a heating rate of 1° C. / min and a calcination temperature of 500° C. After 6 hours of heat preservation, the temperature was naturally lowered to obtain alumina nanofibers.

[0052] The calcined fibers were transferred to a tube-type atmosphere furnace, and ammonia gas was introduced. The flow rate of ammonia gas was 400mL / min. The heating rate of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com