Non-dependent production method of gamma-polyglutamic acid from glutamic acid

A technology of polyglutamic acid and production method, applied in the field of biological sciences, can solve the problems of high raw material cost, unsuitable for industrial scale production, low production efficiency, etc., and achieve the effects of increased output, easy operation, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The glutamate-independent production method of γ-polyglutamic acid comprises the following steps: step 1) strain activation: streak Bacillus subtilis C10 on a plate, culture at 37° C. for 12 hours. The plate medium consists of: peptone 10g / L, beef extract 5g / L, sodium chloride 5g / L, glucose 10g / L, agar 15g / L, pH 7.

[0021] Step 2) Preparation of seeds: pick the activated Bacillus subtilis (Bacillus subtilis) C10 bacterial classification and insert it into the liquid seed culture medium, the liquid filling volume is 20ml culture medium in a 250ml Erlenmeyer flask, 37°C, 200rpm (rev / min), Shake culture for 12h. The composition of the above seed medium: peptone 10g / L, beef extract 5g / L, sodium chloride 5g / L, glucose 10g / L, pH 7.

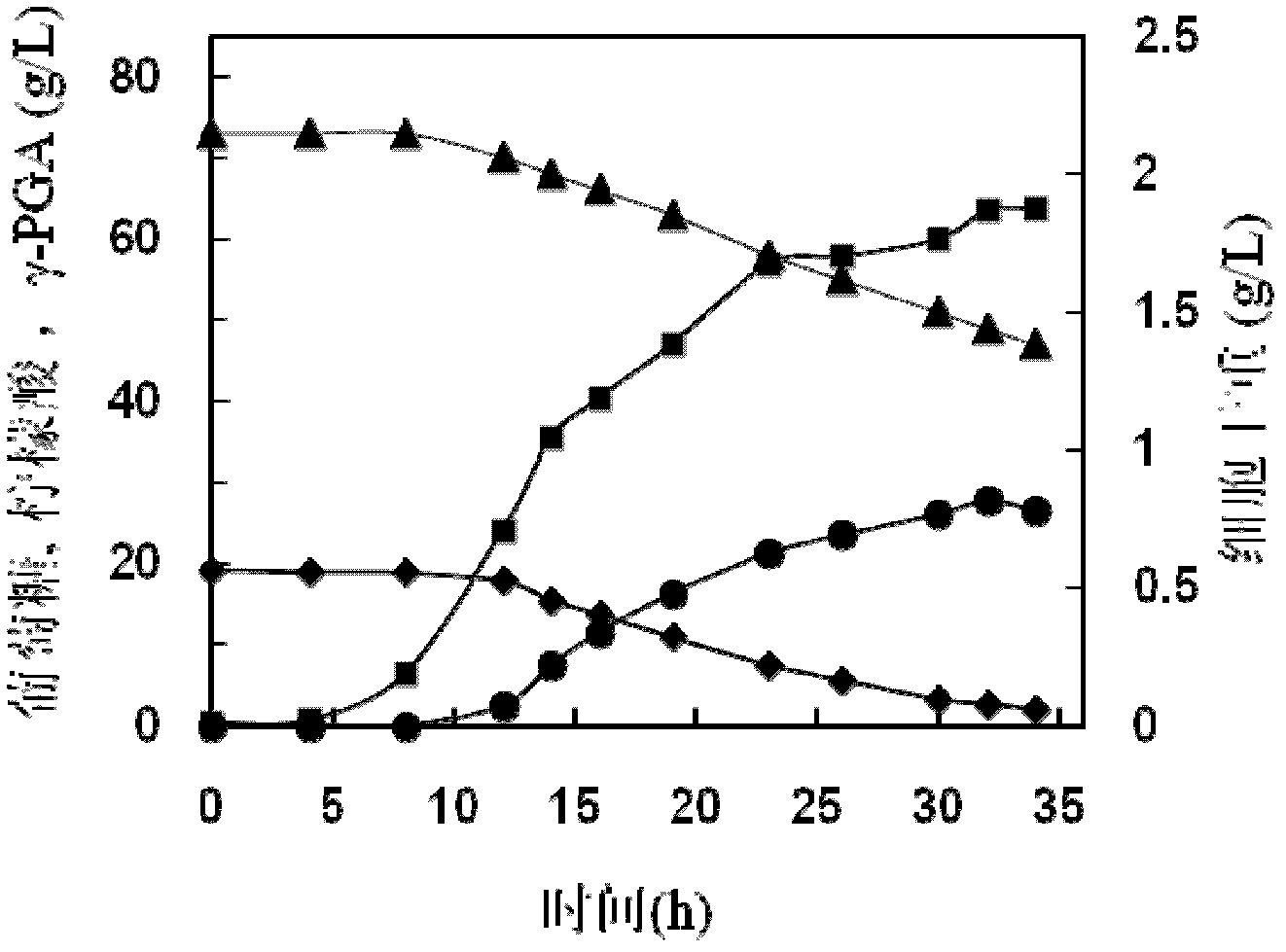

[0022] Step 3) Put the prepared seed liquid into a 10L fermenter at a ratio of 5%, the liquid content of the fermentation medium is 6L, and the fermentation parameters are controlled as follows: fermentation temperature 37°C, stirring 400rpm, p...

