Halogen-free flame retardant composition for polyesters and application method thereof

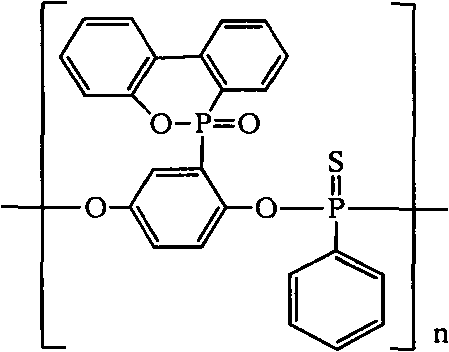

An application method and flame retardant technology, applied in the field of halogen-free flame retardant compositions for polyester PET and PBT, can solve the problems of poor compatibility with polymers, high volatility, poor heat resistance, etc., and achieve easy dispersion , the preparation method is simple, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

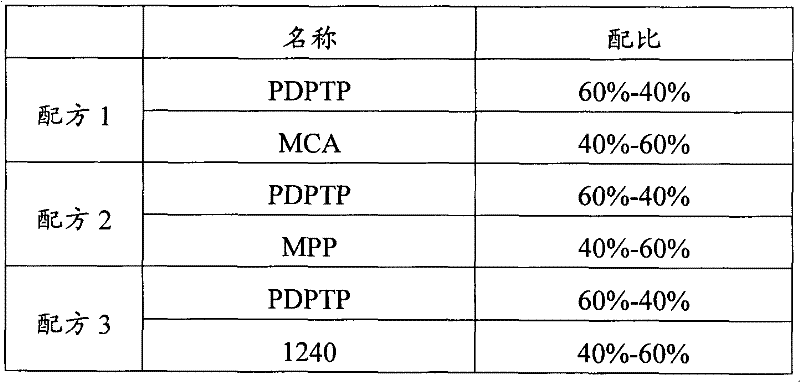

[0028] Example 1 Add different proportions of PDPTP to polyester PET, stir evenly, extrude a sample strip with a diameter of about 3 mm at the melting temperature with an extruder, and measure its oxygen index with a HC900-2 oxygen index measuring instrument. The results are shown in Table 2.

[0029] Table 2 Effect of the amount of flame retardant PDPTP on the oxygen index of PET

[0030] Amount added%

Embodiment 2

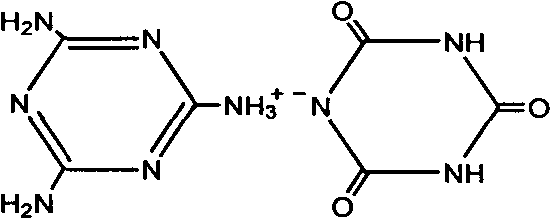

[0031] Example 2: Add different proportions of PDPTP and MCA to polyester PET, stir evenly, extrude a sample strip with a diameter of about 3 mm at the melting temperature with an extruder, and measure its oxygen index with a HC900-2 type oxygen index measuring instrument. The results are shown in Table 3.

[0032] Table 3 Effect of flame retardant PDPTP and MCA dosage on PET oxygen index

[0033]

Embodiment 3

[0034] Example 3 Add different proportions of PDPTP and MPP to polyester PET, stir evenly, extrude a sample strip with a diameter of about 3 mm at the melting temperature with an extruder, and measure its oxygen index with a HC900-2 type oxygen index measuring instrument. The results are shown in Table 4.

[0035] Table 4 Effect of flame retardant PDPTP and MPP dosage on PET oxygen index

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com