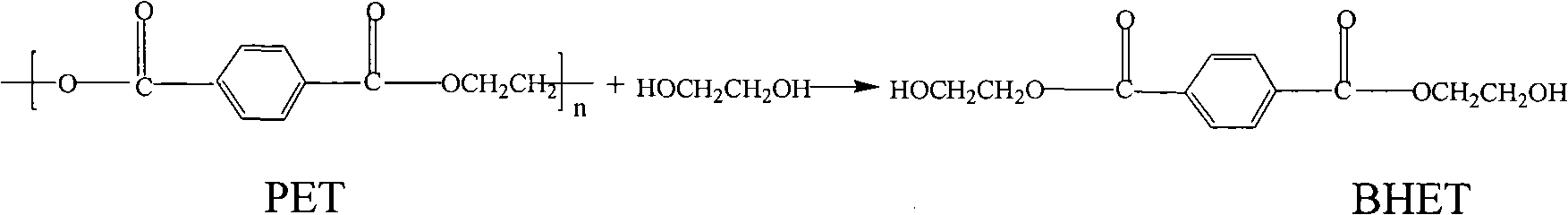

Method for catalyzing alcoholysis performed on polyethylene glycol terephthalate (PET) by using CoCl42-/NiCl42-type ionic liquid

A technology of polyethylene terephthalate and ethylene phthalate, which is applied in the field of green and clean catalysis, can solve the problems of difficult separation of catalyst and product, difficulty of catalyst recycling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Implementation method: in a 50ml three-necked flask, add 5.0g PET particles, PET particles with a size of 2.2×2.5×2.7mm, 20.0g ethylene glycol and 2.0g 1-butyl-3-methylimidazole cobalt tetrachloride ([ bmim] 2 CoCl 4 ). Control the reaction temperature to 170° C., the pressure to 1 atm, condense and reflux for 4 hours and then cool to room temperature. Under these conditions, the degradation rate of PET polyester is 100%, the selectivity of monomer ethylene terephthalate (BHET) is 80.0%, and the mass percentage of monomer in the product is 91.5%.

Embodiment 2

[0027] With embodiment 1, the catalyst that adds is 2.0g 1-butyl-3-methylimidazole nickel tetrachloride salt ([bmim] 2 NiCl 4 ). Under these conditions, the degradation rate of PET polyester is 45%, the selectivity of monomer ethylene terephthalate (BHET) is 64.3%, and the mass percentage of monomer in the product is 74.7%.

Embodiment 3

[0029] Implementation method: in a 50ml three-necked flask, add 5.0g PET particles, PET particles with a size of 12 mesh, 20.0g ethylene glycol and 2.0g 1-butyl-3-methylimidazole cobalt tetrachloride ([bmim] 2 CoCl 4 ). Control the reaction temperature at 170°C and the pressure at 1 atm, condense and reflux for 1.5 hours and then cool to room temperature. Under these conditions, the degradation rate of PET polyester is 100%, the selectivity of monomer ethylene terephthalate (BHET) is 79.2%, and the mass percentage of monomer in the product is 89.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com