Embodiment 2

[0026] Step 1) is the same as step 1) in Example 1.

[0027] Step 2) is the same as step 2) in Example 1.

[0028] Step 3) and step 3 in embodiment 1) except following difference, all the other technical features are identical, and difference is that when citric acid concentration is lower than 5g / L in the fermentation medium, start to add the mixing of citric acid and ammonium chloride intermittently The concentration of the solution is 250g / L and 48g / l respectively, the concentration of citric acid in the maintenance medium is about 5-20g / L, and the concentration of ammonium chloride is 1-10g / L. Stop feeding when the concentration of γ-PGA in the medium no longer increases.

[0029] Step 4) is the same as step 4) in Example 1.

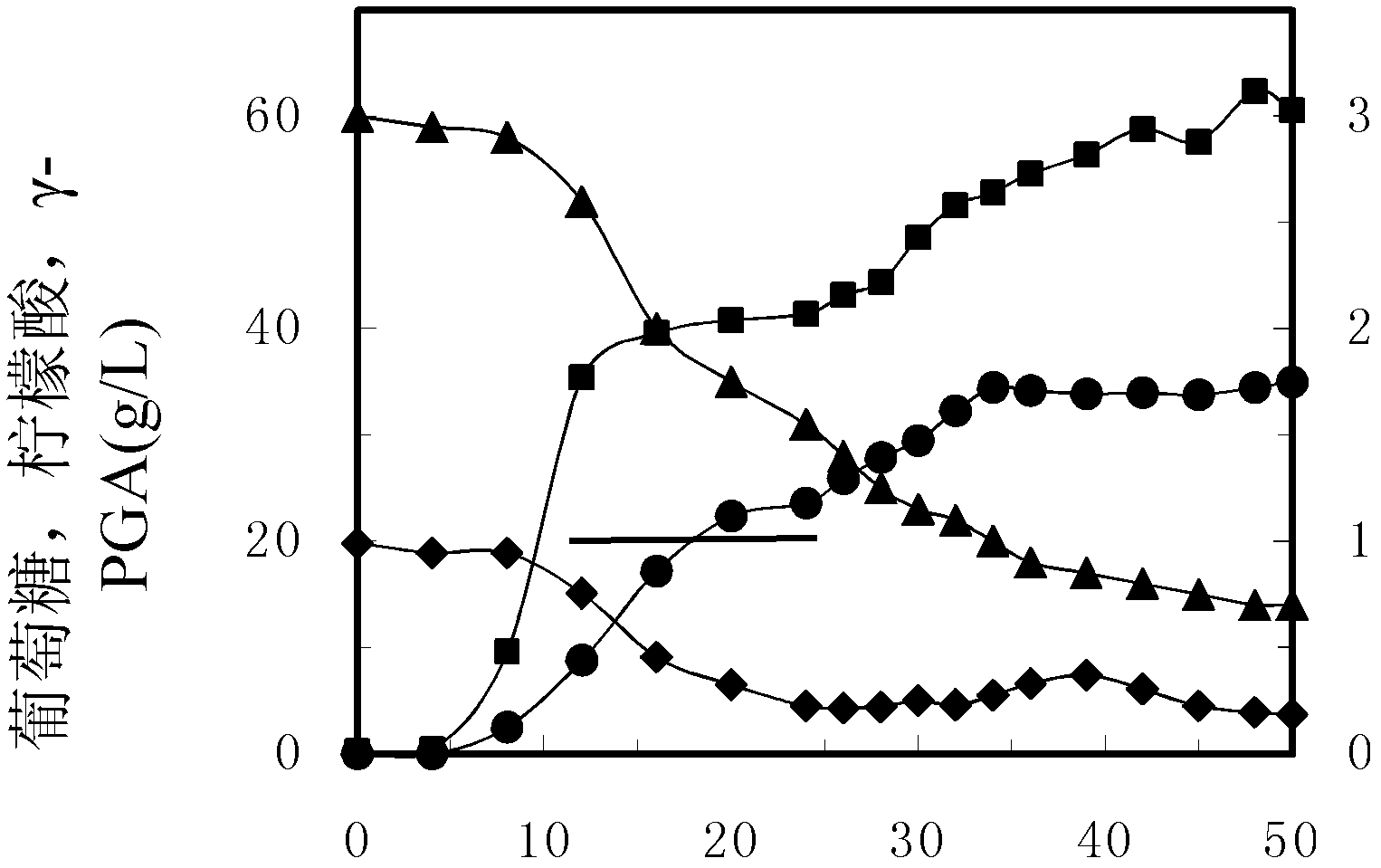

[0030] The fermentation results show that the final consumption of glucose is 57g / L, the consumption of citric acid is 29.8g / L, and the output of γ-PGA is 38.2g / L. The fermentation process curve is shown in image 3 .

