Thermosetting resin composition, prepreg prepared from composition, and laminated board prepared from composition and used for printed circuit board

A resin composition, thermosetting technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of insufficient moisture resistance and chemical resistance, and achieve good processability, excellent metal Effect of foil peel strength, high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

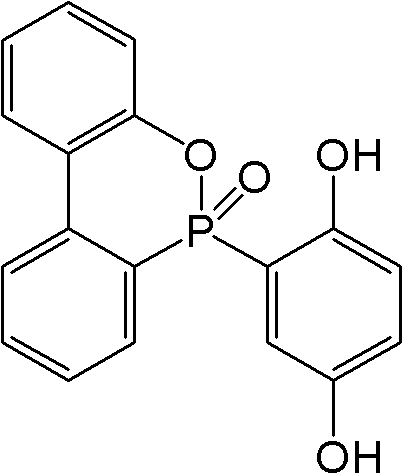

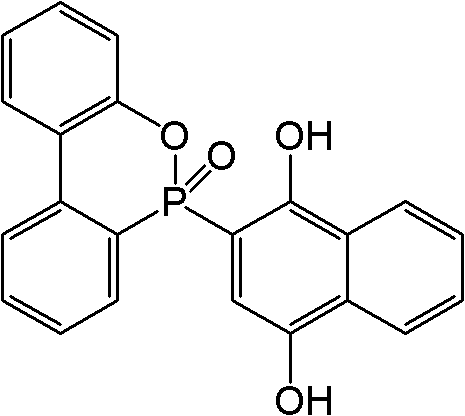

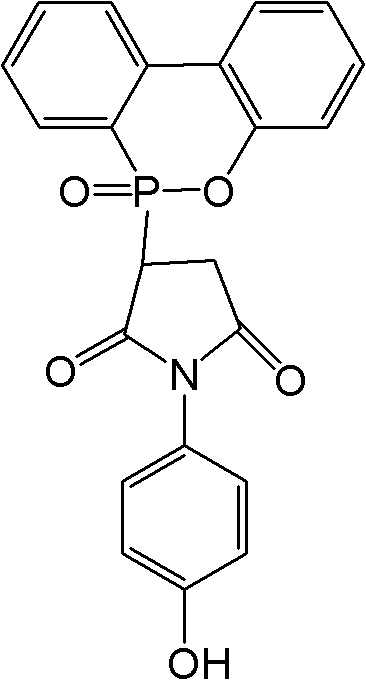

[0041] 50 parts of polyphenylene ether resin (Asahi Kasei Chemical Co., Ltd., trade name: S201A) with a number average molecular weight of 20000 and 50 parts of dicyclopentadiene epoxy resin (Changchun Artificial Resin Factory Co., Ltd., trade name: DNE260) were added to In 120 parts of toluene, stir and heat to 90°C to dissolve completely, then fully disperse 10 parts of DOPO-HQ (Huizhou Shengshida Technology Co., Ltd., trade name: ODOPB) in the reaction material, and then 8 parts of BPO (Dongguan Kangxin reagent, trade name: benzoyl peroxide) is divided into 10 parts and put into it evenly within 30 minutes. After 90 minutes of heat preservation at 90°C, stop heating. When the temperature drops to around 40°C, add 50 parts of bisphenol A type cyanate ( Jiangdu Wuqiao Resin Factory, trade name: CY-10), 0.02 parts of zinc isooctanoate and 30 parts of phosphazene flame retardant (Huizhou Shengshida Science and Technology Co., Ltd., trade name: SPB100), after stirring evenly, glu...

Embodiment 2

[0043] 50 parts of polyphenylene ether resin (Asahi Kasei Chemical Co., Ltd., trade name: S201A) with a number average molecular weight of 20000 and 50 parts of bisphenol A type epoxy resin (Dow Chemical, trade name: D.E.R.330) were added to 120 parts of toluene , stir and heat to 90°C to dissolve completely, then fully disperse 10 parts of DOPO-HQ (Huizhou Shengshida Technology Co., Ltd., trade name: ODOPB) in the reaction material, and then 8 parts of BPO (Dongguan Kangxin Reagent , product name: benzoyl peroxide) is divided into 10 parts and put into it evenly within 30 minutes. After 90 ℃ heat preservation for 90 minutes, stop heating, and when the temperature drops to around 40 ℃, add 50 parts of bisphenol A type cyanate Resin factory, trade name: CY-10), 0.02 parts of zinc isooctanoate and 30 parts of phosphazene flame retardant (Huizhou Shengshida Technology Co., Ltd., trade name: SPB100), after stirring evenly, glue is obtained. Take flat and smooth E-type glass fiber ...

Embodiment 3

[0045] 50 parts of polyphenylene ether resin with a number average molecular weight of 20000 (Asahi Kasei Chemical Co., Ltd., trade name: S201A) and 50 parts of biphenyl type epoxy resin (Nippon Kayaku Co., trade name: NC3000H) were added to 120 parts of toluene , stirred and heated to 90°C to dissolve completely, then 10 parts of DOPO-HQ (Huizhou Shengshida Technology Co., Ltd., trade name: ODOPB) was fully dispersed in the reaction material, and then 8 parts of BPO (Dongguan Kangxin Reagent, Product name: benzoyl peroxide) is divided into 10 parts and put into it evenly within 30 minutes. Stop heating after 90°C for 90 minutes, and add 50 parts of bisphenol A cyanate (Jiangdu Wuqiao Resin factory, trade name: CY-10), 0.02 parts of zinc isooctanoate and 30 parts of phosphazene flame retardant (Huizhou Shengshida Technology Co., Ltd., trade name: SPB100), after stirring evenly, obtain glue. Take flat and smooth E-type glass fiber cloth of model 2116 and evenly impregnate the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com