Rheology modifying agent and preparation method thereof

A technology of modifying agent and initiator, applied in the direction of coating, etc., can solve the problems that the rheological agent cannot effectively prevent the flocculation of coating particles, cannot be coated, and the viscosity increases, so as to improve the paper covering performance and gloss, Improved fluidity and increased solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of a rheology modifier, which comprises the following steps: 1) under stirring conditions, acrylic monomers and functional monomers are polymerized in an aqueous solution under the action of an initiator; 2) step 1 ) adjusting the pH value of the polymerized solution to 6.0-8.0; and 3) keeping warm, stopping stirring, and discharging to obtain a rheology modifier.

[0020] According to an embodiment of the present invention, the acrylic monomer is selected from at least one of acrylic acid (AA), methacrylic acid (MAA), itaconic acid, and fumaric acid.

[0021] According to one embodiment of the present invention, the functional monomer is selected from maleic anhydride (MA), acrylamide (AM), sodium allyl sulfonate, 2-hydroxyethyl methacrylate (HEMA), 2-acrylic acid At least one of hydroxyethyl ester (HEA), sodium methacrylsulfonate, N-methylolacrylamide, and 2-acrylamido-2-methylpropenesulfonic acid (AMPS).

[0022] According...

Embodiment 1

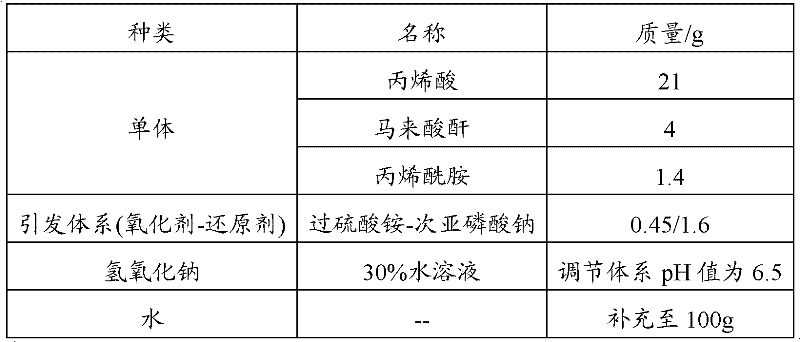

[0029] According to the composition and content shown in Table 1, the rheology modifier of the present invention is prepared according to the following method, and the specific steps are: 1) Add water, 4 g of maleic anhydride, and 1.6 g of sodium hypophosphite in a 250 ml reactor, and start stirring to dissolve Raise the temperature to 75°C; 2) After completely dissolving and keeping the temperature constant, add the mixed monomer (acrylic acid 21g, acrylamide 1.4g, water) and initiator ammonium persulfate aqueous solution 0.45g dropwise, and add dropwise in 2-2.5h; 3 ) After finishing the dropwise addition, keep it warm for 3 hours, then lower the temperature to 45°C, and use 30% sodium hydroxide solution to adjust the pH value to 6.5; agent.

[0030] Table 1: Composition and content of embodiment 1

[0031]

Embodiment 2

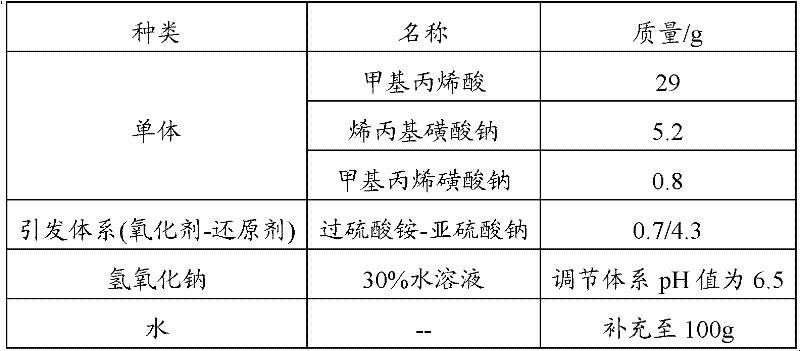

[0033] Prepare rheology modifier of the present invention according to the composition and content shown in table 2, concrete steps are: 1) add water, allyl sodium sulfonate 5.2g, sodium bisulfite 4.3g in 250ml reactor , start stirring and dissolving and heat up to 75°C; 2) After completely dissolving and keeping the temperature constant, add the mixed monomer (methacrylic acid 29g, sodium methacrylate sulfonate 0.8g, water) and initiator ammonium persulfate aqueous solution 0.7g , 2-2.5h dropwise addition; 3) After completion of dropwise addition, keep warm for 2h, then lower the temperature to 45°C, adjust the pH value to 7.0 with 30% sodium hydroxide solution; 4) After adjusting the pH value, keep warm for 0.5h, stop Stir and discharge to obtain a rheology modifier.

[0034] Table 2: Composition and content of embodiment 2

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com