Embodiment 3

[0041] Step 1) is the same as step 1) in Example 1.

[0042] Step 2) is the same as step 2) in Example 1.

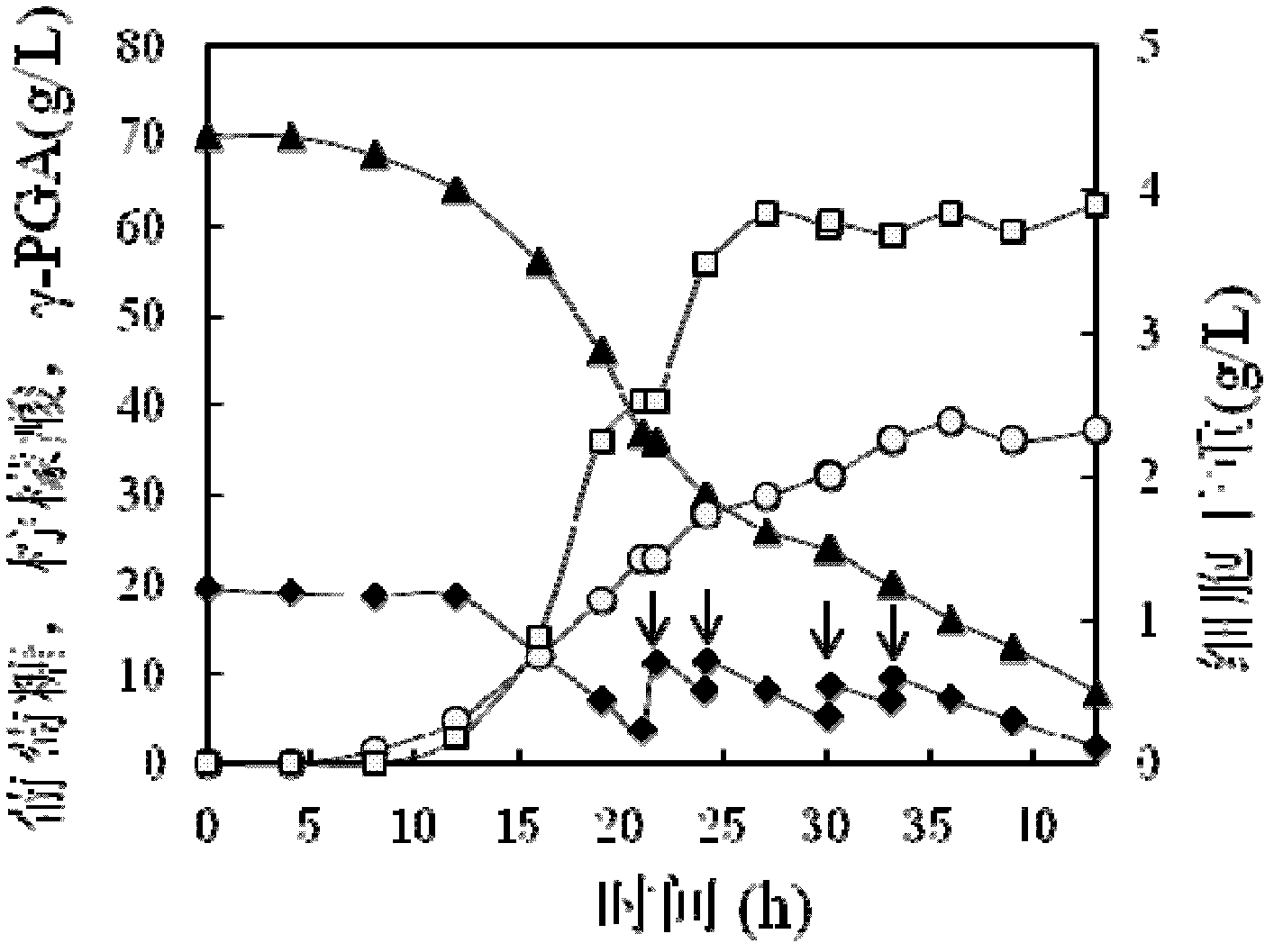

[0043] Step 3) Put the prepared seed liquid into a 10L fermenter at a ratio of 5%, the liquid content of the fermentation medium is 6L, and the fermentation parameters are controlled as follows: fermentation temperature 37°C, stirring 400rpm, pH 6.5, ventilation 0.4L / h. When the concentration of succinic acid in the fermentation medium is lower than 5g / L, start intermittently feeding sodium succinate solution with a concentration of 50g / L to maintain the concentration of succinic acid in the medium at about 5-10g / L. Stop feeding when the concentration of γ-PGA in the medium no longer increases.

[0044] The composition of the above fermentation medium: glucose 80g / l, ammonium chloride 10g / l, succinic acid 20g / l, KH2PO4 1.5g / l, MgSO4 7H2O 0.5g / l, FeCl3 0.05g / l, MnSO4 H2O 0.1g / l, CaCl2 0.11g / l, pH 6.5.

[0045] Step 4) is the same as step 4) in Example 1.

[0046] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com