Solid low-temperature pretreatment compound preparation

A compound preparation and low-temperature technology, applied in the field of fabric dyeing and finishing, can solve the problems of low energy consumption, achieve the effects of simplifying the process, reducing the overall cost and stabilizing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

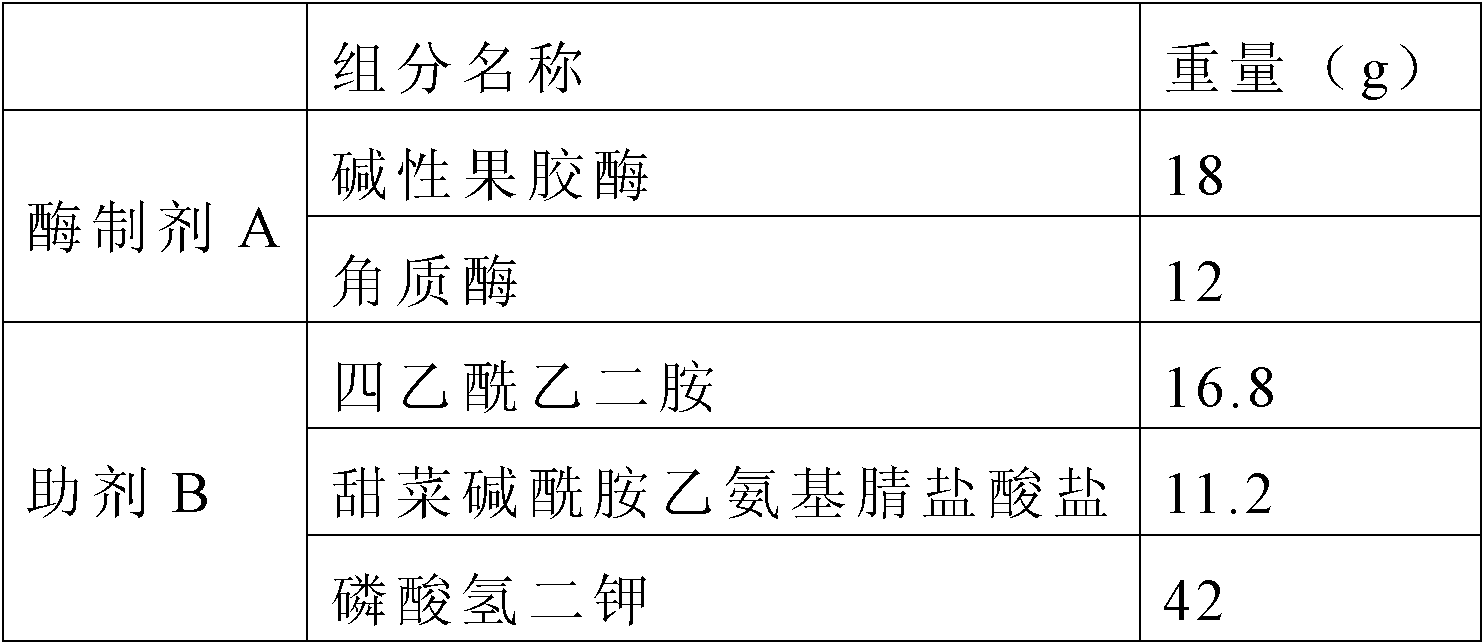

[0014] Prepare 100g of solid low-temperature pretreatment compound preparation according to the following ratio:

[0015]

[0016] Weigh the solids of each component according to the above table, and mix thoroughly to obtain the solid low-temperature pretreatment compound preparation 1.

[0017] In the solid low-temperature pretreatment compound preparation 1, the components and weight proportions are that the enzyme preparation A accounts for 30%, and the auxiliary agent B accounts for 70%.

[0018] The components and weight proportions in the enzyme preparation A are 60% of alkaline pectinase and 40% of cutinase.

[0019] The components and weight proportions of auxiliary agent B are 40% hydrogen peroxide activator and 60% phosphate. In the hydrogen peroxide activator, the components and weight proportions are 60% of tetraacetylethylenediamine (hydrogen peroxide acyl activator), and 40% of betaine amide ethylaminonitrile hydrochloride (hydrogen peroxide nitrile activator...

Embodiment 2

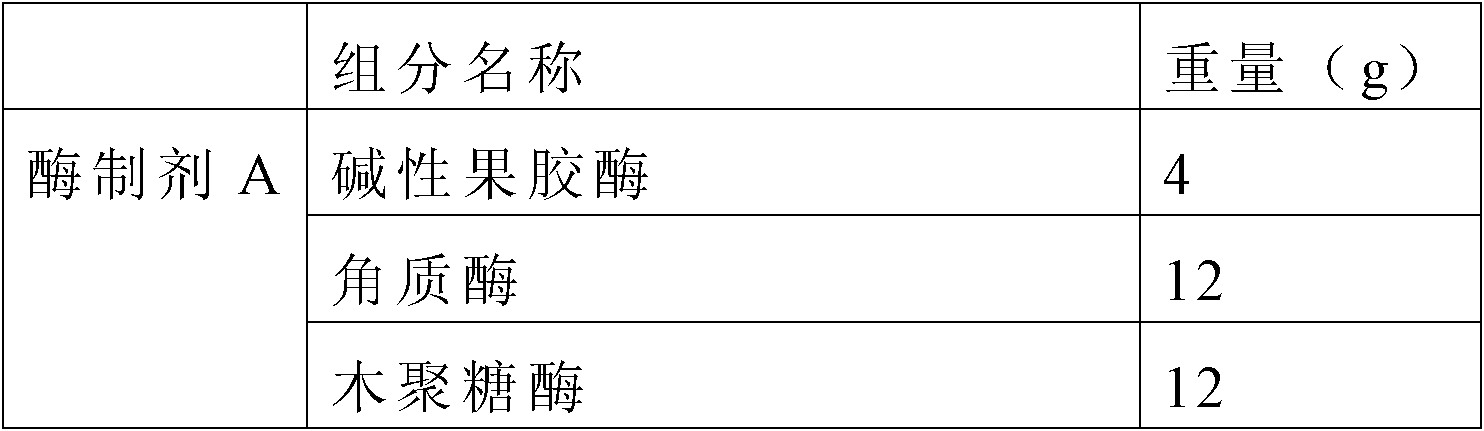

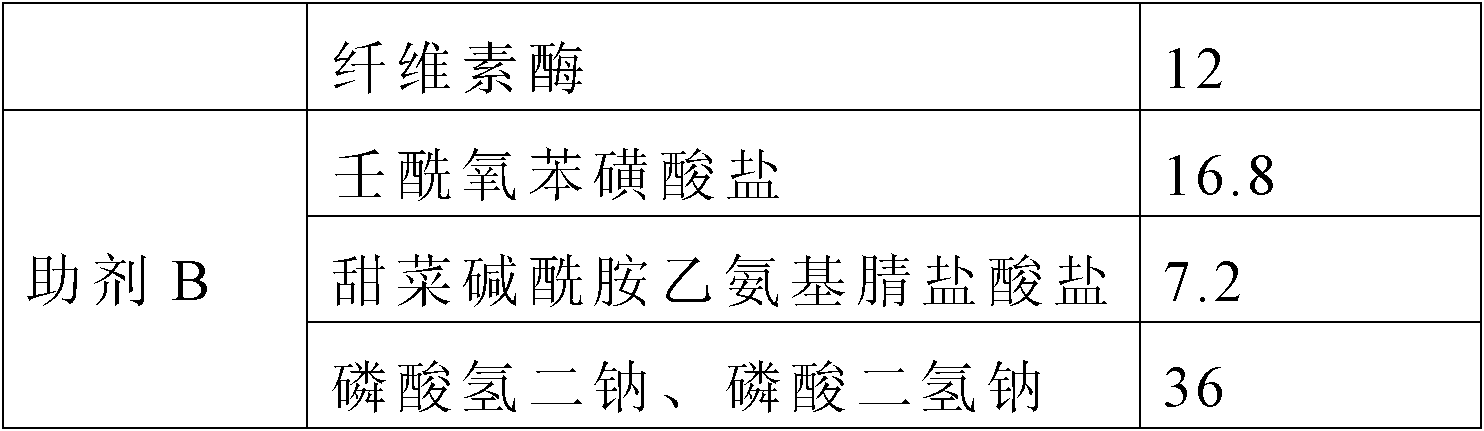

[0021] Prepare 100g of solid low-temperature pretreatment compound preparation according to the following ratio:

[0022]

[0023]

[0024] Weigh the solids of each component according to the above table, and mix thoroughly to obtain the solid low-temperature pretreatment compound preparation 2.

[0025] In the solid low-temperature pretreatment composite preparation 1, the components and weight proportions are that the enzyme preparation A accounts for 40%, and the auxiliary agent B accounts for 60%.

[0026] The components and weight proportions of the enzyme preparation A are 10% of alkaline pectinase, 30% of cutinase, 30% of xylanase and 30% of cellulase.

[0027] The components and weight proportions of auxiliary agent B are 40% hydrogen peroxide activator and 60% phosphate. The components and weight proportions of the hydrogen peroxide activator are 70% of nonanoyloxybenzenesulfonate (hydrogen peroxide acyl activator), and 30% of betaine amide ethylaminonitrile hy...

Embodiment 3

[0029] Prepare 100g of solid low-temperature pretreatment compound preparation according to the following ratio:

[0030]

[0031] Weigh the solids of each component according to the above table, and mix thoroughly to obtain the solid low-temperature pretreatment compound preparation 3.

[0032] In the solid low-temperature pretreatment compound preparation 1, the components and weight proportions are that the enzyme preparation A accounts for 20%, and the auxiliary agent B accounts for 80%.

[0033] The components and weight proportions in the enzyme preparation A are 70% of alkaline pectinase and 30% of cutinase.

[0034] The components and weight proportions of auxiliary agent B are 20% hydrogen peroxide activator and 80% phosphate. The components and weight proportions of the hydrogen peroxide activator are 30% of acetylated glucose (hydrogen peroxide acyl activator), and 70% of betaine amide ethylaminonitrile hydrochloride (hydrogen peroxide nitrile activator). Phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com